Method and water chutes for adjusting water-wet distribution of water-storage type evaporative cooling wall

An evaporative cooling and water guiding technology, applied in the field of water guiding channels, can solve the problem that a porous water storage body cannot fully absorb moisture, etc., and achieve the effect of simple structure and ingenious conception.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

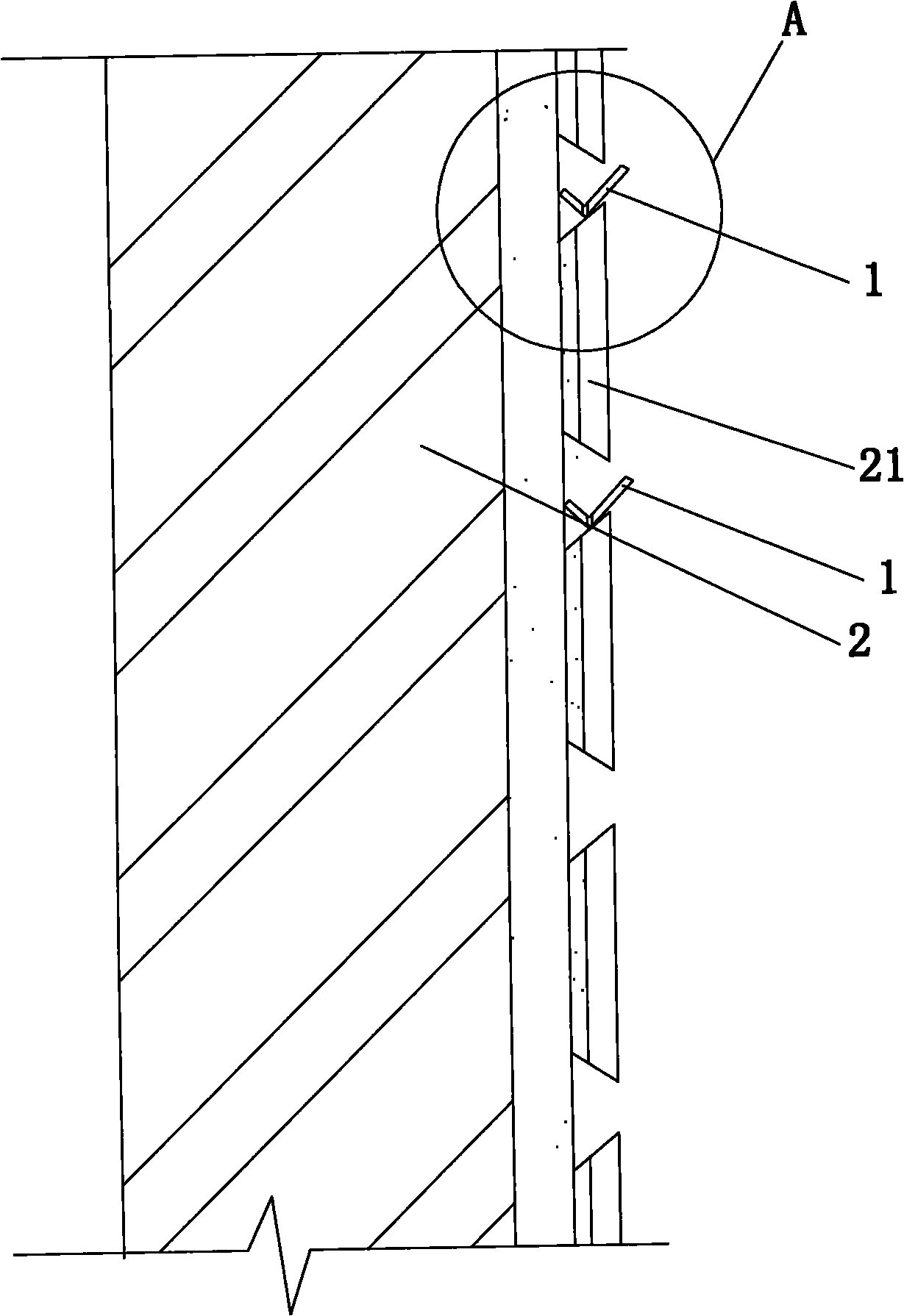

[0032] Example 1: see Figure 1 to Figure 9 , the present invention is a kind of method for regulating the water-humidity distribution of water-storage evaporation cooling wall body, and it comprises the following steps:

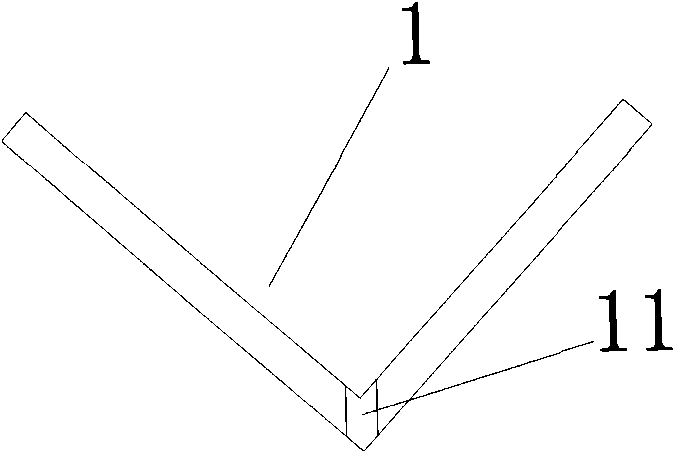

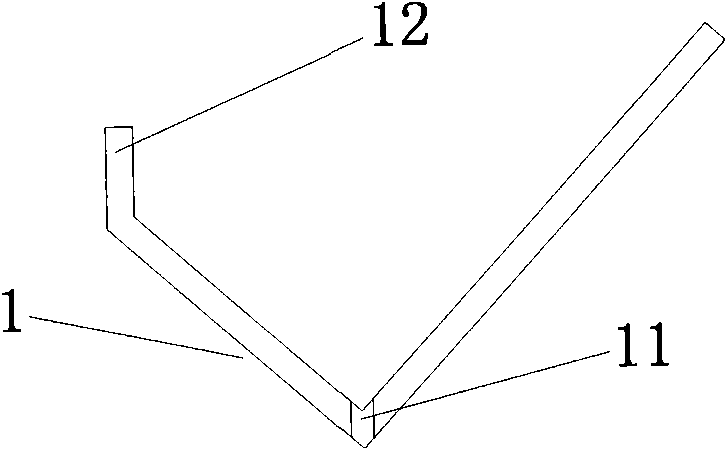

[0033] (1) Prepare some aqueducts 1, the section of which is unequal L-shaped, U-shaped or unequal trapezoid, the opening of the aqueduct 1 is wide and the bottom is narrow, and the bottom of the aqueduct 1 is intercepted from above A number of water outlet holes 11 are required to flow downward or guide the water flow from top to bottom;

[0034] (2) Place the opening of the water guiding channel 1 facing upwards in the horizontal joint of the decorative brick layer 21 of the water storage evaporation cooling wall 2 that needs to adjust the water humidity distribution;

[0035] (3) When the water flows from top to bottom, since one side of the water guide groove 1 is closely attached to the water storage evaporation cooling wall 2, the water flow is collec...

Embodiment 2

[0046] Example 2, see Figure 2 to Figure 10, this embodiment is mostly the same as Embodiment 1, the difference is that the opening of the water guiding groove 1 faces upwards, and it is stuck on the multi-level decorative brick layer 21 of the water storage evaporation cooling wall 2 that needs to adjust the water and humidity distribution. A multi-stage water guide groove 1 is formed in the seam, and the multi-stage transverse joints are arranged horizontally and distributed in parallel intervals; One side of the water tank 1 is closely attached to the water storage evaporative cooling wall 2, so the water flows through the surface of the facing brick layer 21 and then collects in the water guide channel 1 arranged in the lower transverse joint; A water outlet hole 11 is required for water flow or guiding water flow, so the water flow flows out from the set water outlet hole 11 again, flows through the surface of the facing brick layer 21 arranged at the lower part of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com