Pore plate cascade type heat exchange device

A heat exchange device, orifice plate stacking technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., to achieve the effect of saving metal materials, expanding application fields, and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

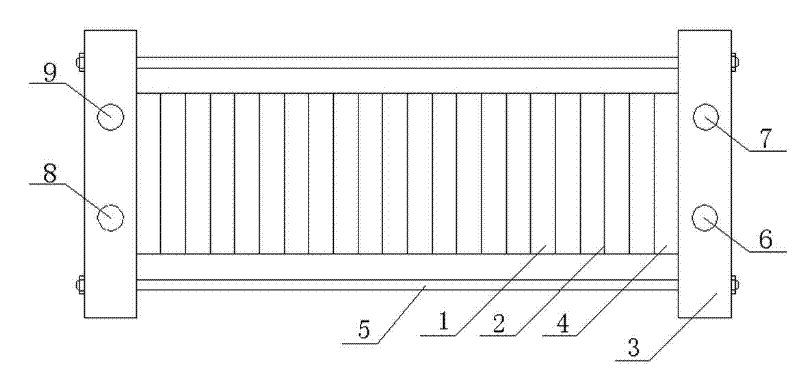

[0016] refer to figure 1 : In this embodiment, a porous plate 1 and a heat insulating pad 2 are stacked alternately to form an orifice heat exchange element. There are cold and hot fluid separators 3 at both ends of the orifice heat exchange element. A diversion channel plate 4 is arranged between the combiners, and they are fixed as an integral component by fastening screws 5 . A hot fluid inlet 6 and a cold fluid outlet 7 are arranged on the hot and cold fluid divider at the right end; a cold fluid inlet 8 and a hot fluid outlet 9 are arranged on the cold and hot fluid divider at the left end.

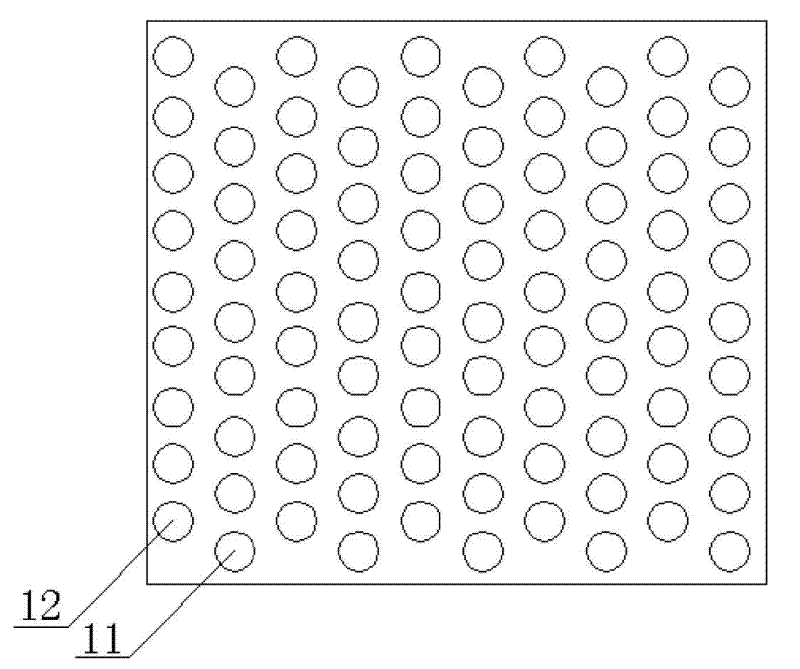

[0017] refer to figure 2 :

[0018] Several rows of hot fluid communication holes 11 and cold fluid communication holes 12 are arranged side by side on each porous plate.

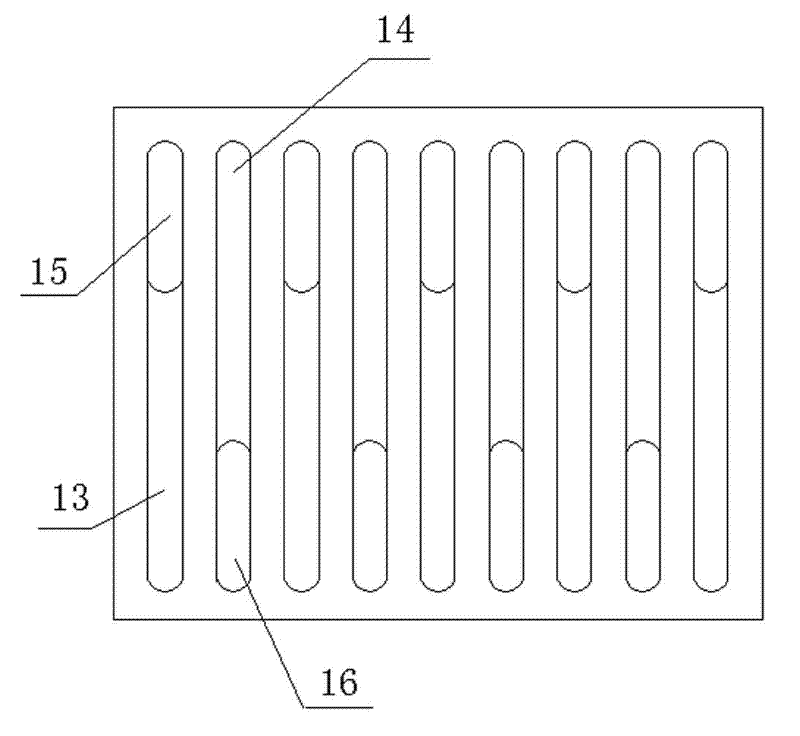

[0019] refer to image 3 :

[0020] There are several rows of cold diversion grooves 13 and heat diversion grooves 14 arranged staggered and parallel on the diversion groove plate; there are cold fluid throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com