Ultrasonic flow measuring device

A flow measuring device, ultrasonic technology, applied in measuring devices, measuring flow/mass flow, liquid/fluid solid measurement, etc., can solve problems such as easy blockage, achieve small changes in fluid flow paths, improve measurement accuracy, and reduce pressure loss small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

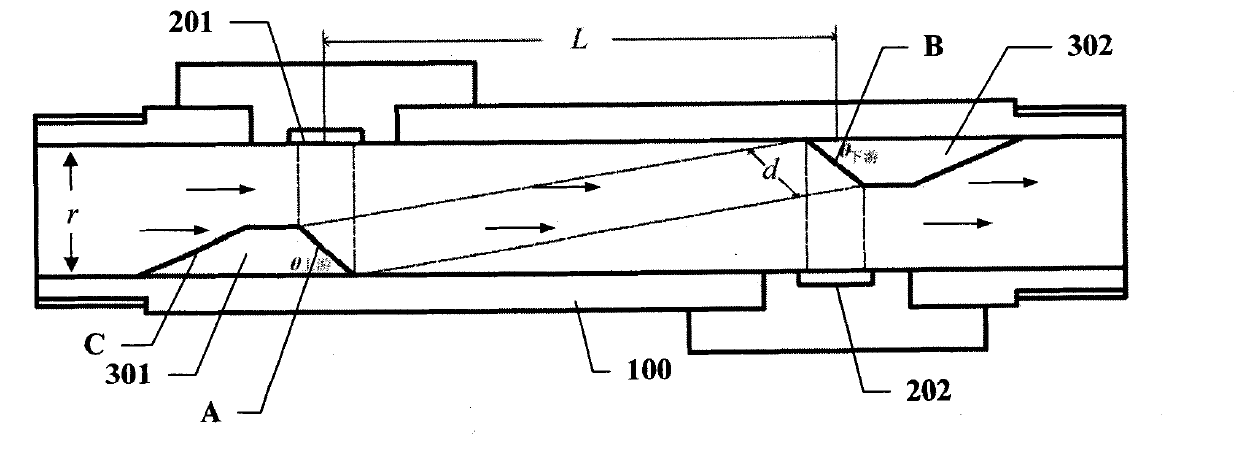

[0036] In this example, if figure 2 As shown, the ultrasonic flow measurement device includes a fluid pipeline 100 and upstream and downstream ultrasonic transducers 201 , 202 installed opposite to each other perpendicular to the pipe wall at a certain distance L on the inner pipe wall of the fluid pipe 100 . At the same time, a reflection block 301, 302 is installed directly opposite the upstream and downstream ultrasonic transducers 201, 202 in the fluid pipeline 100, and the reflection surface A of the upstream reflection block 301 forms an included angle θ of 35-43 degrees with the fluid inflow direction. 上游 , the angle θ between the reflection surface B of the downstream reflection block 302 and the fluid outflow direction is 35-45 degrees 下游 .

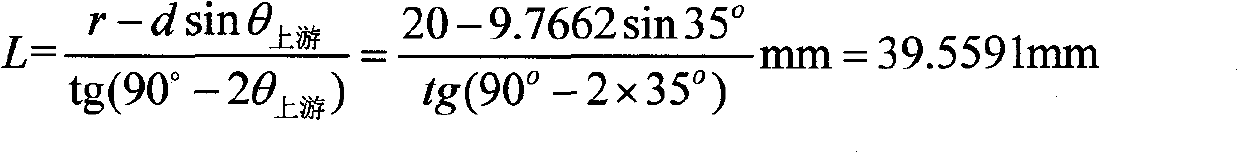

[0037] The spacing L approximately satisfies:

[0038]

[0039] Wherein, r is the inner diameter of the fluid pipe, and d is the length of the reflection surface of the reflection block.

[0040] like figure 2 As shown, wh...

example 1

[0043] In this example, if image 3 As shown, the inner diameter r of the fluid pipeline 100 is 20mm, and the included angle θ 下游 = Angle θ 上游 =40°, the projected length of reflective surfaces A and B on the fluid pipeline 100 is 8 mm, that is, the length d of the centerline of the reflective surface of the reflective block along the direction of fluid flow is:

[0044] d=8mm / cos40°=10.4433mm

[0045] The spacing L approximately satisfies:

[0046]

[0047] In this implementation, we can see that the reflective surfaces A and B increase the effective distance L of ultrasonic propagation to 75.3555mm, thereby improving the measurement accuracy.

[0048] In this implementation, if Figure 4 As shown, since the reflective block 301 is placed on the pipe wall, the distance from its center to the opposite pipe wall is 13.2872mm. It can be seen that the fluid flow area is relatively large, so that the ultrasonic flow measuring device of the present invention is not easy to de...

example 2

[0050] like Figure 5 As shown, in this implementation, except for the included angle θ 下游 = Angle θ 上游 =43°, other parameters are exactly the same as Example 1.

[0051] The length d of the center line of the reflective surface of the reflective block along the fluid flow direction is:

[0052] d=8mm / cos43°=10.9386mm

[0053] The spacing L approximately satisfies:

[0054]

[0055] Compared with Example 1, the included angle θ 上游 An increase of 3 degrees, but the spacing L increased by 103.9731mm, so if the angle θ 上游 After the angle is greater than 43 degrees, the processing accuracy requirements for the installation positions of the upstream and downstream ultrasonic transducers 201 and 202 and the upstream and downstream reflection blocks 301 and 302 are very high, so the included angle θ 上游 Less than or equal to 43 degrees.

[0056] In this implementation, if Image 6 As shown, the distance from the center of the reflection block 301 to the opposite pipe wall i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com