Multi-shaft DC servo motor control system and method based on EPA (Ethernet for Plant Automation) field bus

A DC servo and field bus technology, applied in the direction of electrical program control, electrical signal transmission system, comprehensive factory control, etc., can solve the problems of inability to realize direct centralized monitoring and seamless access, poor system scalability, and impossibility of realization, etc., to achieve Guaranteed determinism and real-time performance, good scalability, and collision avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

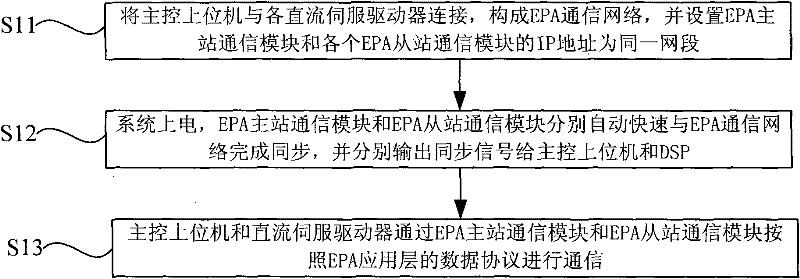

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0033] The core of the present invention is: adopting EPA field bus to connect the main control host computer and DC servo driver in the multi-axis DC servo motor control system, so that data exchange between them is carried out in the communication mode of EPA field bus. Therefore, the multi-axis DC servo motor control system has high-speed synchronization and high reliability communication performance, and can be easily integrated into the factory automation information network.

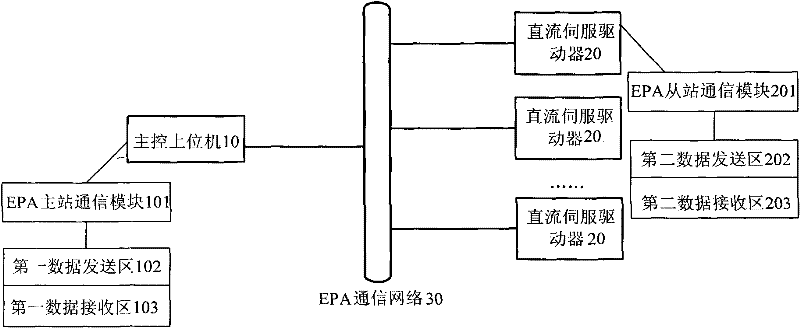

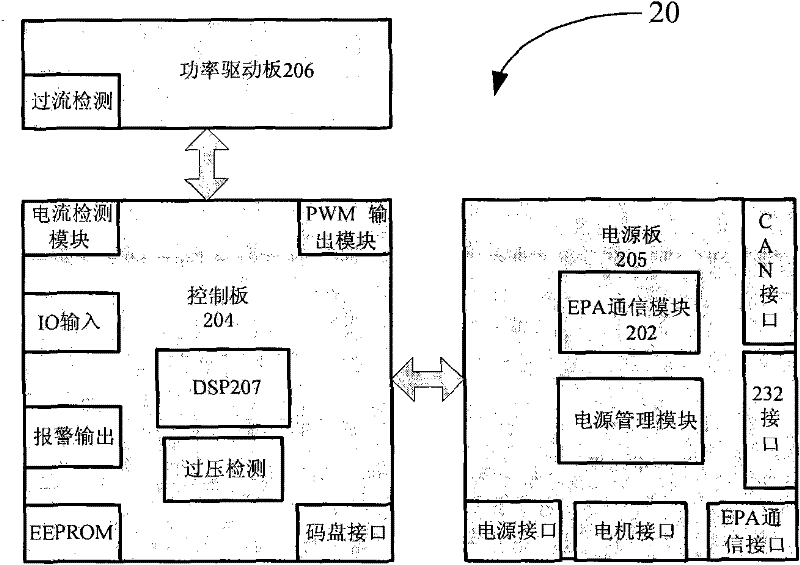

[0034] see figure 1 , a multi-axis DC servo motor control system based on EPA fieldbus, including a main control host computer 10 and a plurality of DC servo drives 20, the main control host computer 10 and the DC servo drives 20 are connected through an EPA communication network 30.

[0035] The main control host computer 10 includes an EPA master station communication module 101, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com