Inflatable protective device for sealing machine with energy-saving lamp tube

A protection device and sealing machine technology, which is applied in the manufacture of discharge tubes/lamps, electrical components, electric tubes/lamps off, etc., can solve the problems of increasing the contact area between the sealing head and the horn, high local heating, and lamp blackheads. , to reduce the early blackhead problem, avoid high temperature oxidation, and protect the head of the stem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

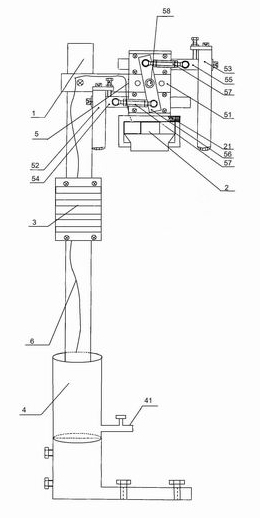

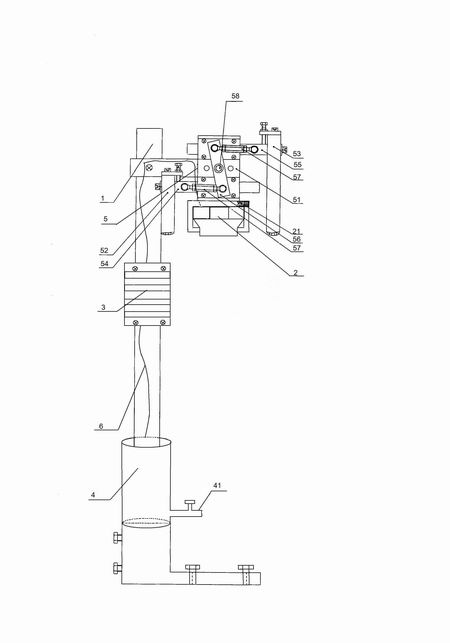

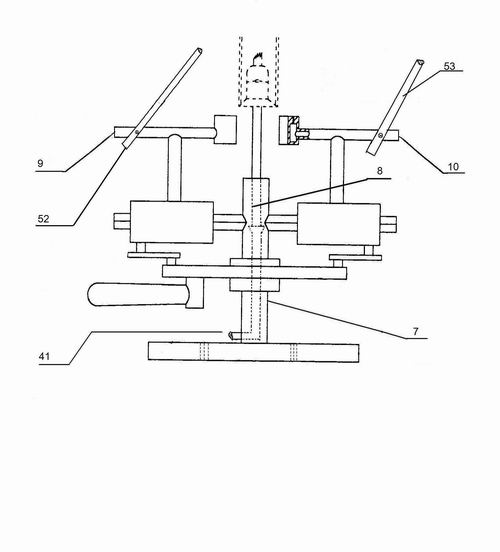

[0011] The inflatable protection device of the energy-saving lamp tube sealing machine, including the "匚" type main bracket 1, the proximity detection part 2 with the signal communication of the data line 6, the signal receiving control part 3 and the protective gas container 4, the linkage mechanism 5, the signal receiving The control part 3 and the protective gas container 4 are respectively fixed in the middle and lower parts of the column of the "匚" type main support 1, and the gas guide tube 41 of the protective gas container 4 extends into the stem shaft 7 of the sealing machine to exhaust the stem The pipe 8 is connected, and the top bracket of the "匚" type main bracket 1 is slidably installed with the setting part 51 of the linkage mechanism 5, and the proximity detection part 2 is fixed on the bottom of the setting part 51, and the periphery of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com