High-frequency structure and centering method for gyrotron amplifier

A high-frequency structure and amplifier technology, applied in the microwave field, can solve problems such as not being able to meet high average power, and achieve the effects of overcoming the inability to use high average power, improving stability, and improving output power and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

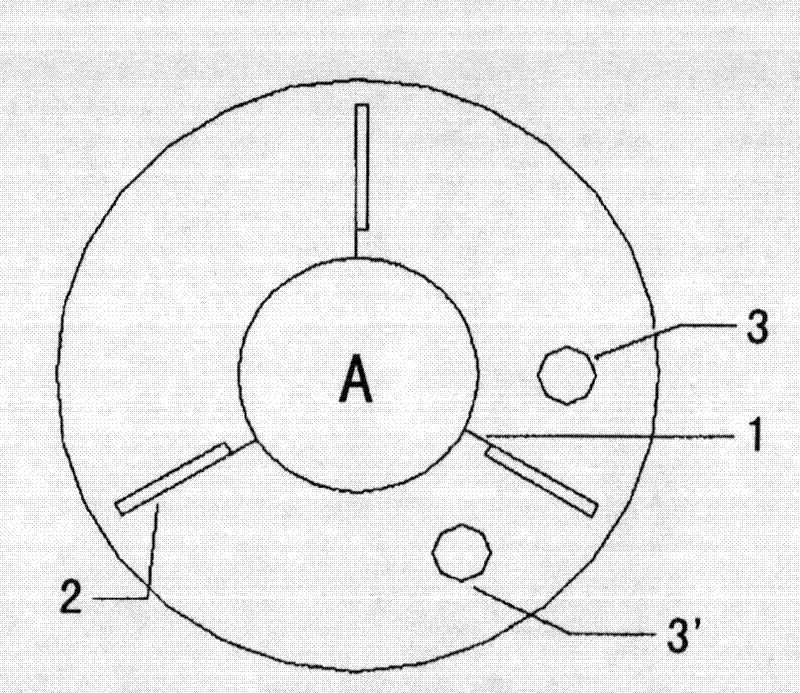

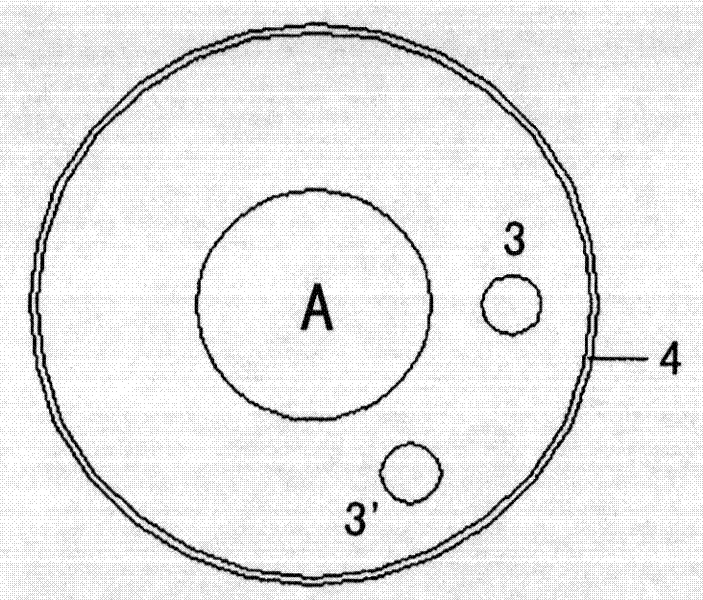

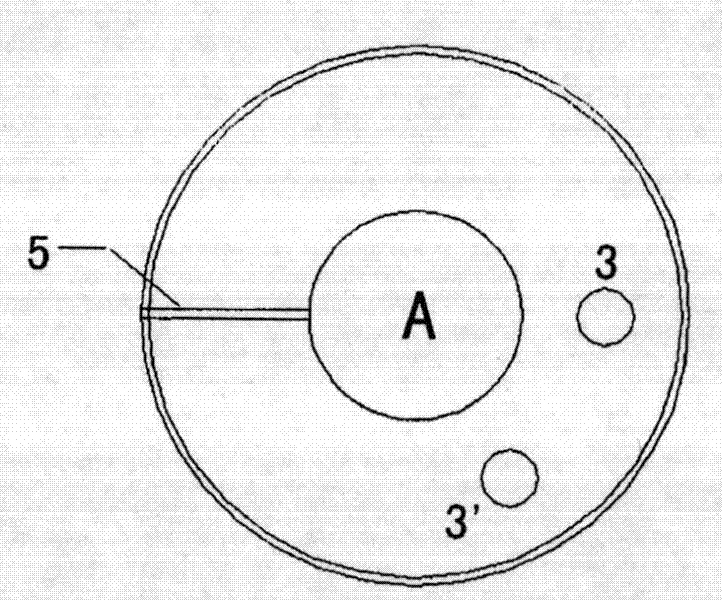

[0015] see figure 1 and figure 2 , the present invention is composed of smooth circular waveguides periodically arranged, each cycle length is composed of loaded circular waveguides and unloaded circular waveguides, and the length of loaded circular waveguides and unloaded circular waveguides can be adjusted according to the required attenuation. A plurality of coupling slots 1 are radiated uniformly along the central hole A on the loaded smooth circular waveguide. The number of coupling slots is not limited, and three are taken as an example in this embodiment. The direction of the coupling slot 1 corresponds to a cuboid attenuation ceramic 2 , and the function of the attenuation ceramic 2 is to absorb the high-frequency field leaked from the coupling slot 1 . There are also two centering holes 3, 3' on the loading circular waveguide, and the two centering holes 3, 3' are symmetrically distributed with the attenuation porcelain 2. The two centering holes present an angle o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com