Radiating device and manufacture method thereof

A technology of heat sink and radiator, applied in elastic/clamping device, cooling/ventilation/heating transformation, circuit arrangement on support structure, etc., can solve the problems of high cost, affect the normal operation of heat sink, etc., and achieve easy installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

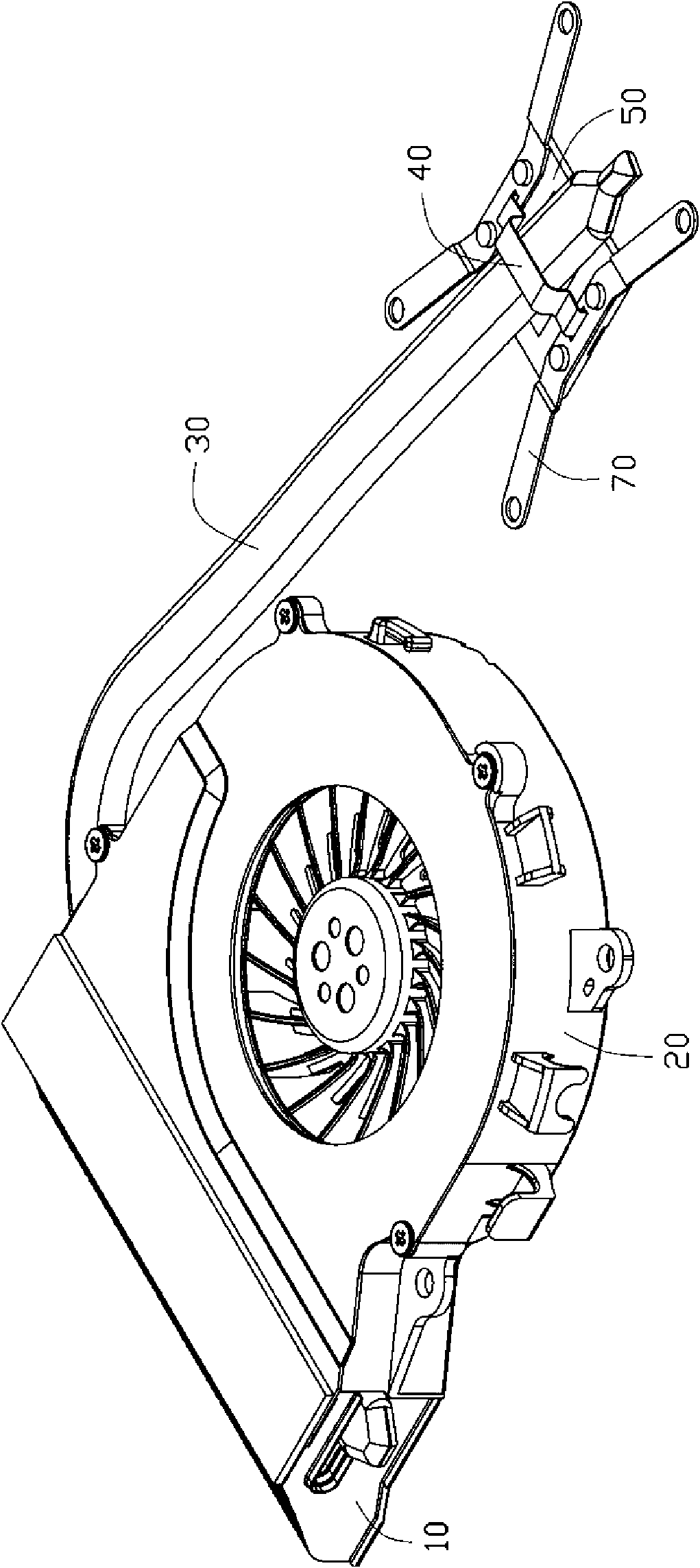

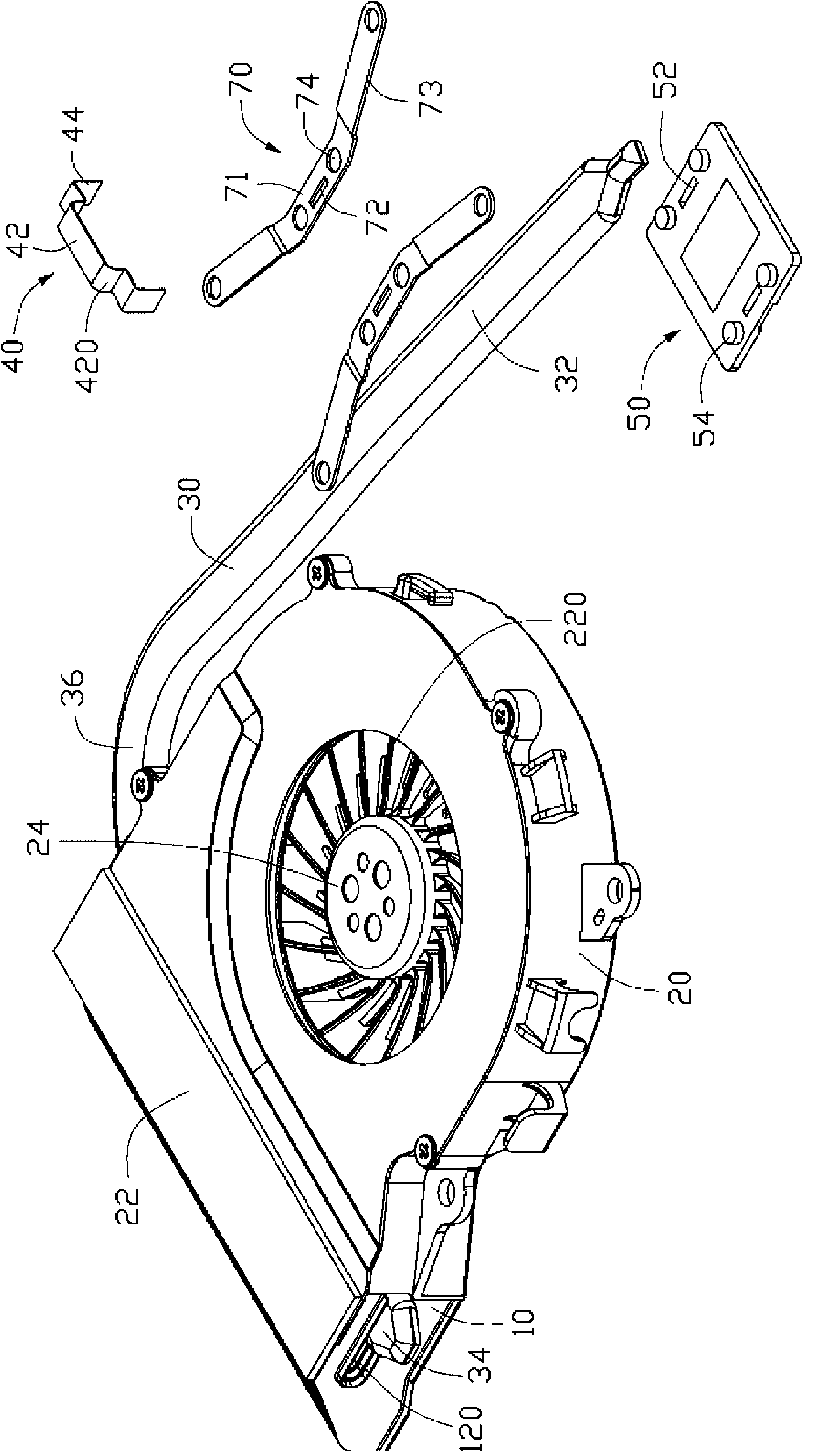

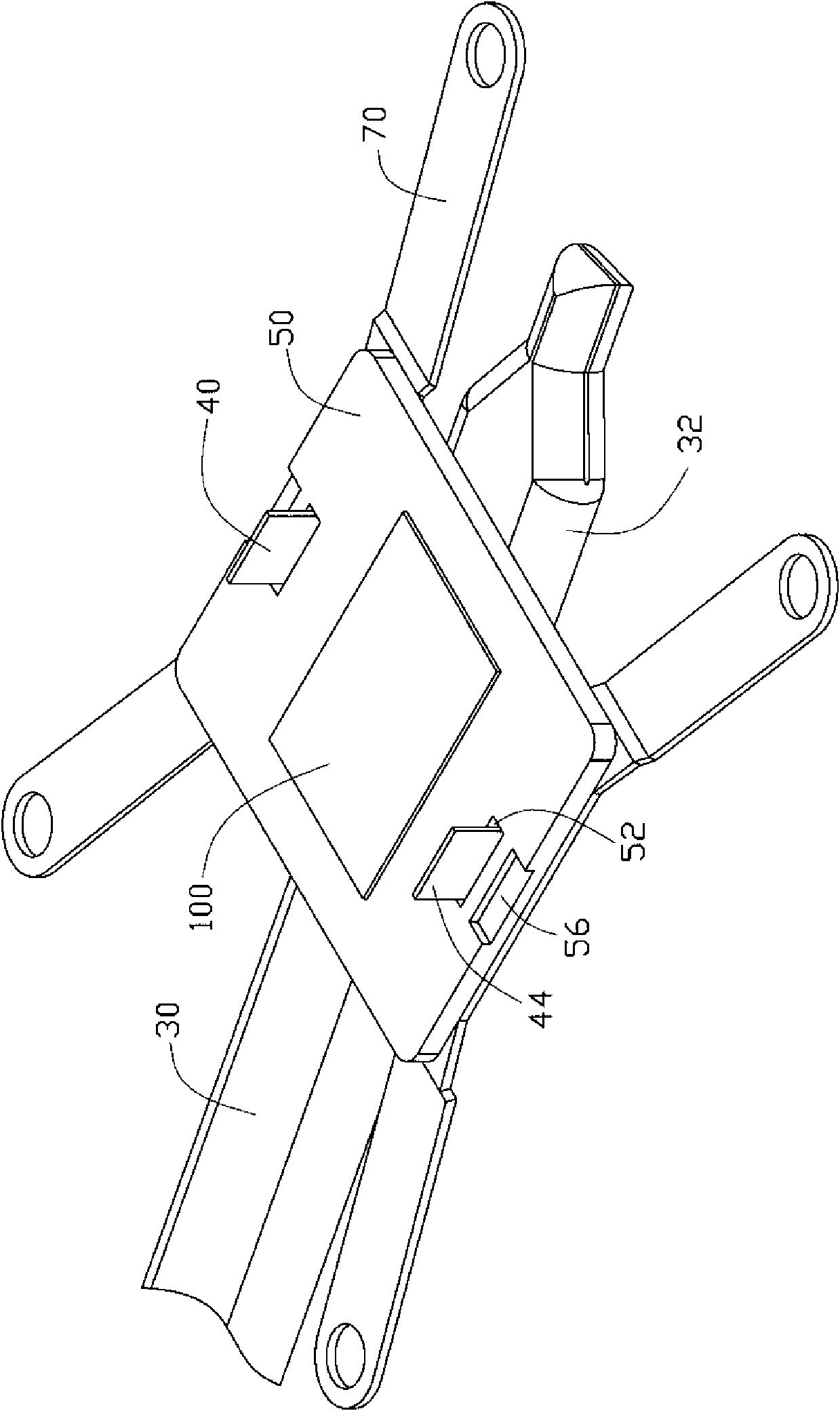

[0016] see Figure 1 to Figure 3 , the heat dissipation device of the present invention is used to dissipate heat from an electronic component 100 mounted on a circuit board (not shown), and it includes a radiator 10, a centrifugal fan 20 positioned at one side of the radiator 10, and the radiator A heat pipe 30 thermally connected to the device 10 , a base plate 50 thermally coupled with the free end of the heat pipe 30 , and a buckle 40 for buckling and fixing the heat pipe 30 on the base plate 50 . The heat dissipation device also includes two elastic pieces 70 placed on the substrate 50 for fixing the substrate 50 to the circuit board.

[0017] The heat sink 10 includes several heat dissipation fins combined with each other. The cooling fins are parallel to each other and arranged vertically. An air flow channel is formed between every two adjacent heat dissipation fins. A gap is formed in the middle of each cooling fin, and these gaps are connected to form a strip-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com