Method for forecasting sharp drop of pressure of melter-gasifier and method for controlling the pressure in ironmaking process

A melter-gasifier, a sharp drop technology, applied in steel manufacturing process, furnace control device, furnace monitoring device, etc. Eliminate problems such as unstable operation of the gasifier, and achieve the effect of improving operational productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

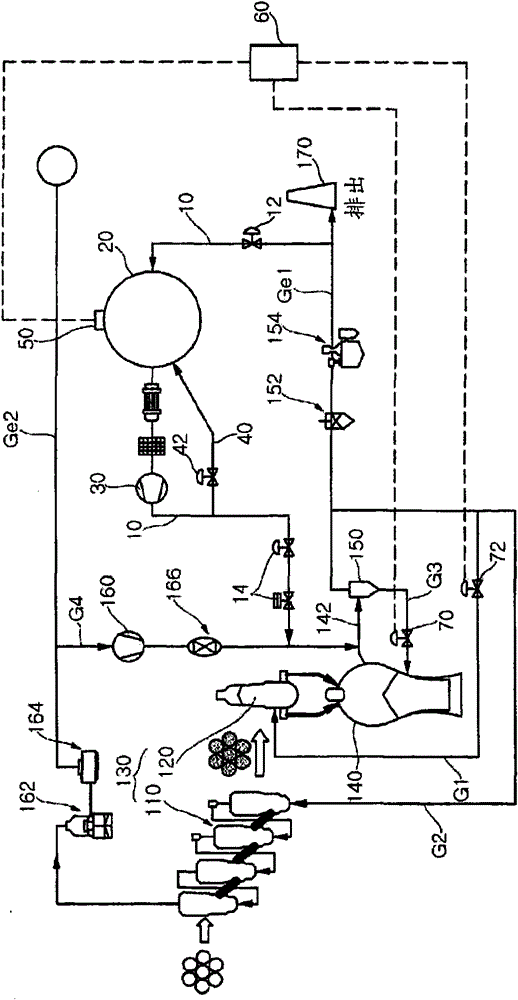

[0032] Reference will now be made in detail to the embodiments of the present disclosure, examples of which are illustrated in the accompanying drawings.

[0033] under the Figure 1 to Figure 3 In , the reference numerals of the components related to the iron-making process are shown in the 100 series, and the reference numerals of the components related to the excess gas recovery system according to the present invention are shown in the 10 series. The gas circulation line and the excess gas line are the main lines in the gas circulation system, their initials are shown with the letter "G", and the numbers are used to distinguish them.

[0034] figure 1 is a flowchart of an excess gas circulation system in the FINEX process, which is a typical process for producing molten iron by directly using non-coking coal and fine iron ore.

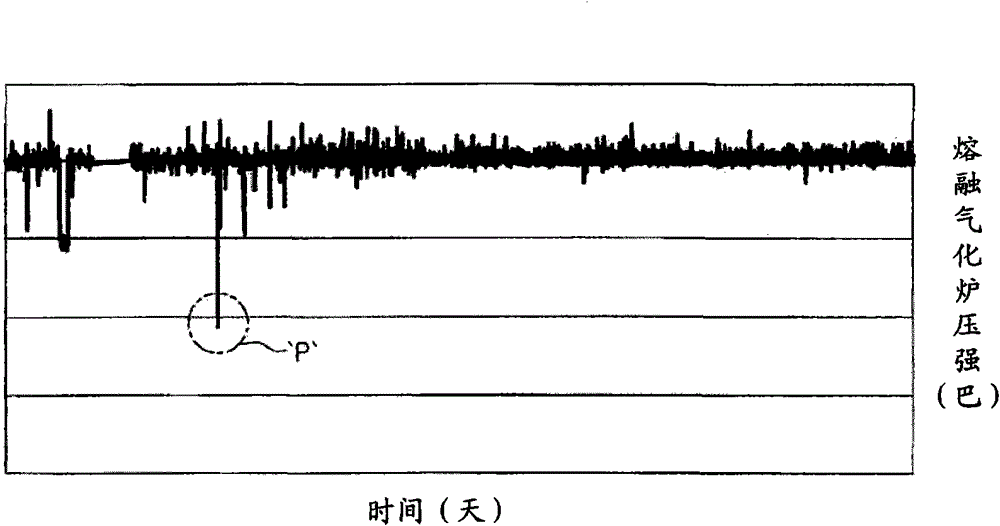

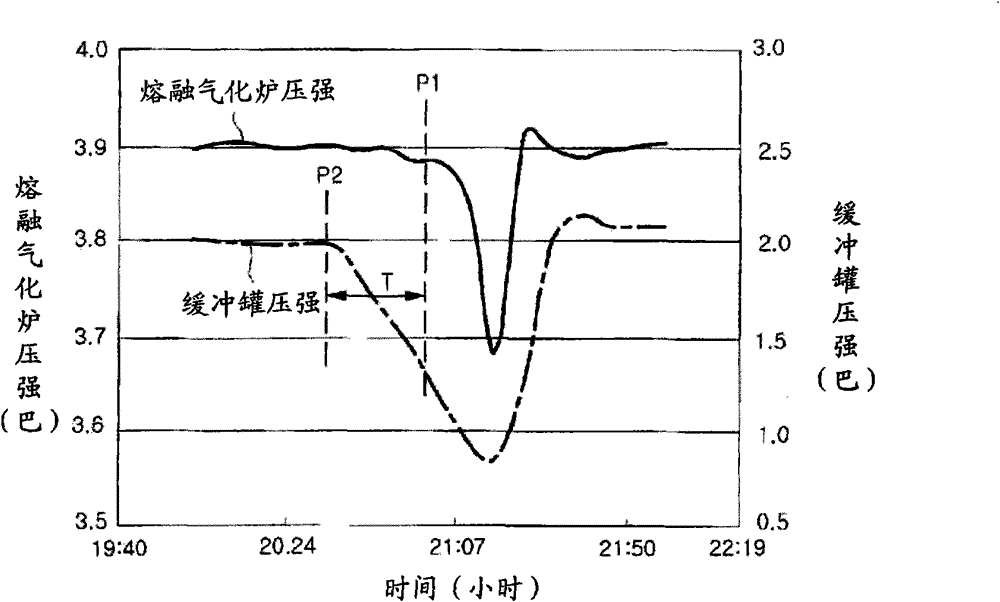

[0035] Before describing a method for predicting a sharp pressure drop in a melter-gasifier and a method for controlling the pressure, an exces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com