Crystal block slicing method

A technology for slicing and ingots, which is applied to fine working devices, stone processing equipment, manufacturing tools, etc., can solve problems such as steel wire slippage, high ratio, and reduced slicing yield, and achieve the quality of silicon wafers Effects of improvement, line mark reduction, and yield assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

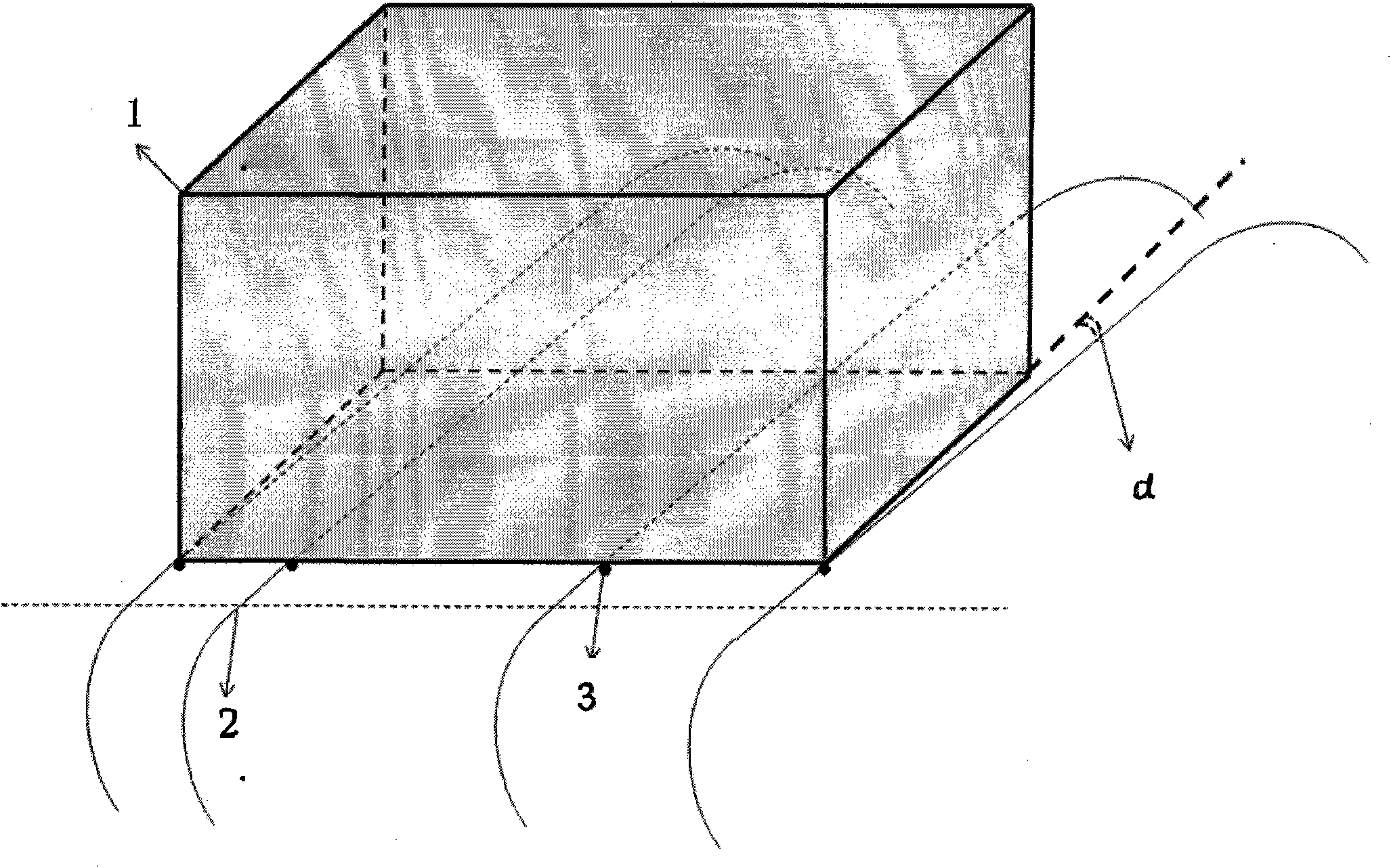

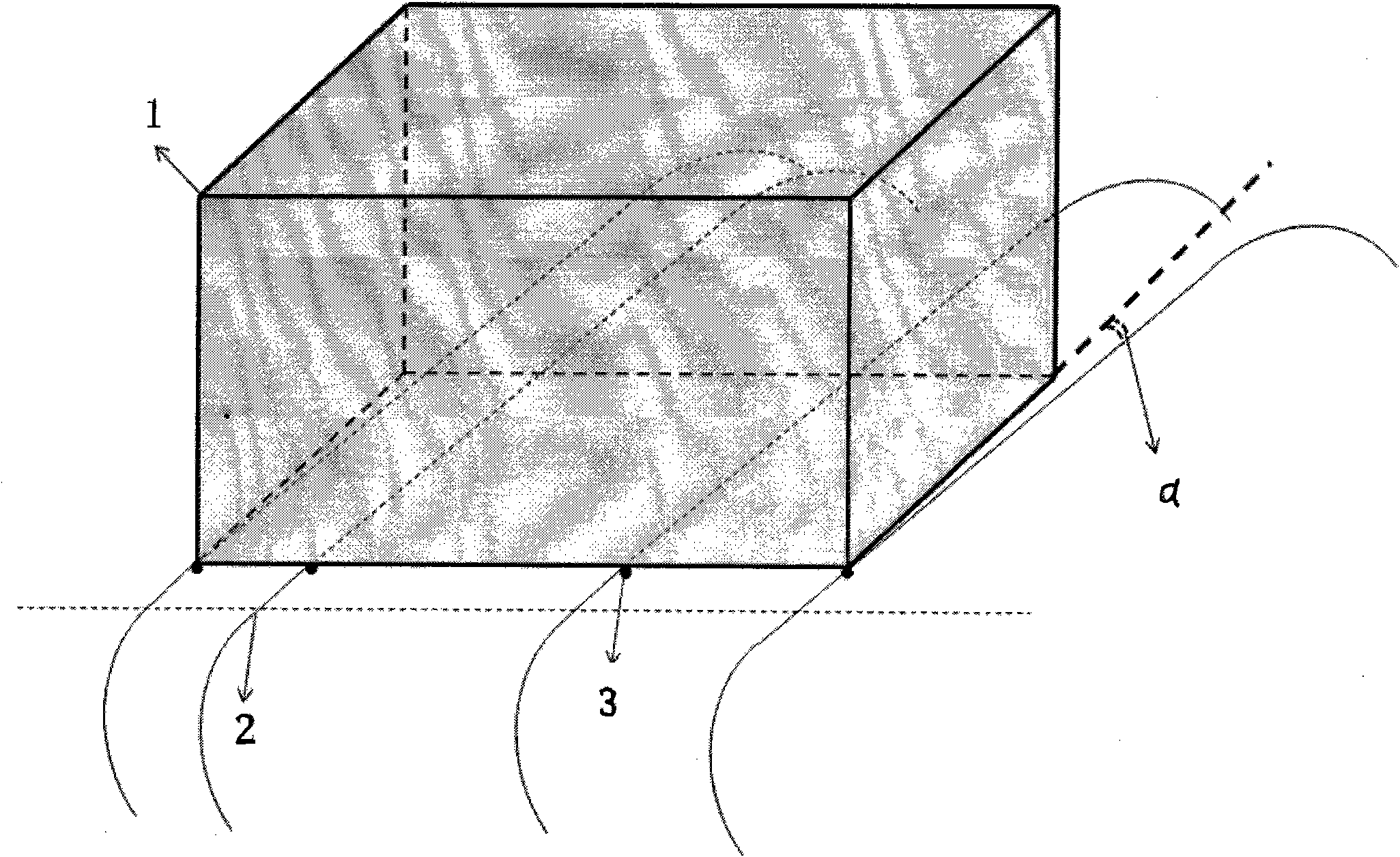

[0013] Such as figure 1 As shown, a crystal block slicing method, the silicon block 1 to be sliced is placed in a slicer, the cutting surface of the silicon block 1 to be sliced and the slicing wire mesh form a certain angle α, when the slicing wire mesh is cut , the steel wire 2 in the slicing wire network is in point contact with the side edge of the cut surface of the silicon block 1, and the black dot in the figure shows the contact point 3.

[0014] The production method is as follows:

[0015] (1) Carry out prescribing, testing, truncation, chamfering, grinding and other processes on polycrystalline ingots to make finished polycrystalline ingots; for single crystal ingots, truncation, testing, edge cutting, truncation, chamfering, Grinding and other processes to make finished single crystal ingots;

[0016] (2) Clean the finished crystal blocks and auxiliary materials such as glass plates in an ultrasonic tank covered with a soft rubber pad and filled with an appro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com