Metal container with locking member

A technology for metal containers and parts, which is applied in the field of manufacturing process of forming the outer upper end of the locked parts, which can solve the problems of crack penetration and increase the assembly process, etc., and achieve the effects of reduced manufacturing unit price, improved production efficiency, and good airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following is a preferred implementation example of the present invention, and the metal container with locking parts of the present invention will be further described with reference to the accompanying drawings:

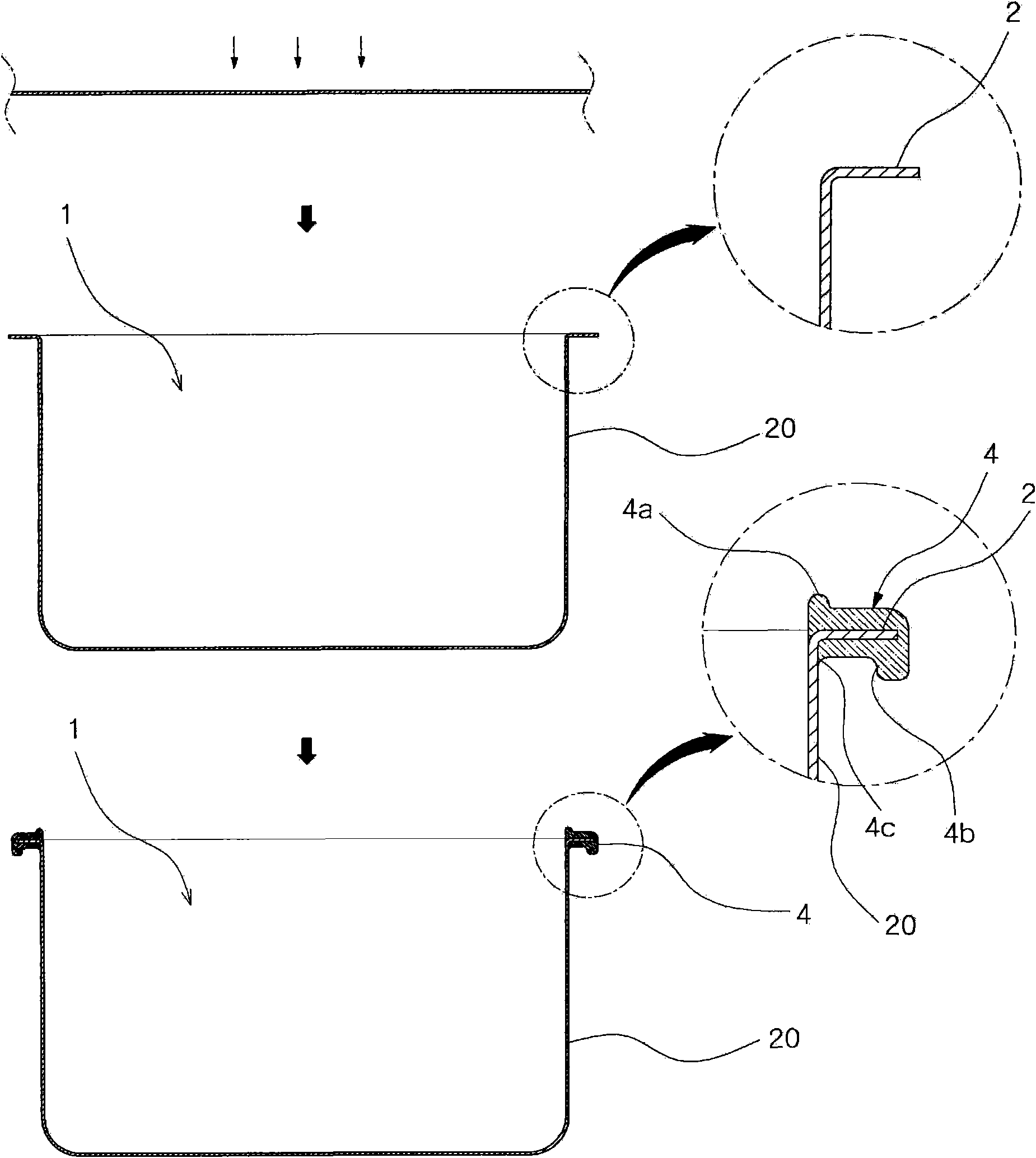

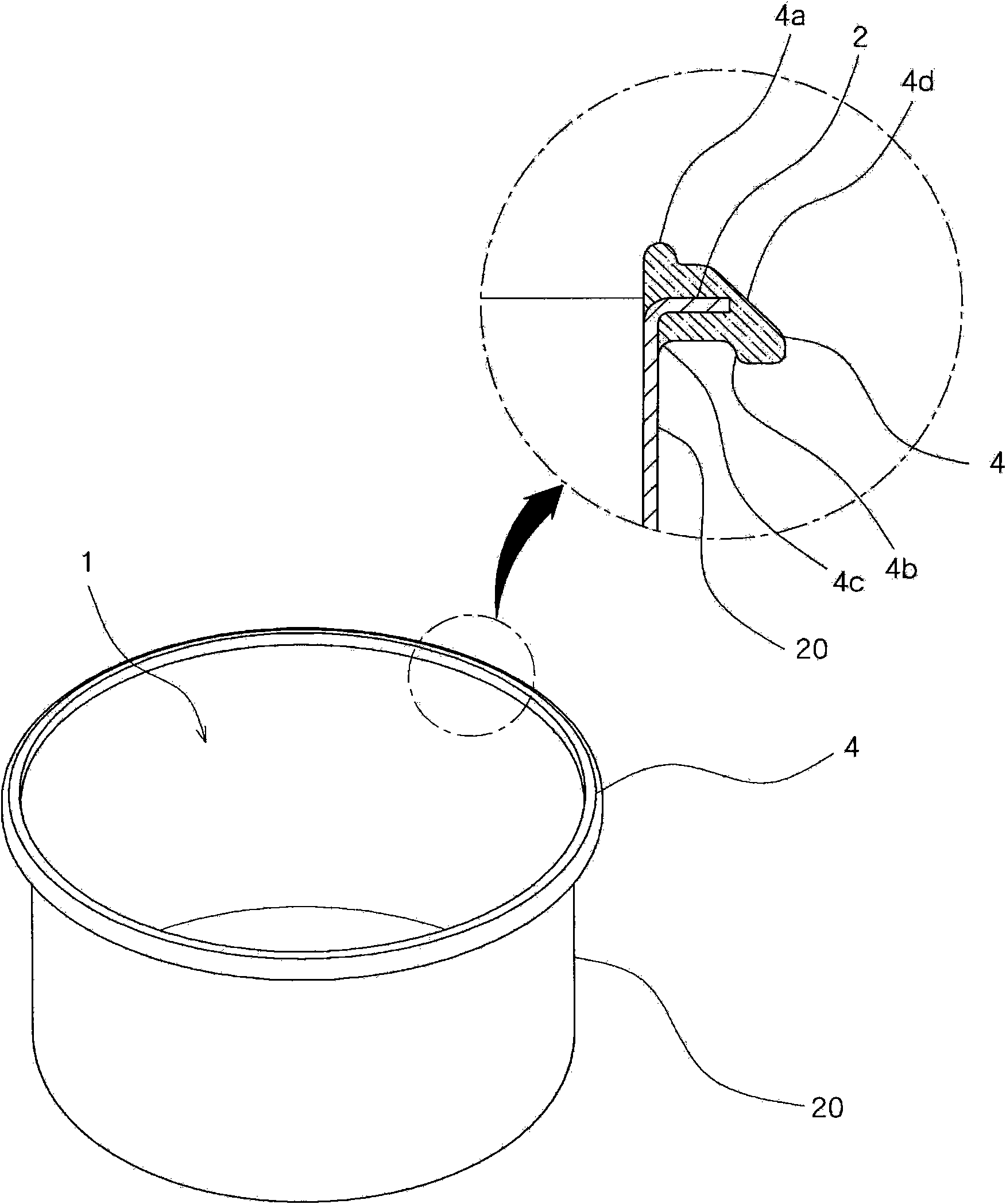

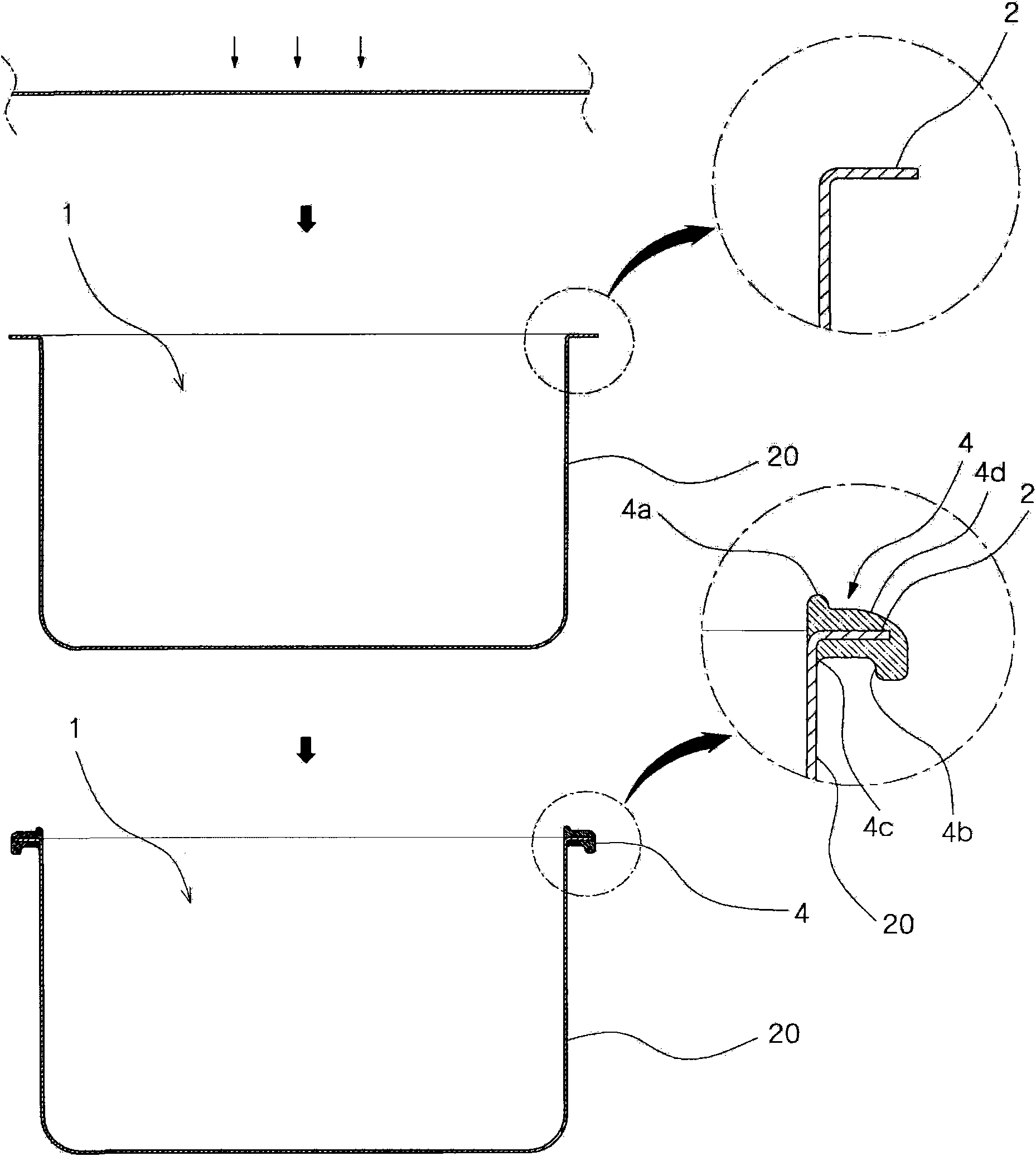

[0030] Such as figure 1 , Figure 1a and Figure 1b As shown, the metal container of the present invention forms the inner space 1 in the center through the metal plate forging process, and after the upper side end of the inner space 1 is extended outward and horizontally bends to form the protruding edge 2, it is injected by embedding. The molding process forms the locking part 4, and the locking part 4 wraps the upper and lower outer sides of the above-mentioned protruding edge part 2, and the whole container 20 is formed into one body, so that the locking part 4 is avoided on the protruding edge part 2. An arbitrary separation occurs.

[0031] At this time, the lock member 4 in the present invention is constituted as follows: Figure 9 As shown, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com