Method for extracting blueberry anthocyanin

A technology of blueberry anthocyanin and extraction method, which is applied in the field of blueberry anthocyanin extraction, can solve the problems of blueberry fruit rot economic loss, strong seasonal blueberry fruit harvesting, environmental pollution, etc., and achieves convenient large-scale production and low cost Low, environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

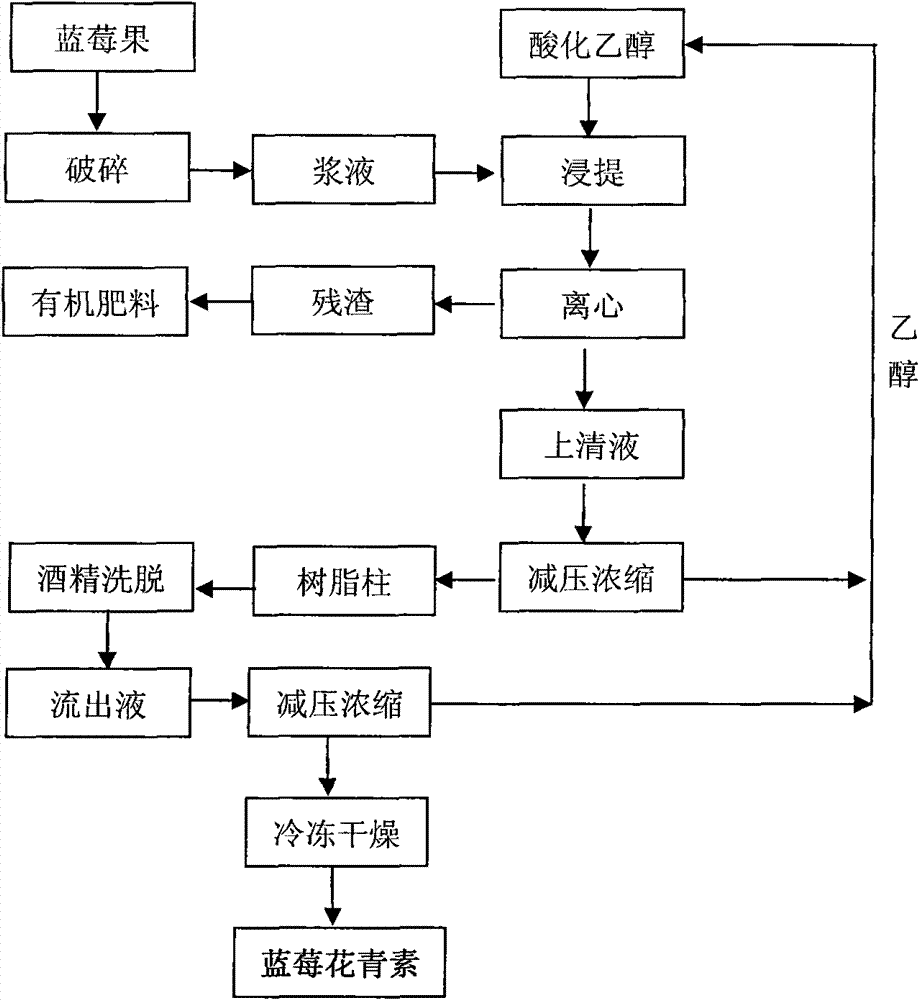

[0021] see figure 1 A method for extracting blueberry anthocyanins comprises the following steps:

[0022] Step 1: Pretreatment of raw materials: Take 10g of blueberries that are free of rot, washed and removed, add 10mL of ethanol solution acidified with citric acid, put them into an electric homogenizer to crush and beat, and obtain blueberry slurry;

[0023] The volume fraction of ethanol in the ethanol solution acidified with citric acid is 45%, and citric acid is added dropwise to make the ethanol solution acidified with citric acid have a pH value of 5.0.

[0024] Step 2: Extraction of blueberry anthocyanins: take the blueberry slurry, add 55mL of ethanol solution acidified with citric acid (pH5.0, ethanol volume fraction is 45%) according to the volume ratio of solid to liquid 1:6, first ultrasonically assist the extraction, then ultrasonically The auxiliary extraction conditions are ultrasonic temperature 40°C, ultrasonic power 500W, duty ratio 1:0.1, ultrasonic time ...

Embodiment 2

[0027] A method for extracting blueberry anthocyanins comprises the following steps:

[0028] Step 1: Pretreatment of raw materials: take 10g of frozen blueberries, wash them and grind them thoroughly with a mortar to obtain blueberry slurry;

[0029] Step 2: Extraction of blueberry anthocyanins: take blueberry slurry, add 70mL of ethanol solution acidified with tartaric acid according to the volume ratio of material to liquid 1:4, and first ultrasonically assist the extraction. The ultrasonic extraction conditions are ultrasonic temperature 30°C, ultrasonic power 700W, Duty ratio 1:0.3, ultrasonic time 10min, and then leached at 55°C for 2 hours to obtain the extract; take the extract and centrifuge at 9000r / min for 10min to obtain the precipitate and supernatant, and the precipitate was subjected to the above conditions Leach once more, and collect the supernatant by centrifugation under the same conditions as above; collect and combine the clarified centrifugal supernatants...

Embodiment 3

[0033] A method for extracting blueberry anthocyanins comprises the following steps:

[0034] Step 1: Pretreatment of raw materials: Take 100g of blueberries that are free of rot, washed and removed, add 150mL of ethanol solution acidified with lactic acid, put them into an electric homogenizer to crush and beat, and obtain blueberry slurry;

[0035] The volume fraction of ethanol in the ethanol solution acidified by lactic acid is 65%, and lactic acid is added dropwise to make the ethanol solution acidified by lactic acid have a pH of 6.0.

[0036] Step 2: Extraction of blueberry anthocyanins: take blueberry slurry, add 650mL of lactic acid acidified ethanol solution (pH6.0, ethanol volume fraction is 65%) according to the volume ratio of material to liquid of 1:10, first ultrasonically assisted extraction, ultrasonically assisted The extraction conditions are ultrasonic temperature 50°C, ultrasonic power 600W, duty ratio 1:0.5, ultrasonic time 5min, and leaching at 65°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com