Light guide member, planar light source device using the light guide member, and display apparatus

A technology of light guide components and planar light sources, which is applied in the direction of optical components, light guides, lighting devices, etc., can solve the problems of increased backlight thickness, and achieve the effects of preventing obvious gaps, promoting uniformity, and high image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] Hereinafter, a light guide member, a planar light source device using the same, and a display device relating to the present invention will be described in detail with reference to the accompanying drawings. The present invention is not limited to the following examples.

[0074] In the description of the embodiments of the present invention, for the convenience of explanation, "upward" refers to the direction from the light source (solid-state light emitting device) to the light guide element.

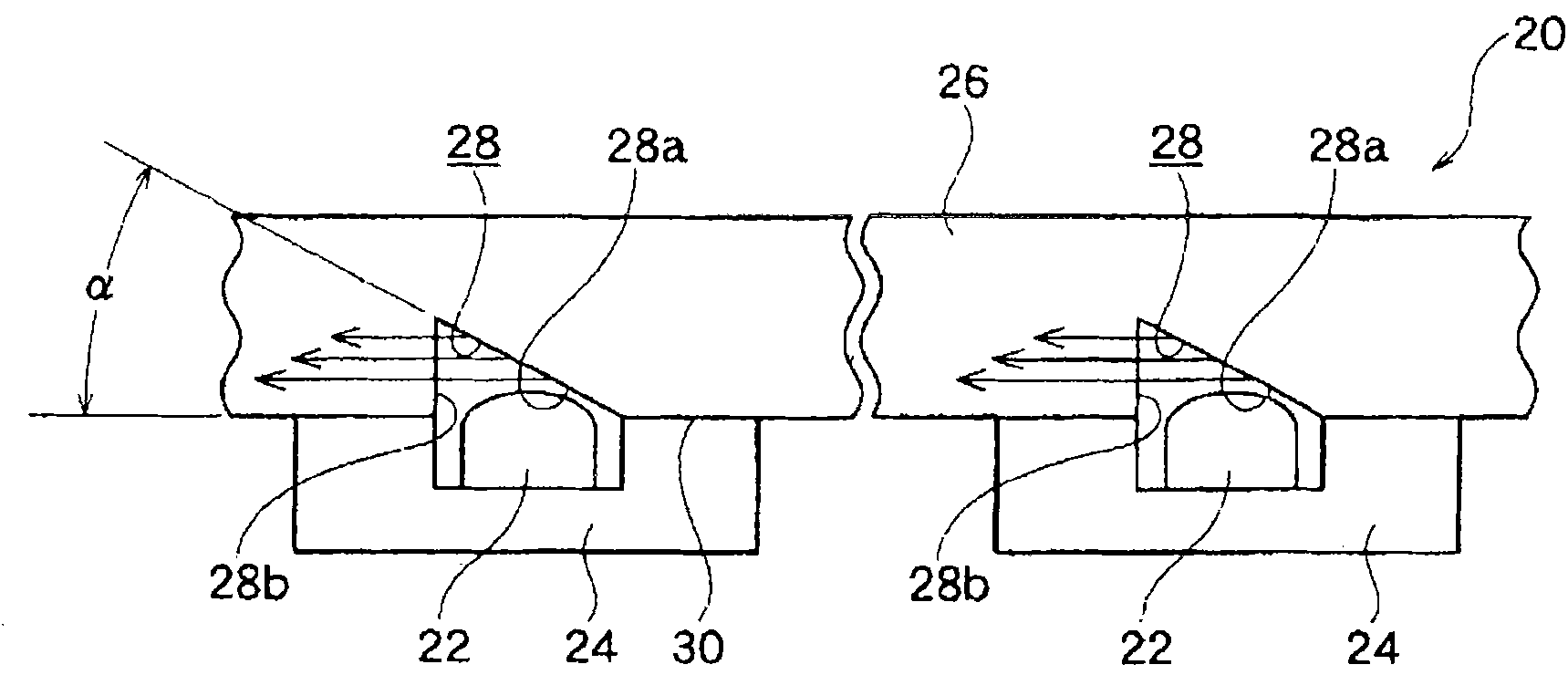

[0075] It is effective to employ a light guide member to sufficiently realize uniformity of luminance and chromaticity and to prevent increase in thickness of a planar light source device for a so-called direct-illumination type backlight. Since the solid state light emitting device is mounted upward for a direct lit backlight, diffuse and evenly spread light is preferred in the light guide element.

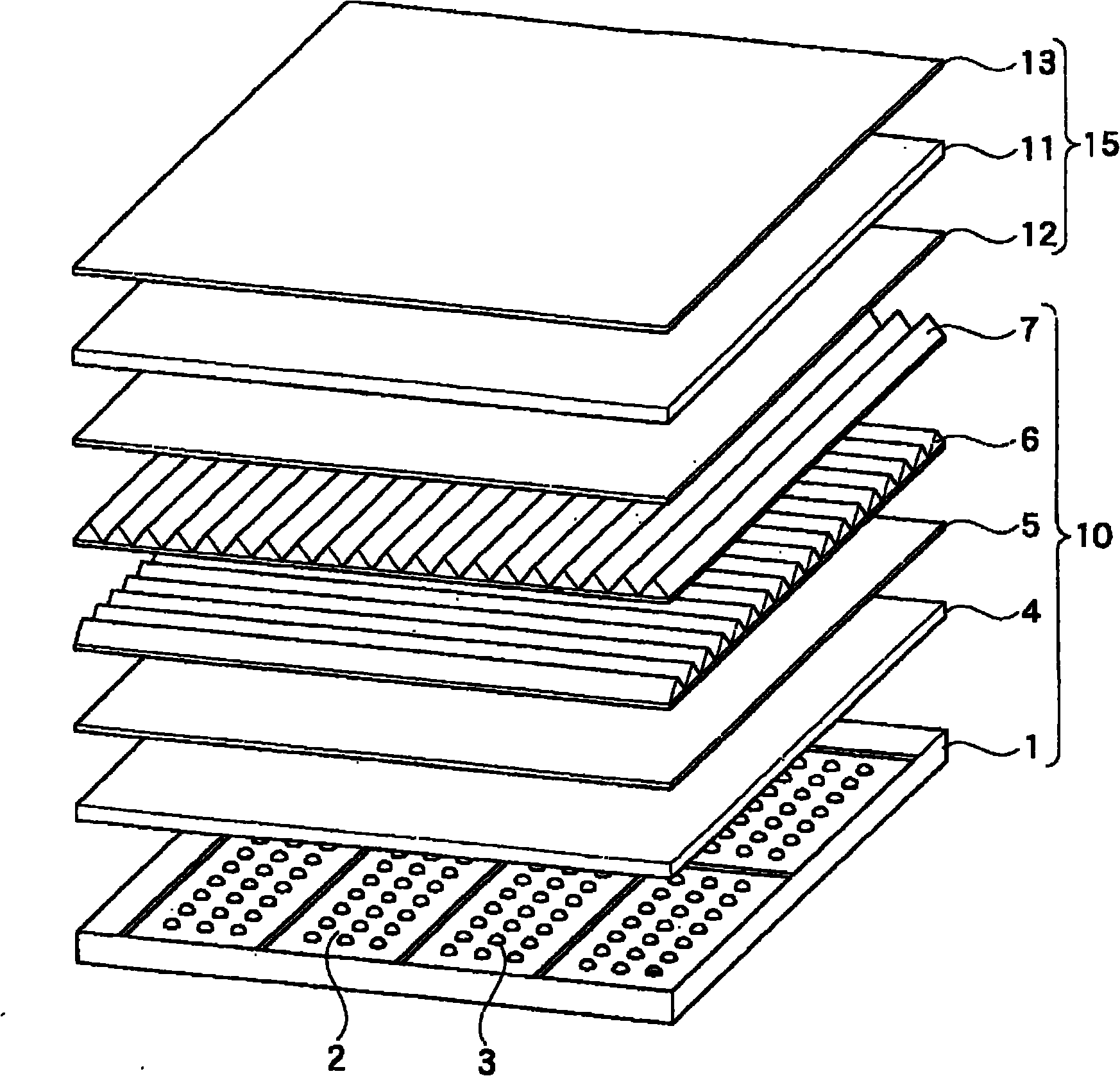

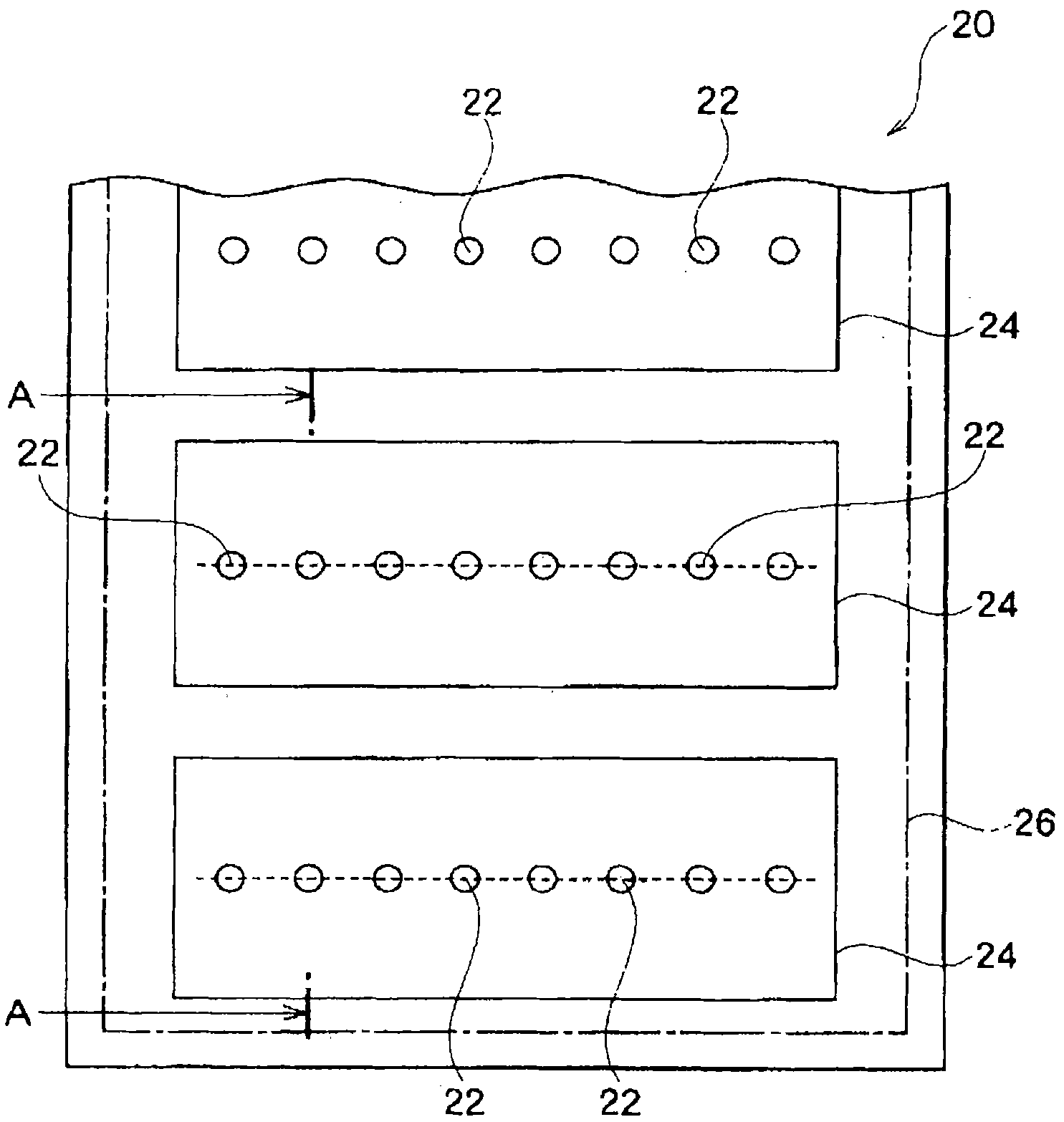

[0076] figure 1 is a view for showing the entire structure of an example o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com