Novel energy-saving refrigerating unit and working method thereof

A refrigerating unit and working method technology, applied in the direction of refrigerating machines, refrigerating components, refrigeration and liquefaction, etc., can solve the problems of reduced total liquid reaching the evaporator, insignificant energy saving effect, increased unit cost, etc., and achieve liquid supercooling Large, low-cost, simple-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

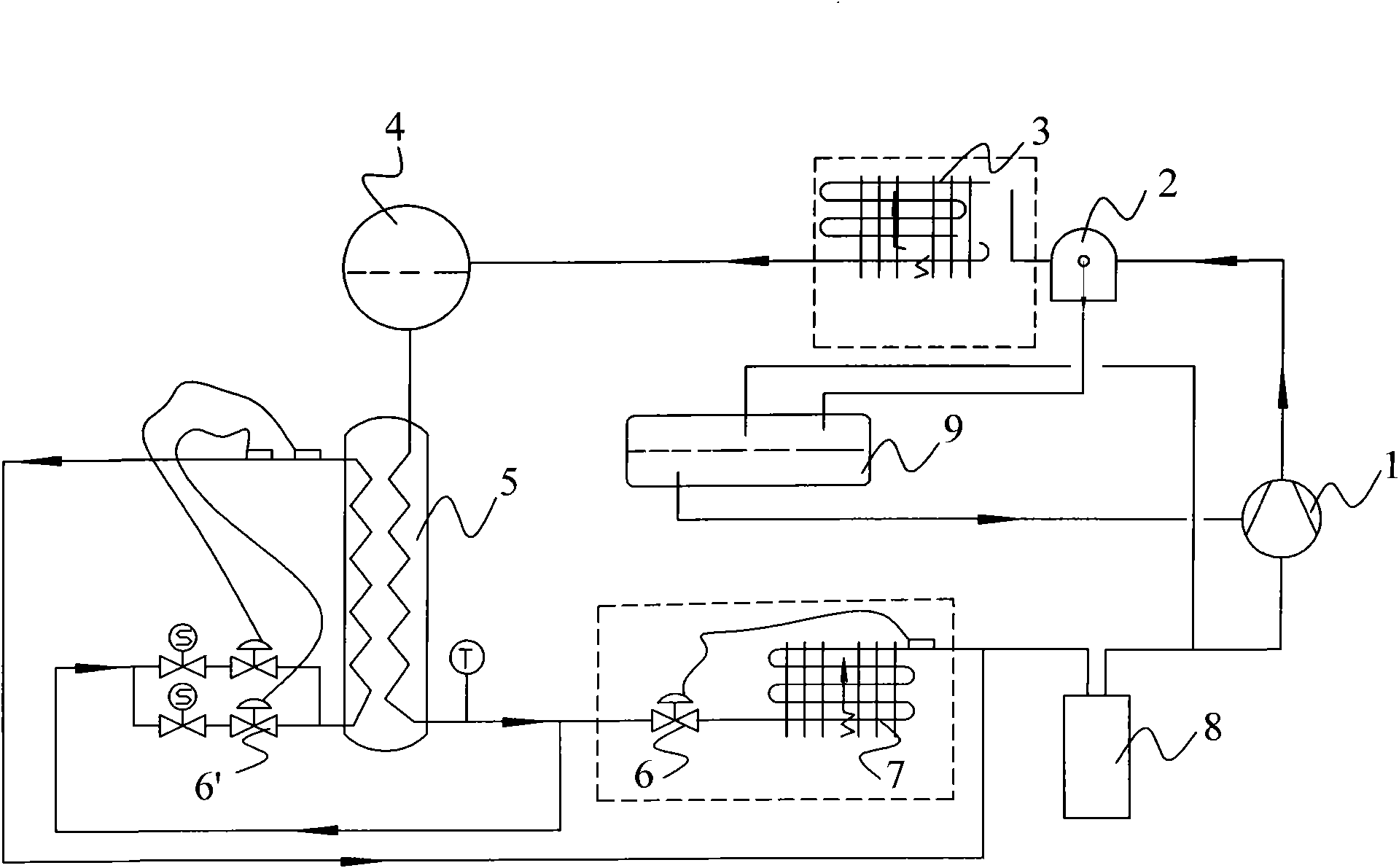

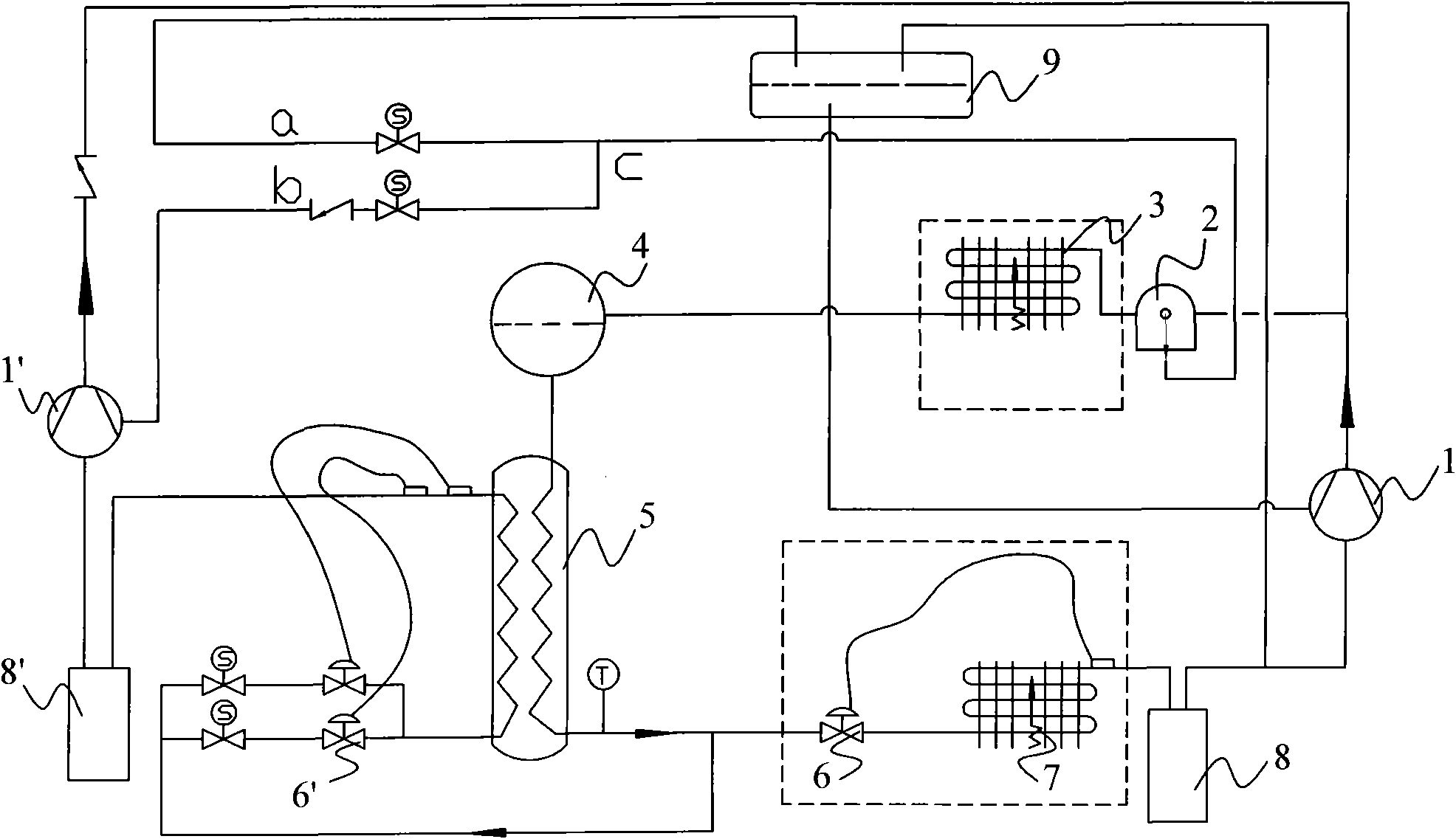

[0013] Such as figure 2 The new energy-saving refrigeration unit shown in the figure is connected by the outlet of the liquid receiver 4 to the inlet of the cooled end of the heat exchanger 5. The heat exchanger 5 is divided into two circuits by the outlet pipeline of the cooling terminal, and one pipeline passes through the medium temperature expansion valve. 6' and connected to the inlet of the low-pressure end of the heat exchanger 5, and the other path is connected to the low-temperature evaporator 7 through the low-temperature expansion valve 6, and the low-temperature evaporator 7 is connected to the gas-liquid separator 8. After being separated by the gas-liquid separator 8 Refrigerant gas enters the low-temperature compressor 1; the exhaust refrigerant outlet of the heat exchanger 5 is connected to the medium-temperature compressor 1' after passing through the medium-temperature gas-liquid separator 8', and the medium-temperature compressor 1' The exhaust pipe of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com