Preparing and molding method for concrete in-situ direct shear test specimens

A technology of sample preparation and molding method, which is applied in the preparation of test samples, the use of stable shear force to test the strength of materials, sampling devices, etc., to reduce disturbance, improve cutting ability and labor productivity, and accurate sample size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

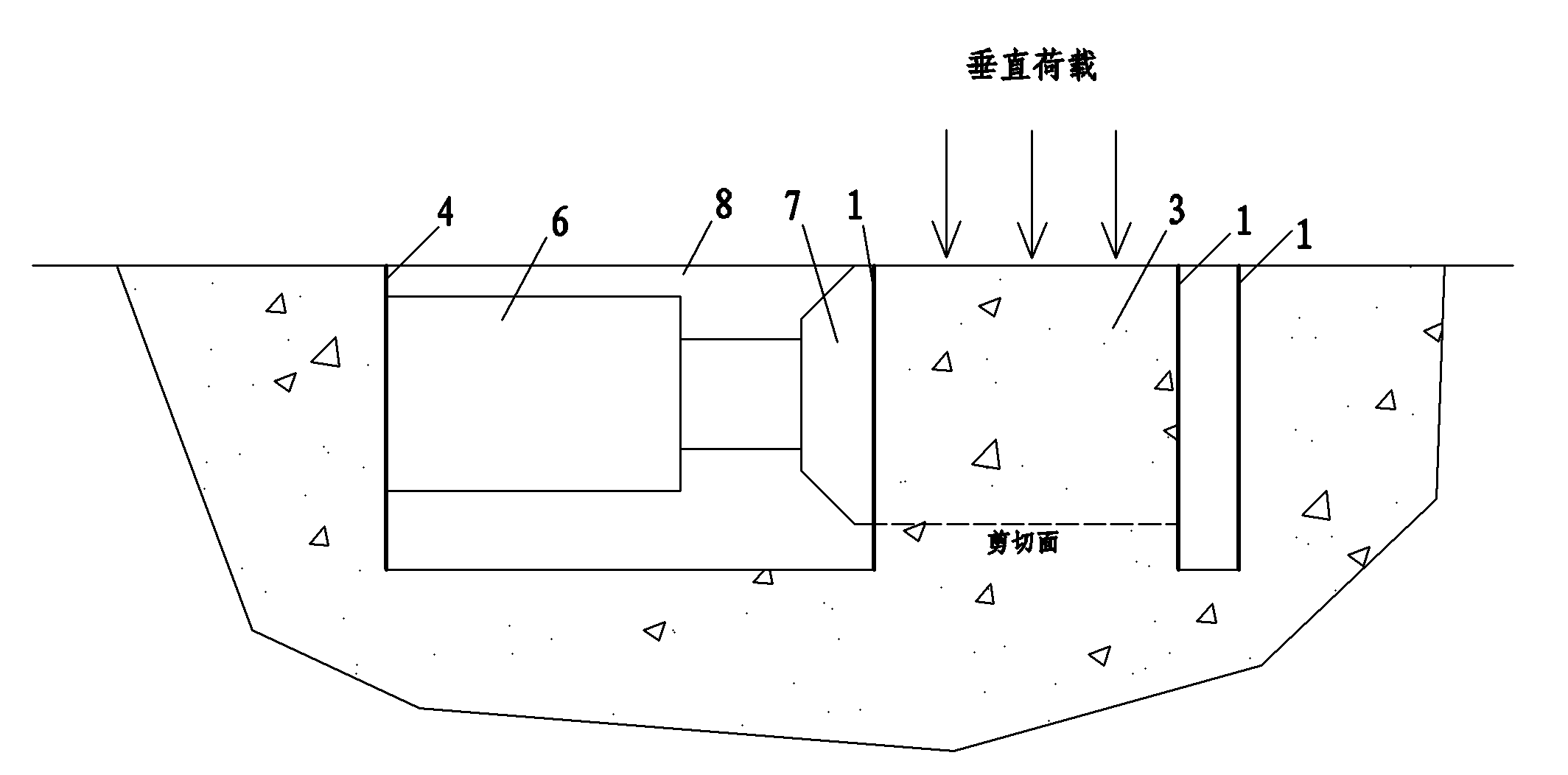

[0021] A method for preparing a concrete in-situ direct shear test sample, comprising the following steps:

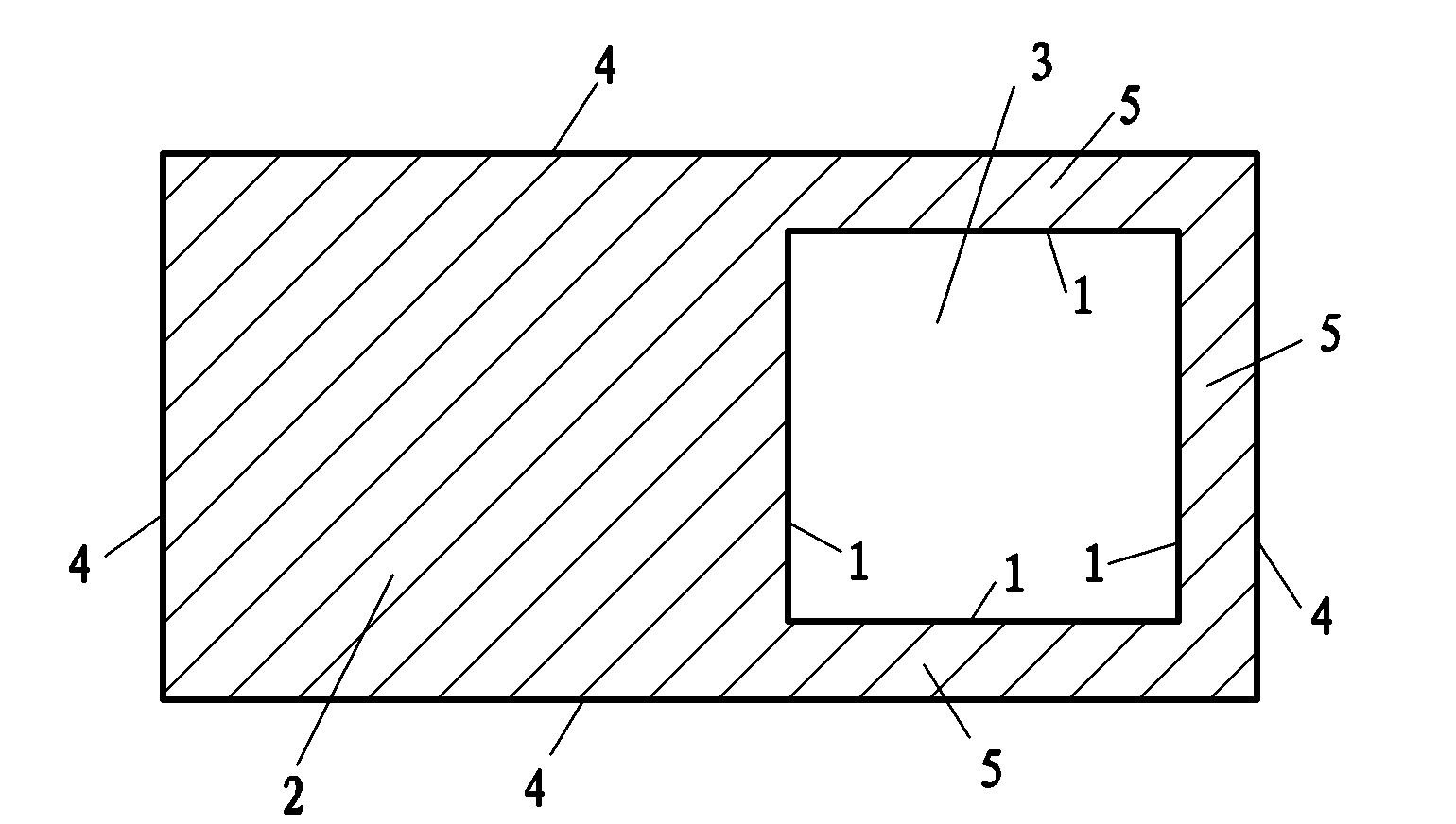

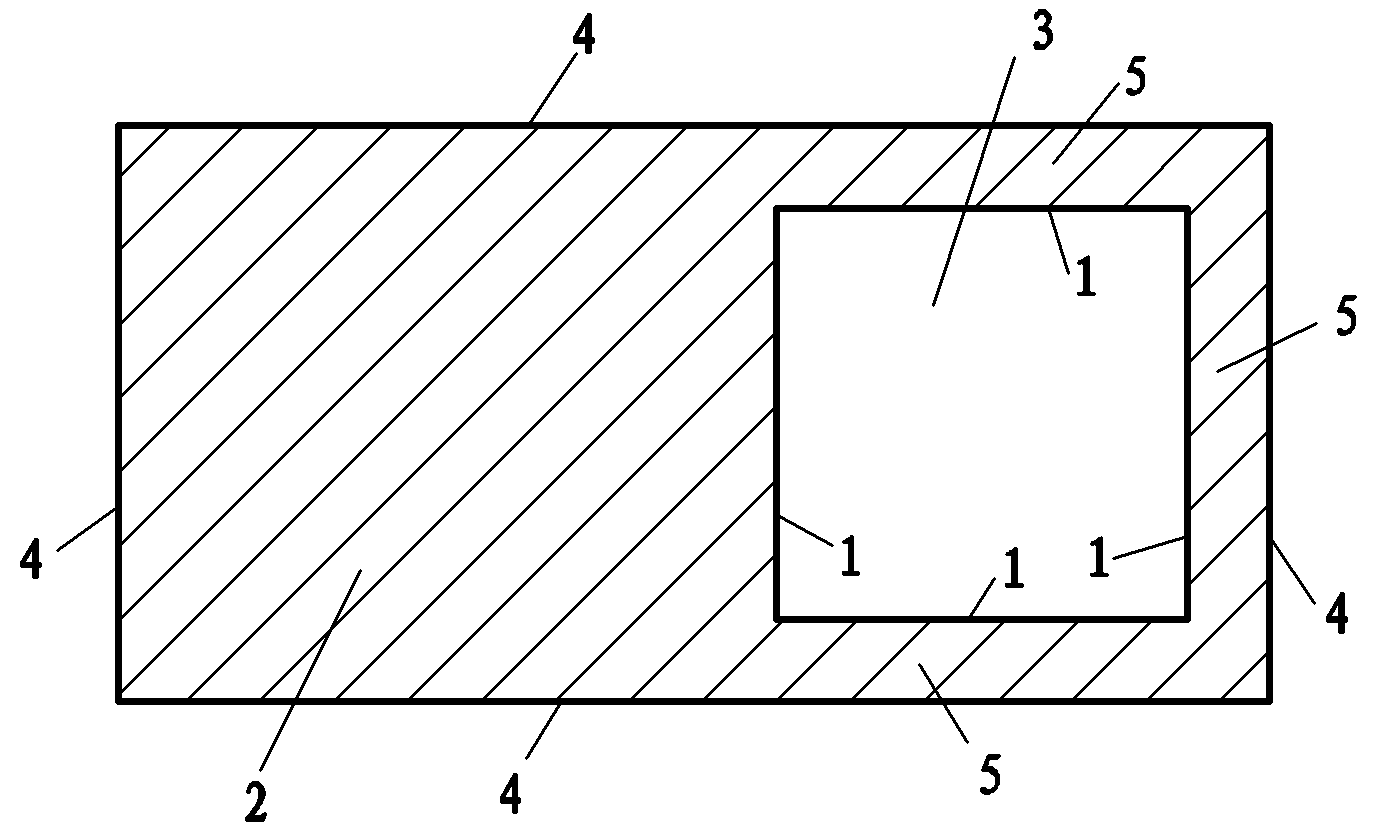

[0022] a. On-site stakeout, stake out at the test site according to the technical requirements, mark the size of the sample 3, and determine the position of the cutting line according to the technical parameters. The cutting line consists of the contour line 1 of the four sides of the sample and the sample corresponding to the contour line 1 The outer contour line 4 of the peripheral concrete consists of four contour lines 1 and four corresponding outer contour lines 4;

[0023] Among the contour lines 1 of the four sides of the sample, a certain gap is guaranteed between the contour lines 1 of three sides and their corresponding outer contour lines 4 to form a shear seam 5, and the gap between the contour line 1 of the other side and its corresponding outer contour line 4 is due to It is necessary to install the shear loading jack 6, and there must be a relatively larg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com