In-massif large scale pressure test equipment and test method thereof

A pressure test and testing device technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of low cost, easy deformation and fatigue of steel, and high cost, achieve accurate and stable data, save experimental costs, The effect of the small loss of the mountain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

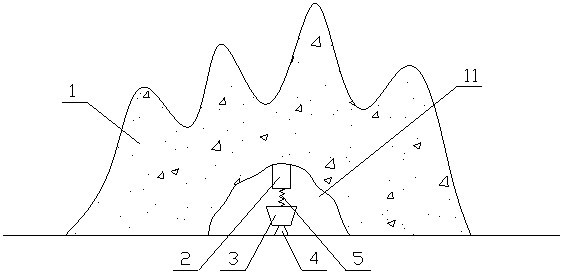

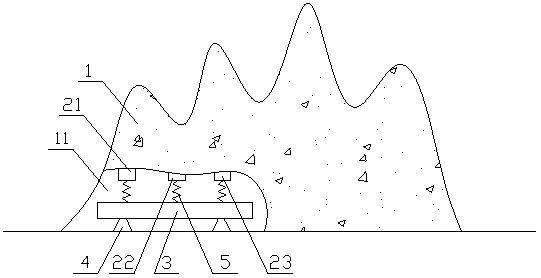

[0028] Large-scale pressure test equipment in the mountain, such as Figure 1 to Figure 2 As shown, the large-scale pressure testing equipment in the mountain includes the pressure unit 2, the test device 5 and the base 4, and also includes the cave 11. The cave 11 is set in the mountain 1, and the pressure unit 2, the test device 5 and the base 4 are set in the cave. Inside the cave 11 , the test material 3 is set on the base 4 , and the press unit 2 includes at least one press machine 21 , 22 , 23 set on the top of the cave 11 . The pressure test equipment is installed in the cave 11 of the mountain body 1, so on the one hand the test material 3 is not limited by the steel girder gantry, and on the other hand, the test material 3 can be deployed and transported well by using the open space in front of the cave 11. Very beneficial for testing with large materials.

[0029] The mountain body 1 is a continuous whole mountain body. The use of a continuous and integral mountain...

Embodiment 2

[0043] Large-scale pressure test equipment in the mountain, such as Figure 1 to Figure 2 As shown, it includes a pressure unit 2, a test device 5 and a base 4, and also includes a cave 11, the cave 11 is arranged in the mountain body 1, the pressure unit 2, the test device 5 and the base 4 are arranged in the cave 11, and the test material 3 is arranged On the base 4 , the press unit 2 includes at least one press 21 , 22 , 23 arranged on the top of the cave 11 . The pressure test equipment is installed in the cave 11 of the mountain body 1, so on the one hand the test material 3 is not limited by the steel girder gantry, and on the other hand, the test material 3 can be deployed and transported well by using the open space in front of the cave 11. Very beneficial for testing with large materials.

[0044] The mountain body 1 is made of granite. The rocky geology of the mountain body 1 is chosen to be relatively hard materials such as granite, which is more beneficial to wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com