Simulation test method of road surface anti-skidding overlaying material unconsolidation and particle fall and testing equipment thereof

A simulation test, anti-skid technology, applied in the direction of material weighing, analyzing materials, measuring devices, etc., can solve problems such as limitations of test methods and methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1 (epoxy resin non-slip paving material):

[0049] The size of the test specimen 9 is 300mm long × 300mm wide × 50mm thick. The test specimen 9 is made of cement concrete with a thickness of 40mm as the bottom pavement panel, and a layer of non-slip surface material with a total thickness of about 10mm is laid on the surface. . The anti-skid overlay material surface layer is paved in two layers: the amount of epoxy adhesive for the first layer is 1.0L / m 2 , the dosage of basalt fine aggregate is 5.4kg / m 2 ; The dosage of the second layer of epoxy adhesive is 2.0L / m 2 , the dosage of basalt fine aggregate is 7.6kg / m 2 .

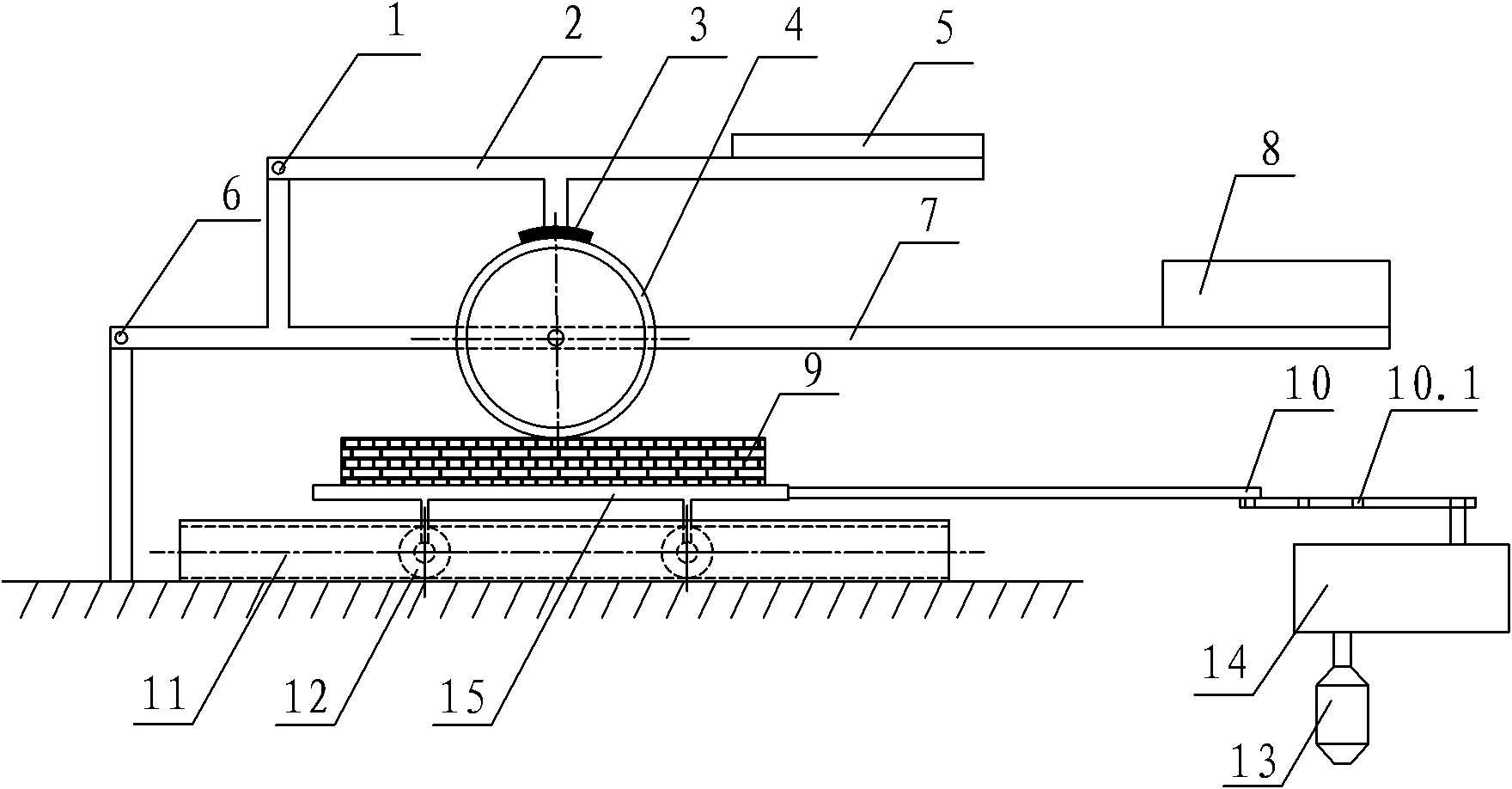

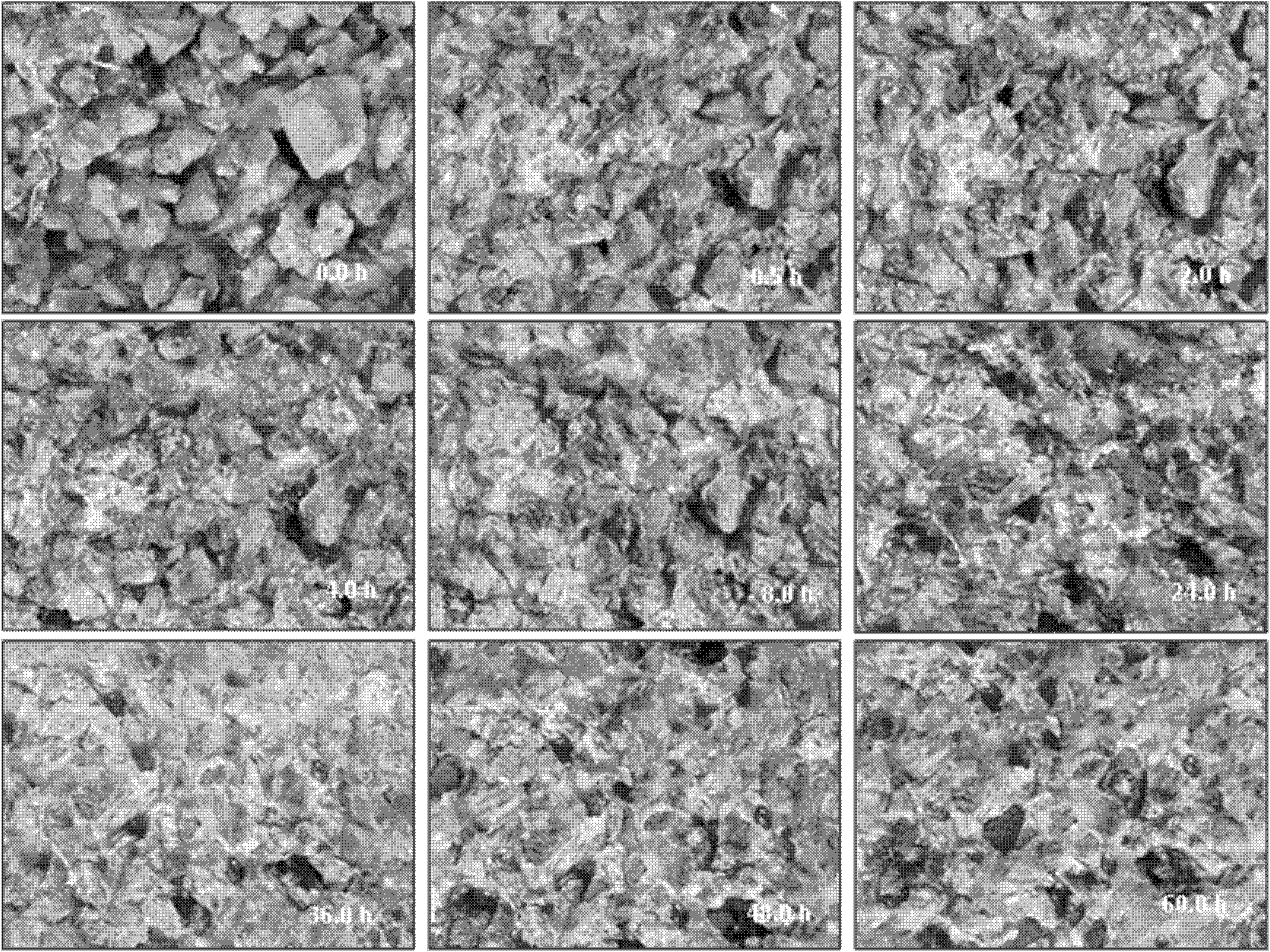

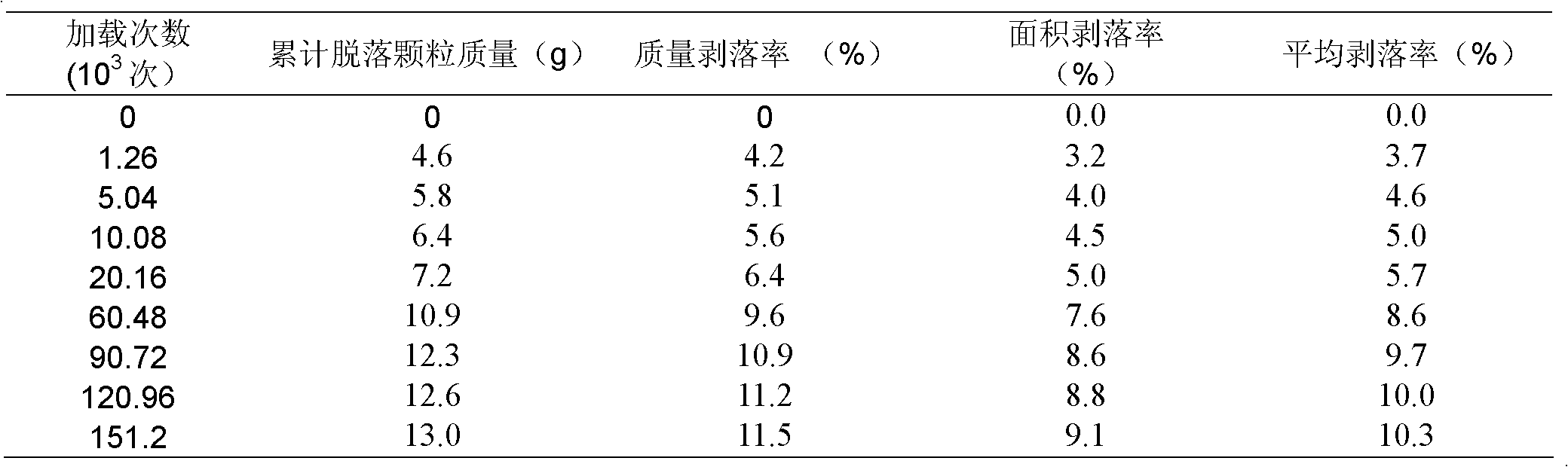

[0050] refer to figure 1 As shown in the schematic diagram of the simulation test equipment for the loosening of the anti-skid overlay material on the road surface, the test piece 9 is placed on the test platform 15, and the weight and position of the friction-adjustable counterweight 5 on the friction loading lever 2 are adjusted, and t...

Embodiment 2

[0052] Embodiment 2 (epoxy asphalt non-slip overlay material):

[0053] The size of the test piece 9 is 1000mm long x 300mm wide x 37mm thick. The test piece 9 is made of a 12mm thick steel plate as the bottom pavement panel, and a layer of anti-skid surface material with a total thickness of about 25mm is laid on the surface. The anti-slip overlay material surface layer is prepared from epoxy asphalt and basalt aggregates less than 9.5mm into fine epoxy asphalt mixture. Among them, the amount of epoxy asphalt is 6.3%.

[0054] refer to figure 1 As shown in the schematic diagram of the simulation test equipment for the loosening of the anti-skid overlay material on the road surface, the test piece 9 is placed on the test platform 15, and the weight and position of the friction-adjustable counterweight 5 on the friction loading lever 2 are adjusted, and the setting The friction force between the rubber friction plate 3 and the tire 4 is 1.0N per square millimeter. Adjust the...

Embodiment 3

[0056] Embodiment 3 (hot asphalt non-slip overlay):

[0057] The size of the test piece 9 is 500mm long x 300mm wide x 65mm thick. The test piece 9 is made of cement concrete with a thickness of 50mm as the bottom pavement panel, and a layer of non-slip surface material with a total thickness of about 15mm is laid on the surface. . The surface layer of anti-slip overlay material is prepared by hot asphalt and basalt aggregates less than 9.5mm. The surface layer is paved in two layers: the spraying amount of the first layer of hot asphalt is 0.6L / m 2 , the dosage of basalt fine aggregate is 2.0kg / m 2 ; The dosage of the second layer of epoxy adhesive is 0.4L / m 2 , the dosage of basalt fine aggregate is 1.6kg / m 2 .

[0058] refer to figure 1 As shown in the schematic diagram of the simulation test equipment for the loosening of the anti-skid overlay material on the road surface, the test piece 9 is placed on the test platform 15, and the weight and position of the friction-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Friction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com