Method for judging dewatering performance of different plasters

A dehydration performance and gypsum technology, applied in flow characteristics, instruments, analysis materials, etc., can solve the problems of long time-consuming constant weight, inability to predict slurry dehydration performance, increase in sewage cost, etc., to achieve fewer instruments, strong application value, The effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

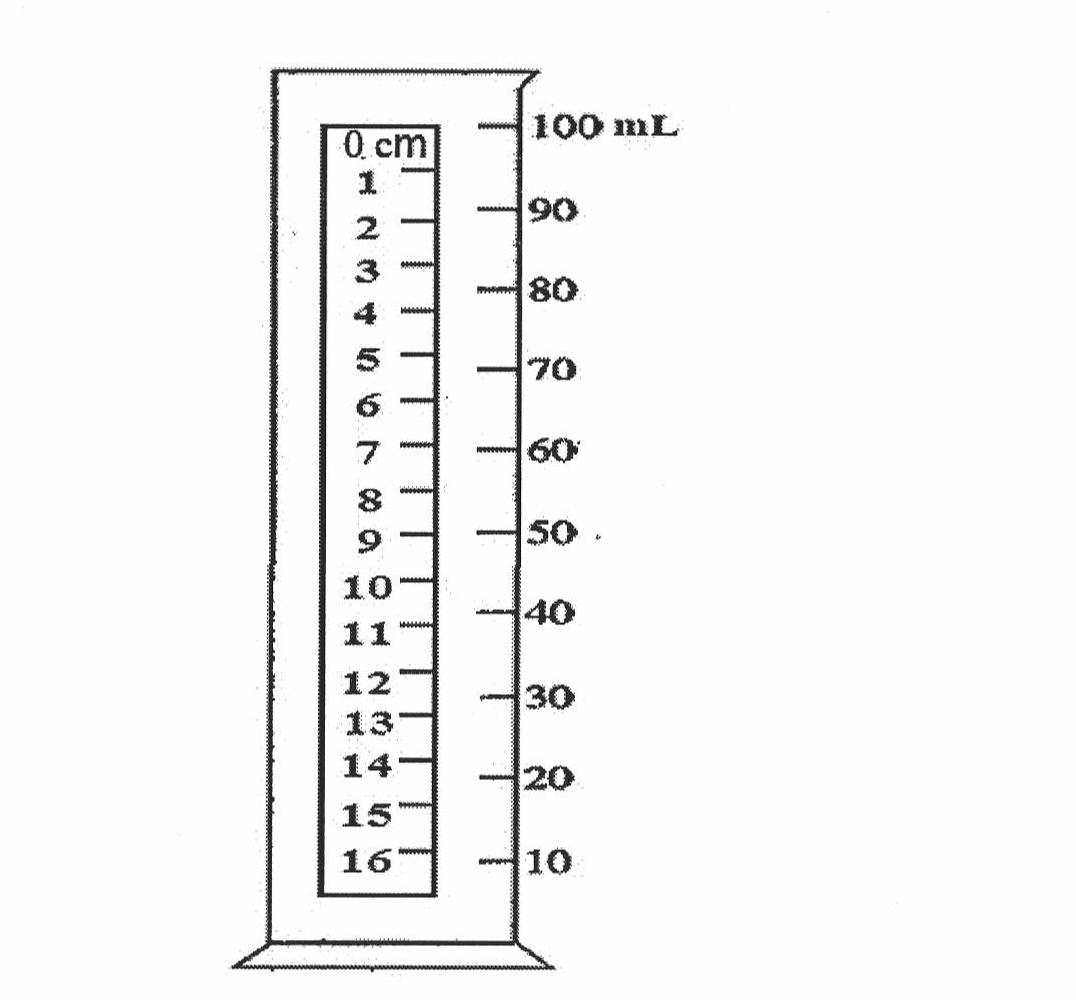

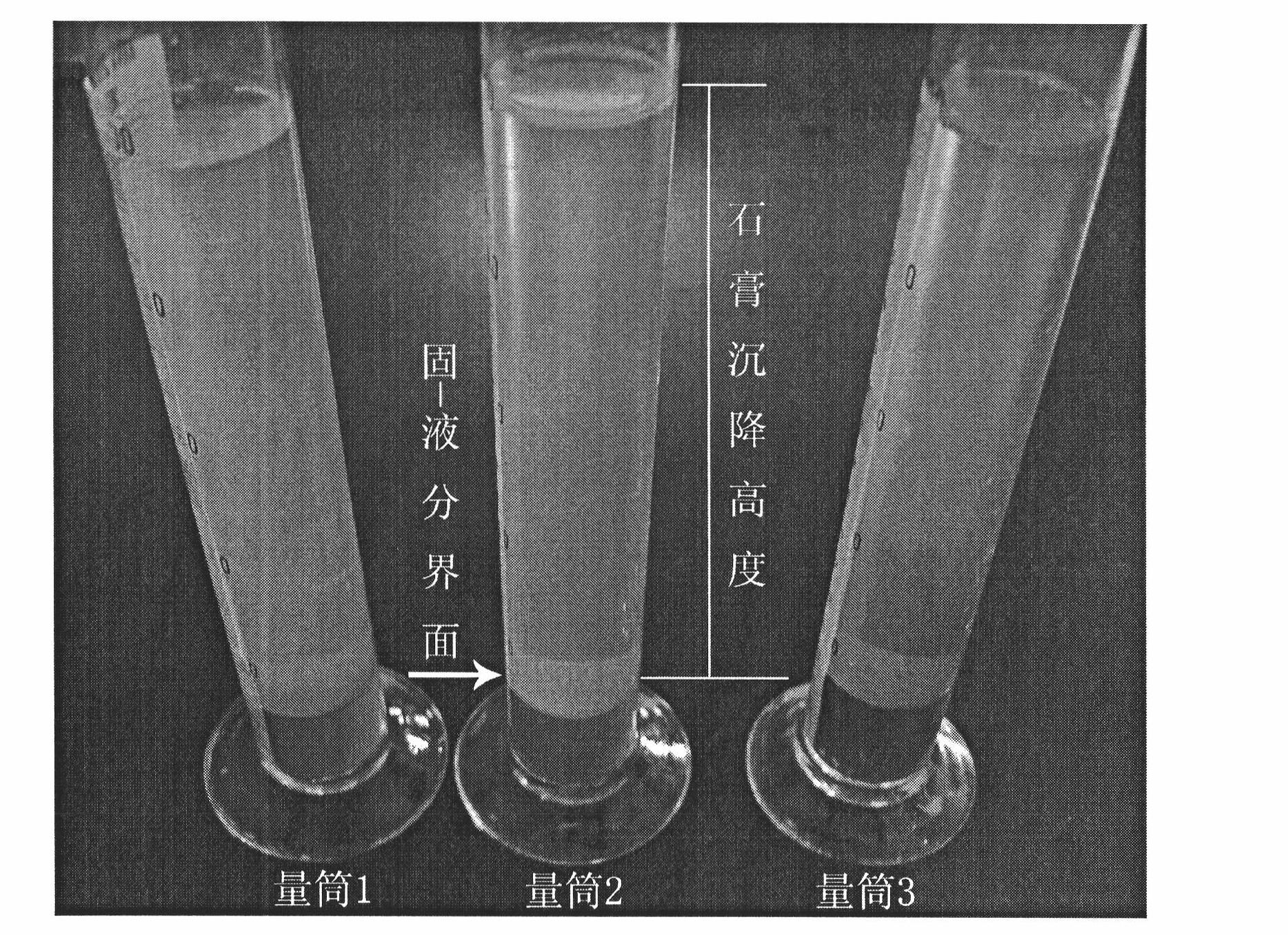

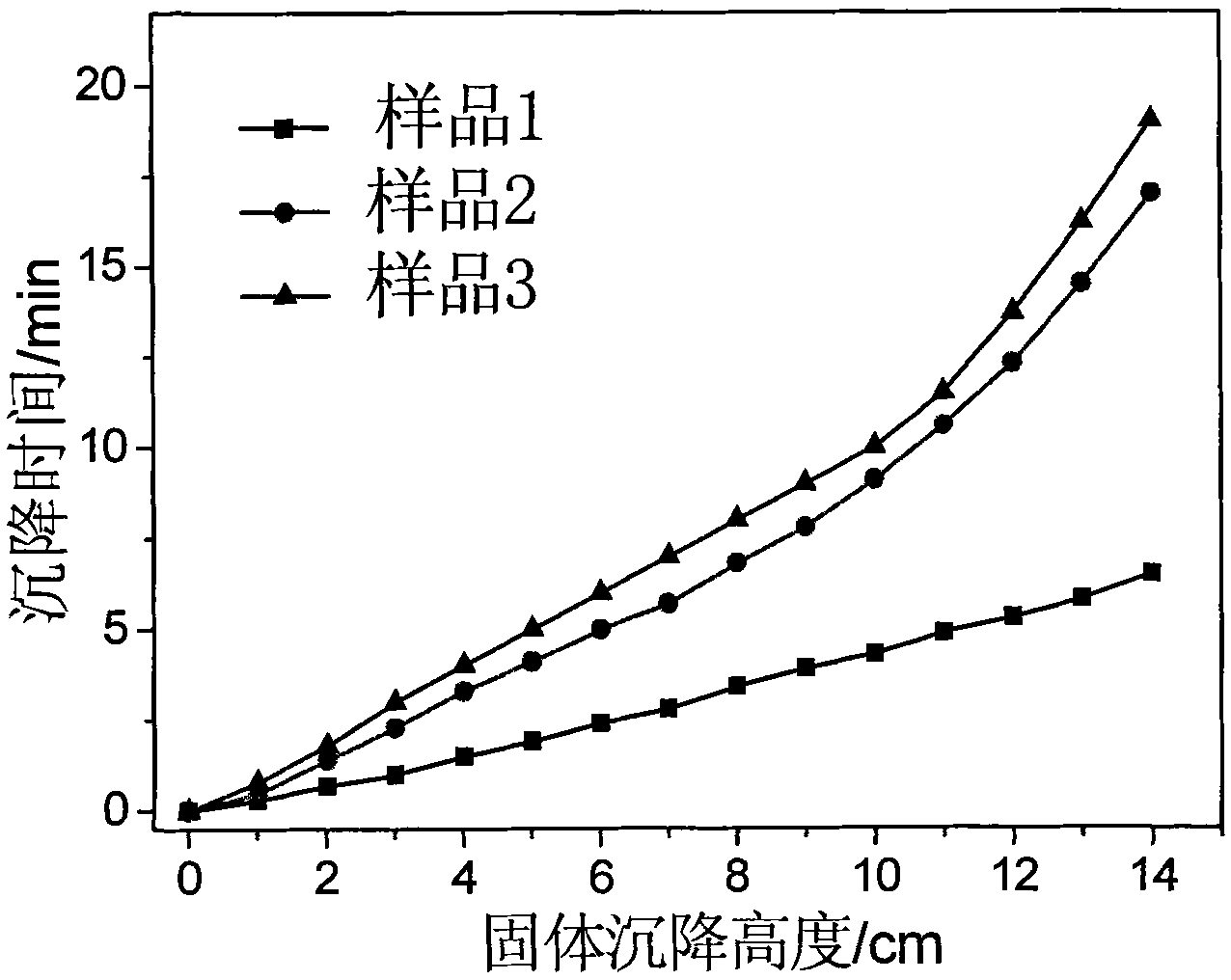

[0021] A method for judging the dehydration performance of different gypsums, the method is: take three different underflow slurries of the gypsum cyclone to be tested in a beaker, add water to adjust the density of the three slurries to 1.1g / ml, and use such as figure 1 Measure the three kinds of slurries with the same density to the 0cm scale line of the coordinate paper (marked as measuring cylinder 1, 2 and 3) in the measuring cylinder with the height scale coordinate paper attached to the outer wall of the shown, stir evenly, let it stand still, and measure the solid in each measuring cylinder reach the same settlement height (such as figure 2 Shown, the settlement height is the vertical distance between the liquid surface and the solid-liquid interface).

[0022] It is known through measurement that the time required for the solid settlement height in measuring cylinder 1 to stop at 14cm is 6.5 minutes, the time required for the solid settlement height in measuring cyli...

Embodiment 2

[0024] A method for judging the dehydration performance of different gypsums. The method is as follows: respectively take two different underflow slurries of the gypsum cyclone to be tested with a beaker, add water to adjust the density of the two slurries to 1.1g / ml, and use such as figure 1 Measure the two kinds of slurries with the same density to the 0cm scale line of the coordinate paper (marked as graduated cylinder d and e) respectively from the measuring cylinder with the height scale coordinate paper attached to the outer wall of the shown. The time required to settle height.

[0025] It takes 12 minutes for the sedimentation height of solids in graduated cylinder d to stop at 14 cm, and 12 minutes for the sedimentation height of solids in graduated cylinder e to stop at 14 cm. It can be seen that the time required for the solids in graduated cylinders d and e to reach the same sedimentation height is the same, indicating that the dehydration performance of gypsum put...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com