Hydraulic-driven automatic wire coil-loading device for frame winding machine

A frame stranding machine and hydraulic technology, applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve the problems of large auxiliary man-hours, high manufacturing costs, high labor intensity, etc., and achieve high work efficiency, convenient operation and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

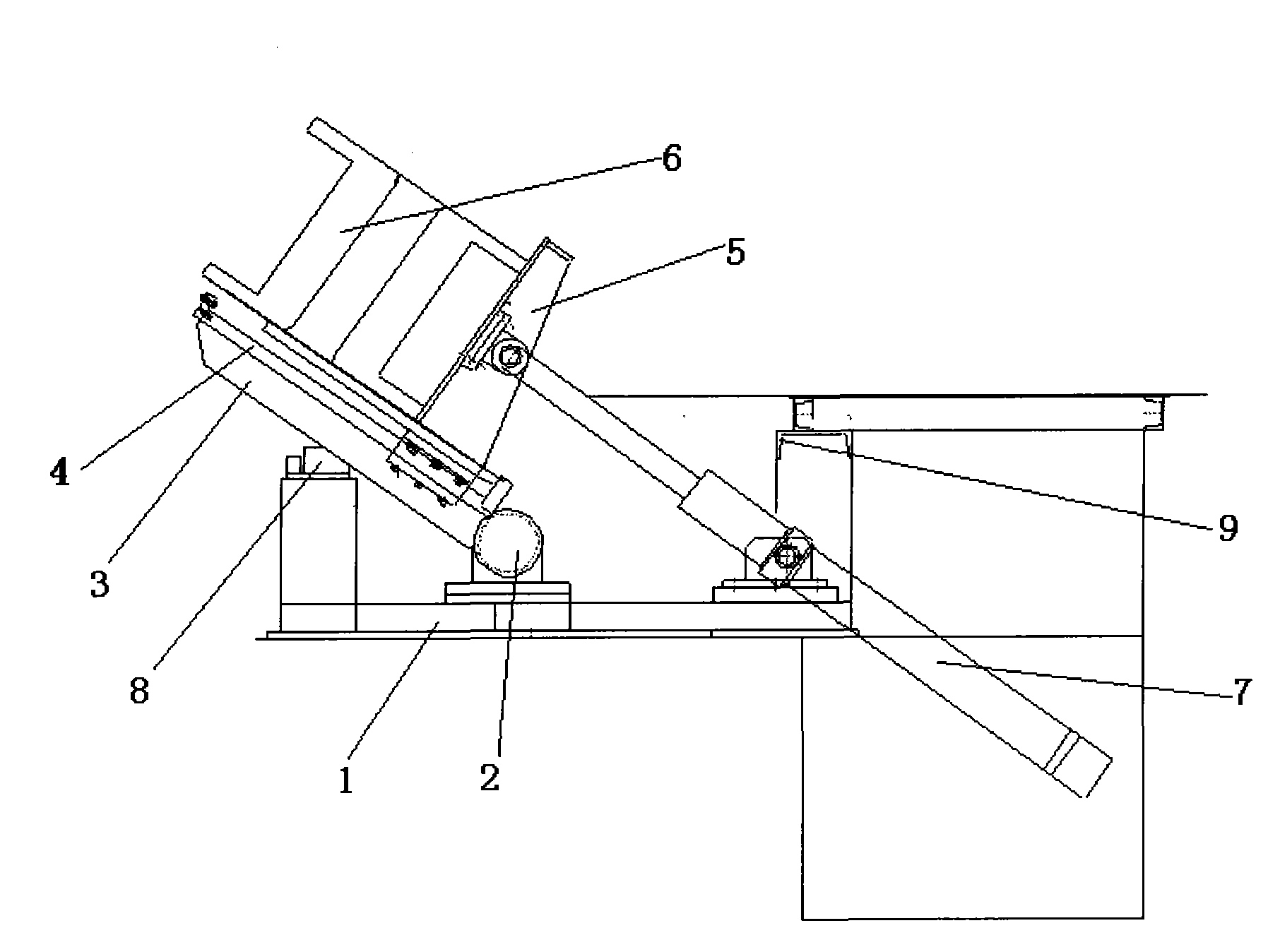

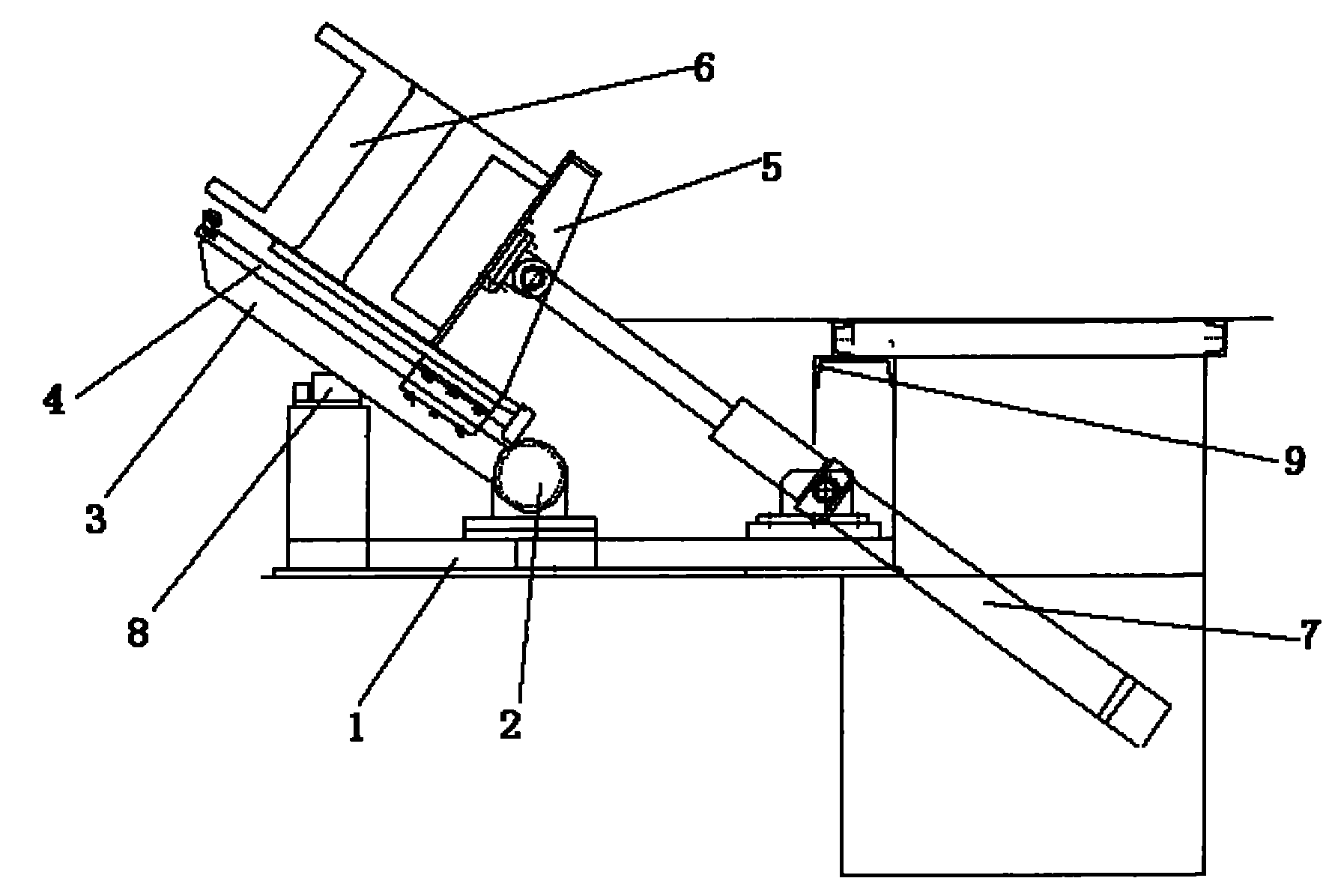

[0012] Referring to the accompanying drawings, the hydraulically driven automatic loading device of the frame winch includes an underframe 1, on which a fixed shaft 2 is rotatably installed, and the two ends of the fixed shaft are installed on the shaft seat 11, and the shaft seat 11 is fixed on the bottom frame On the fixed shaft 2, an overturn bracket 3 is fixedly installed, and a guide rail 4 is arranged on the overturn bracket 3, and an L-shaped right-angled wire reel bracket 5 is slidably installed on the guide rail 4, and a sliding seat is fixed on the wire reel bracket 5, The sliding seat cooperates with the guide rail 4 sliding guide, and the wire reel 6 is placed on the wire reel bracket 5; the hydraulic cylinder 7 is installed on the chassis 1 through the hinge shaft, and the piston rod of the hydraulic cylinder 7 is hinged with the bottom of the chassis 1; The front side of the turning bracket 3 has a turning limit platform 8 fixed on the chassis, and the turning bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com