Process for forming side electrode of chip concave type electrode network resistor

A side electrode, concave technology, used in resistors, resistance manufacturing, coating resistance materials, etc., can solve the problems of air flow end-face electrode filling holes cannot be guaranteed to be consistent, poor customer satisfaction, and inconsistent filling holes. Achieve the effect of overcoming the incomplete connection to form effective side electrodes, enhancing product market competitiveness and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

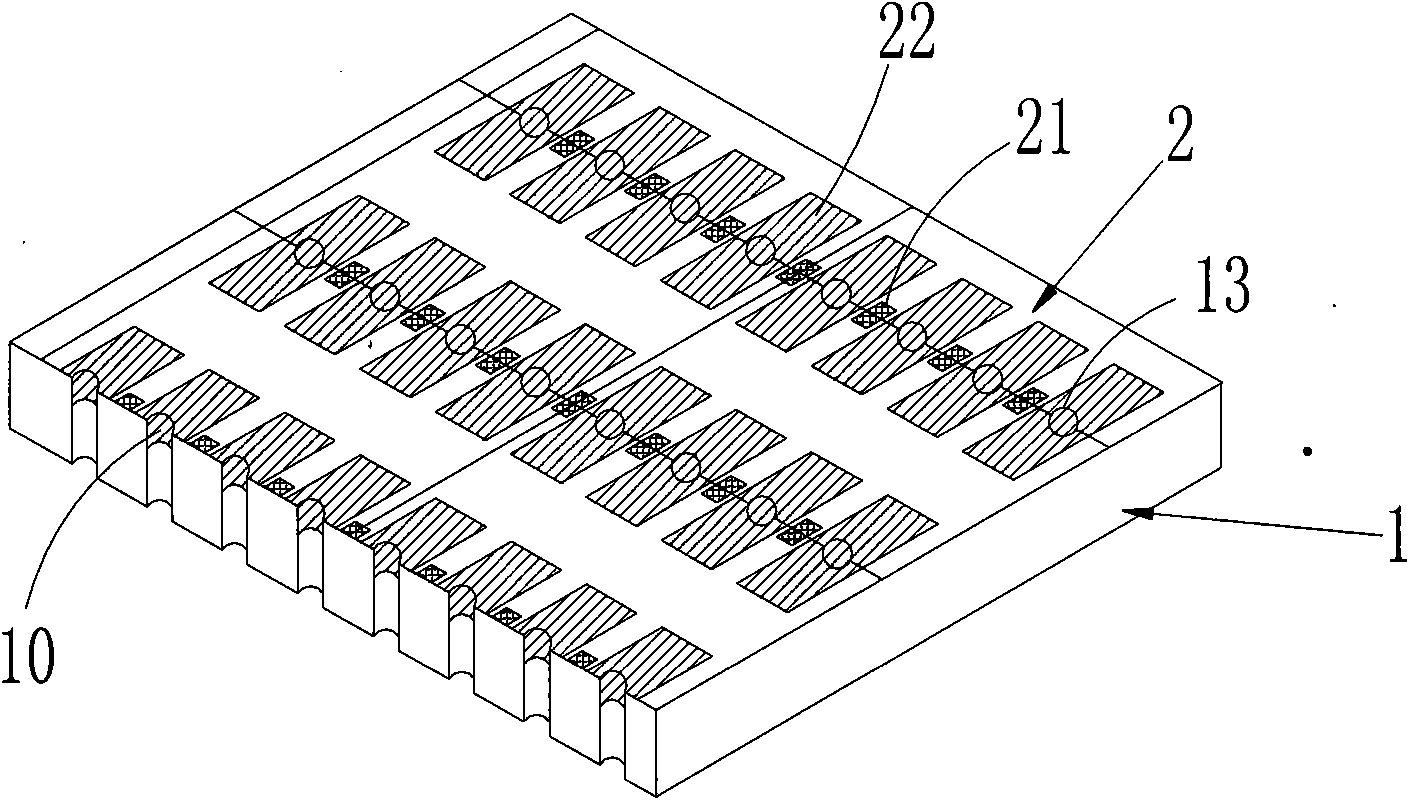

[0020] Embodiment: A side electrode formation process of patch concave electrode network resistance, based on the use direction, after printing the front electrode 22 on the upper surface 2 of the insulating substrate 1 corresponding to the perforation 13, each perforation 13 is filled. Thereby forming the side electrode conduction layer 10 on the upper part of each perforation 13 hole walls, the formation process of the side electrodes is as follows:

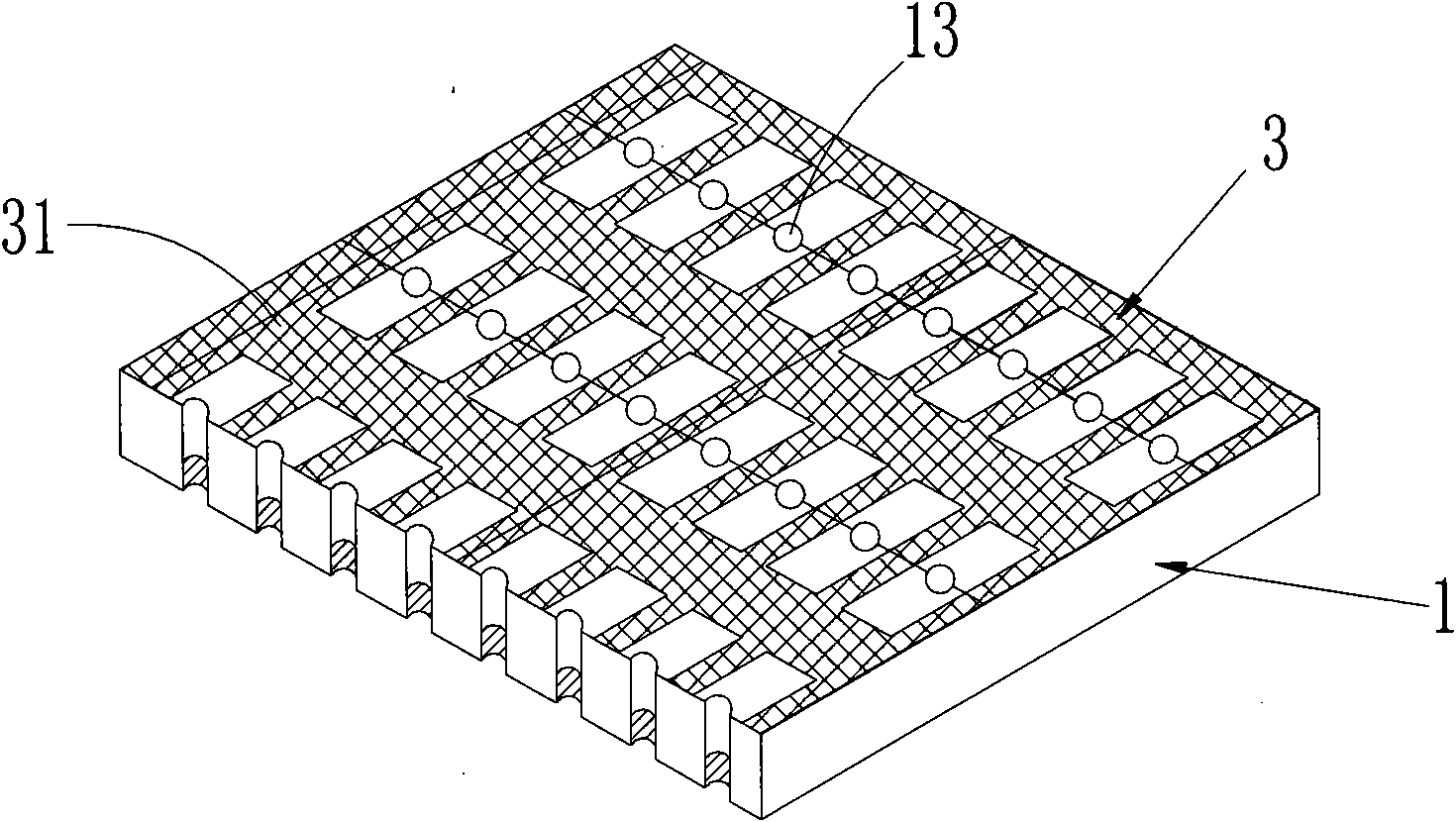

[0021] a. Print and form a mask layer 31 on the part of the lower surface 3 of the insulating substrate 1 corresponding to the position of the upper surface of the front electrode 22, and dry it;

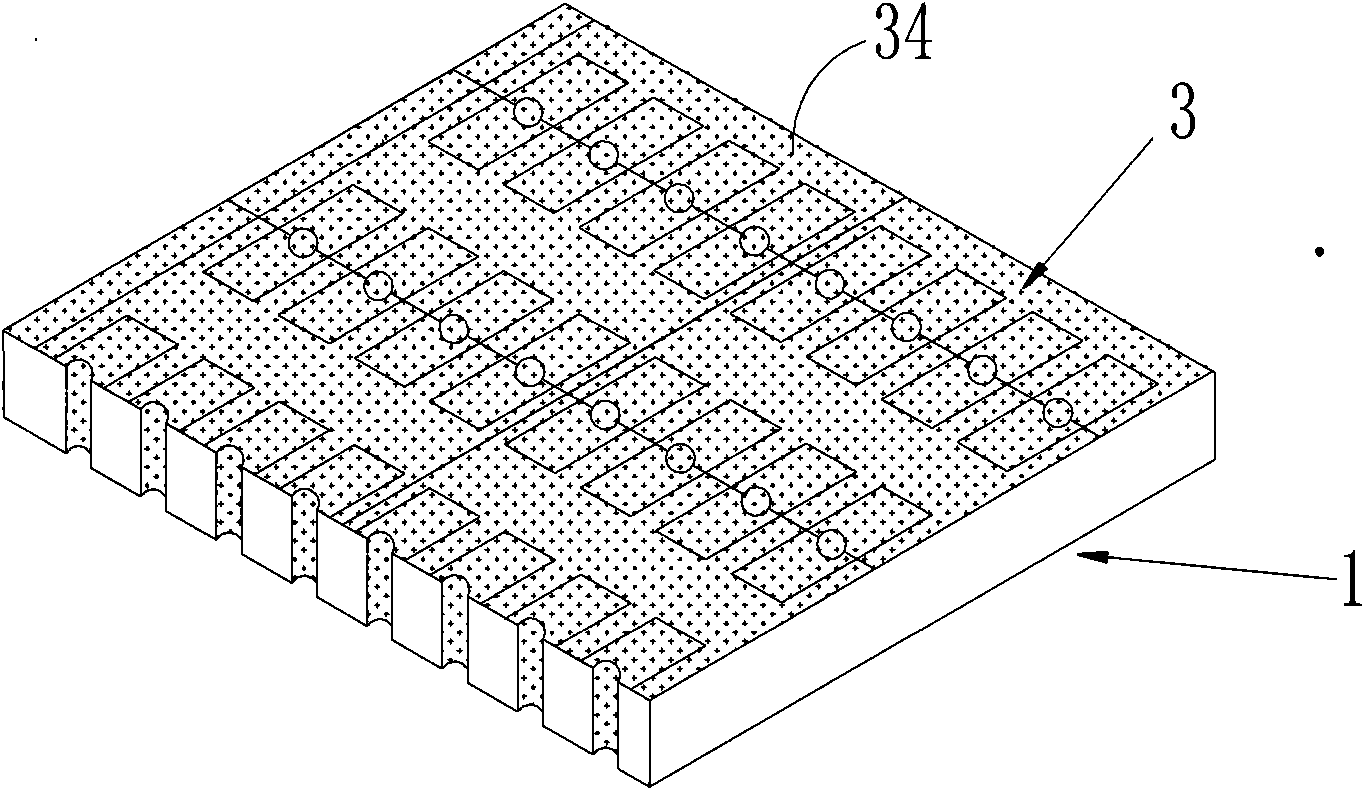

[0022] b. The lower surface 3 of the insulating substrate is sputtered, and the sputtering layer 34 is formed on the position of the mask layer 31, the hole wall of the perforation 13, and the lower surface 3 of the insulating substrate corresponding to the front electrode 22 on the upper surface (ie Sputtering is performed on the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com