Casting method and leveling tool for large multi-blade casting

A multi-blade and casting technology, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems that the mechanical properties cannot fully meet the technical requirements, and achieve the effects of shortening the production cycle, reducing carbon planing, and ensuring the quality of castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The casting method and leveling tool for large multi-blade castings, taking the 18.0 hydraulic dynamometer rotor as an example, includes the following steps:

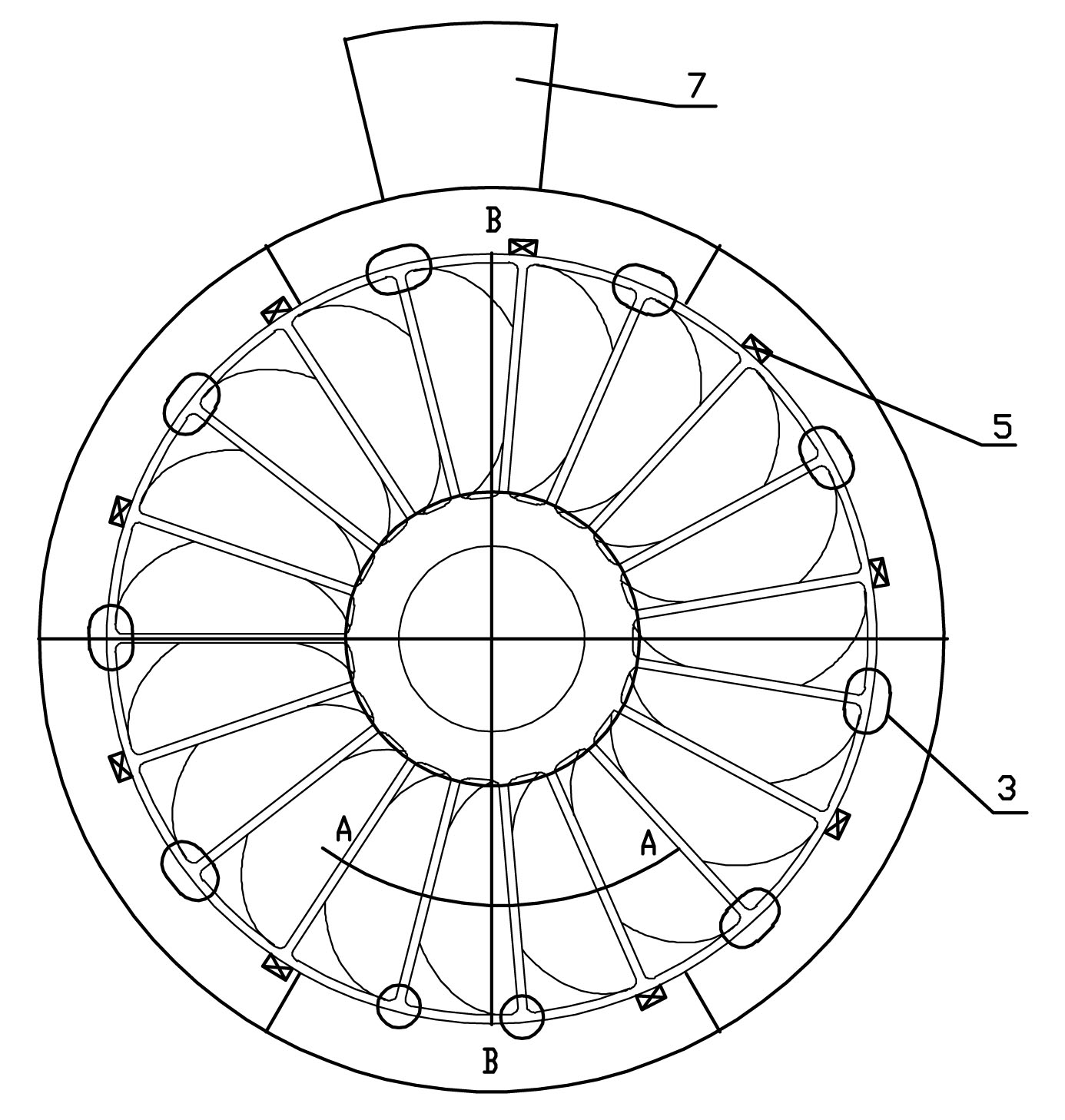

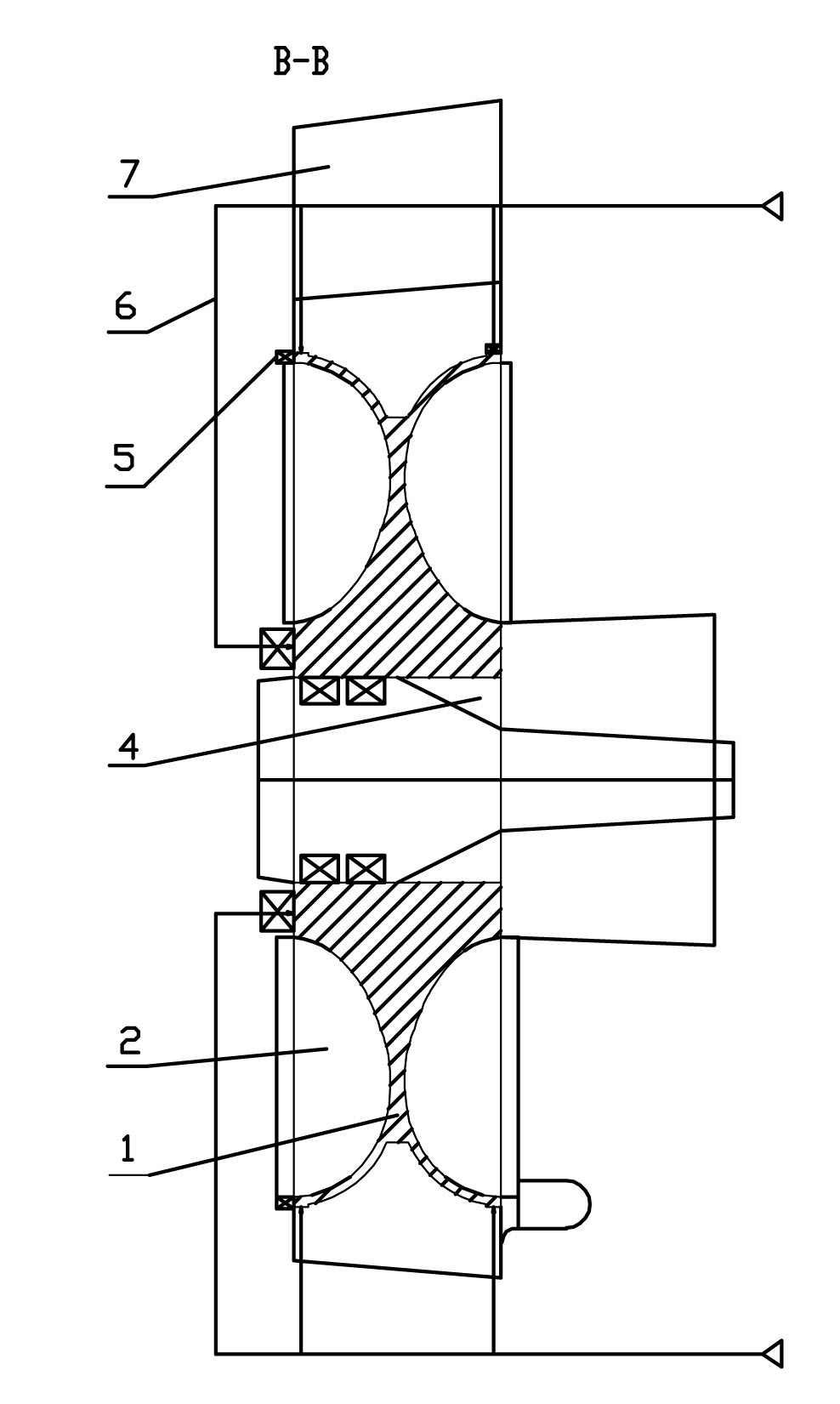

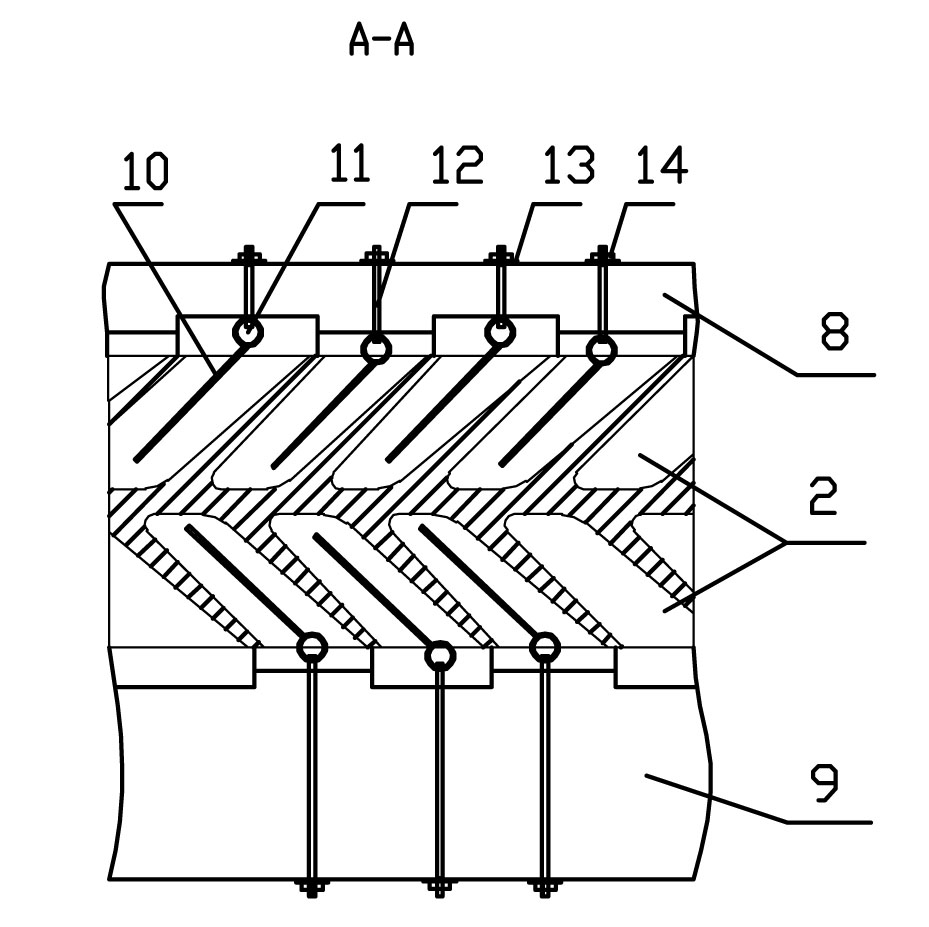

[0034] 1) Prepare the casting process according to the 18.0 hydraulic dynamometer rotor drawing, the process diagram is as follows figure 1 , figure 2 , image 3 shown.

[0035] The solid wood sample, the outer mold is made into a whole, the radial scale is 1.6%, the axial scale is 2.0%, and the drafting angle is 1°; Production, the height is staggered to prevent the cumulative error of blade position and wall thickness size; the outer mold makes a lower core sand filling plate 7 for blade sand core 2, leaving space for the bottom core of the last blade sand core 2.

[0036] 2) Making a leveling tool for blade sand core 2, the leveling tool is a lever mechanism, one end is provided with a quick joint 15, the middle is provided with a lifting ring 18, and the other end is provided with a moving weight 16. ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com