Multi-groove type hydrostatic guideway and fine punching pressure machine

A static pressure guide rail and press technology, applied to presses, manufacturing tools, etc., can solve the problems of high cost, high processing technology requirements, complex structure, etc., and achieve the effect of strong bearing capacity, low cost and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

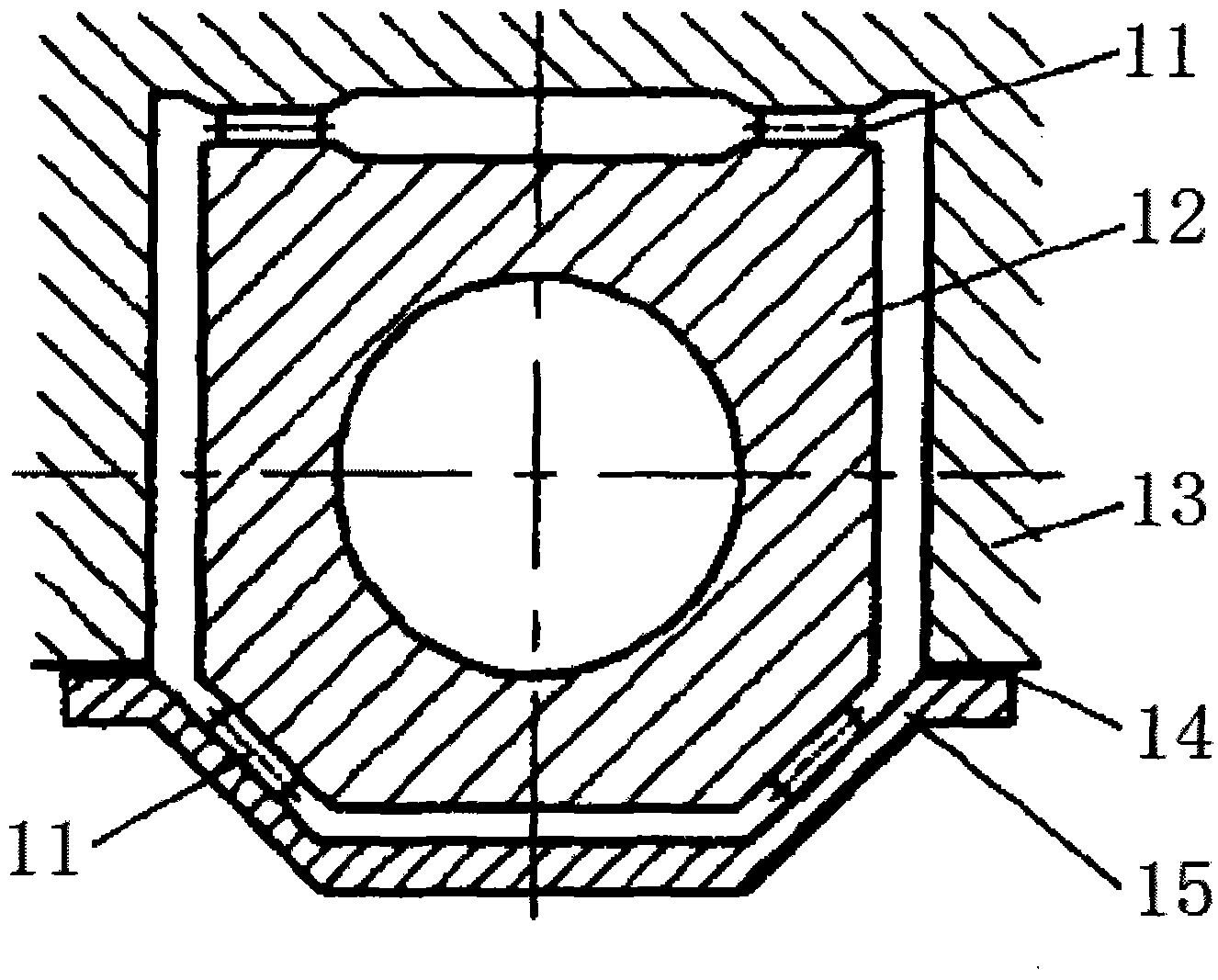

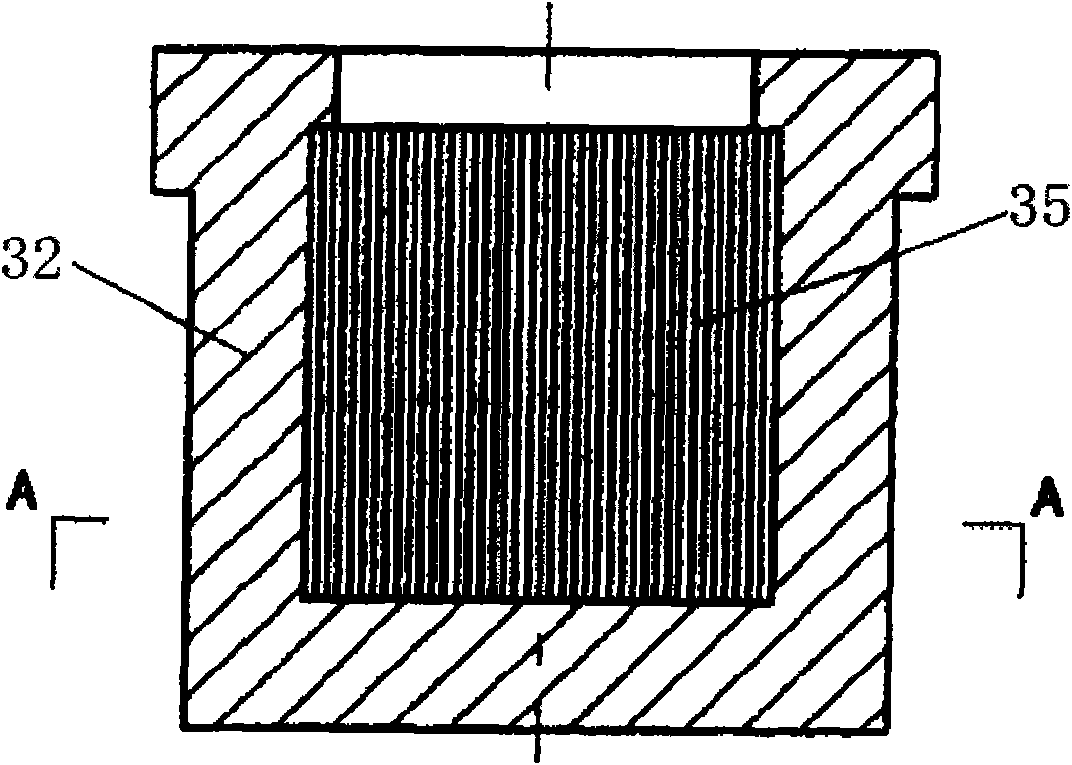

[0017] The preferred embodiment of the multi-groove static pressure guide rail of the present invention is shown in Figure 3, comprising a master cylinder, a plunger is arranged in the master cylinder, the outer wall of the plunger is a smooth outer wall, and the main cylinder The inner wall of the cylinder is longitudinally provided with a plurality of diversion grooves.

[0018] The depth of the diversion groove is 1-2 times of the gap between the master cylinder and the plunger, and the plurality of diversion grooves are continuously covered with the inner wall of the master cylinder.

[0019] The cross section of the diversion groove is triangular, and may also be other shapes.

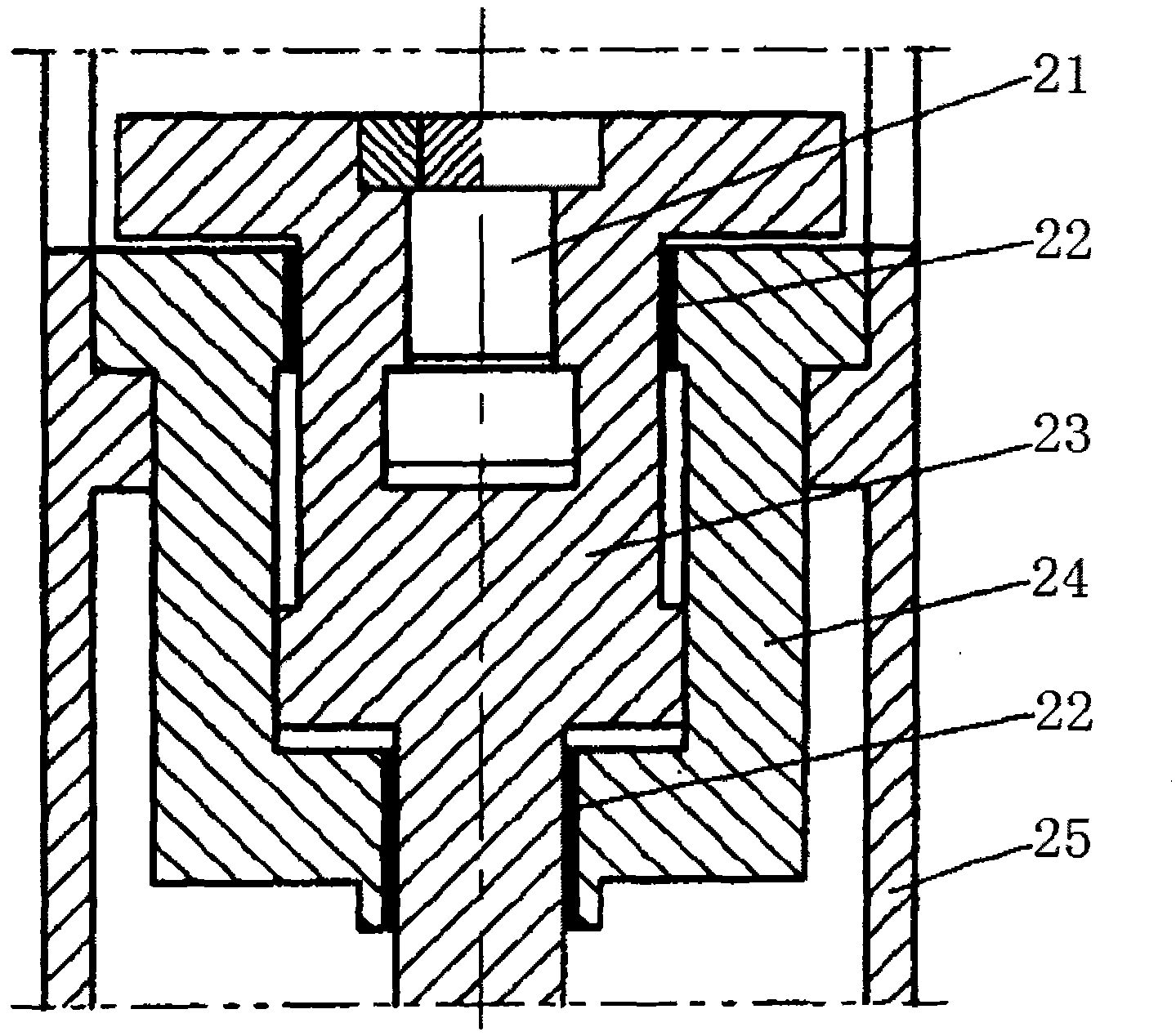

[0020] Such as Figure 5 As shown, there is an annular high-pressure groove in the middle of the inner wall of the master cylinder, and the inner walls of the master cylinder on both sides of the high-pressure groove are respectively covered with diversion grooves, and the two ends of the master ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com