Method for cleaning positive plate after formation of lead-acid battery plates

A technology of lead-acid batteries and positive plates, applied in the field of batteries, can solve problems such as difficult to control the electrolyte content of the positive plates, affect the dry charging performance of batteries, increase the production cost of enterprises, etc., achieve remarkable water saving effects, save tap water, reduce The effect of business costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

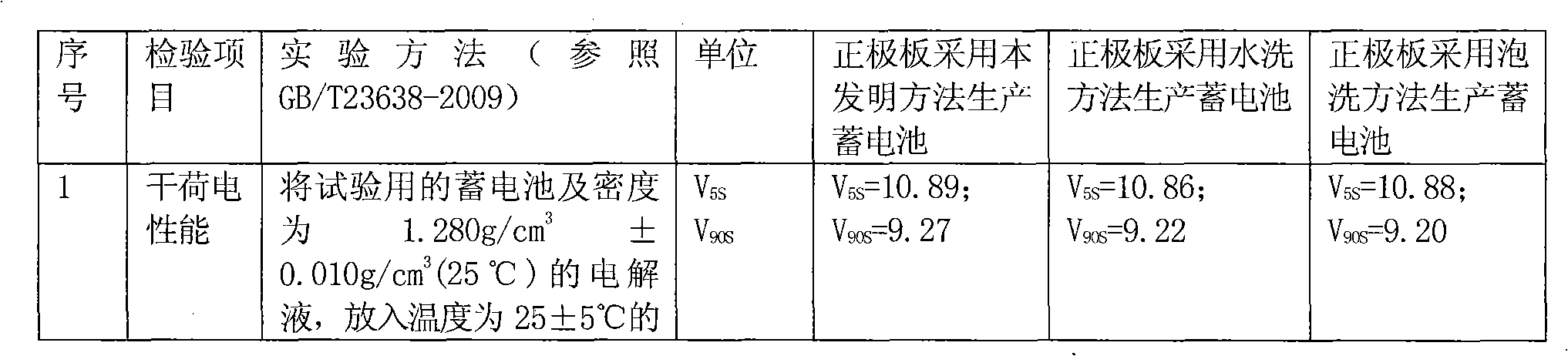

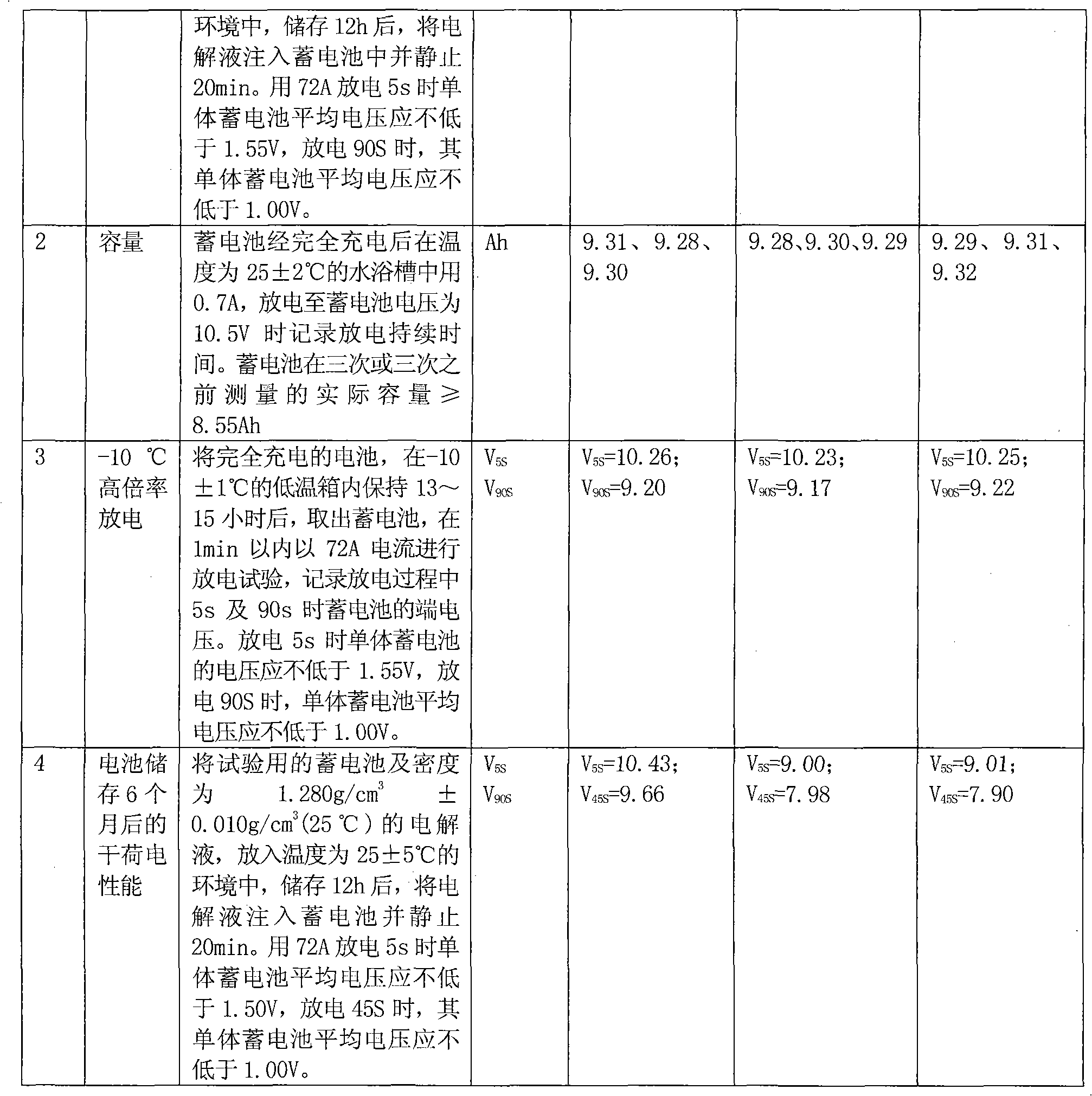

Embodiment 1

[0019] Example 1: Immerse the positive plate that has been formed out of the tank into a sodium hydroxide soaking solution with a concentration of 1%. The positive plate needs to be completely immersed in the sodium hydroxide soaking solution for 6 minutes. The positive plate is taken out from the soaking solution and measured The pH value of the plate surface is 4, and the soaked positive plate is sent to a dryer for drying.

Embodiment 2

[0020] Example 2: Immerse the positive plate that has been formed and discharged from the tank into a sodium hydroxide soaking solution with a concentration of 2%. The positive plate needs to be completely immersed in the sodium hydroxide soaking solution for 2 minutes. The pH value of the plate surface is 6, and the soaked positive plate is sent to a dryer for drying.

Embodiment 3

[0021] Example 3: Immerse the positive plate that has been formed and discharged from the tank into a sodium hydroxide soaking solution with a concentration of 1.5%. The positive plate needs to be completely immersed in the sodium hydroxide soaking solution for 4 minutes. The positive plate is taken out from the soaking solution and measured The pH value of the plate surface is 5, and the soaked positive plate is sent to a dryer for drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com