Fixing method for removing abnormal sound of backlight light tube

A fixing method and backlight technology, applied in the field of fixing, can solve the problems of the lamp tube jumping off, breaking, easy to generate resonance abnormal sound, etc., to achieve the effect of firm fixation, simple fixing method, and elimination of resonance abnormal sound.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

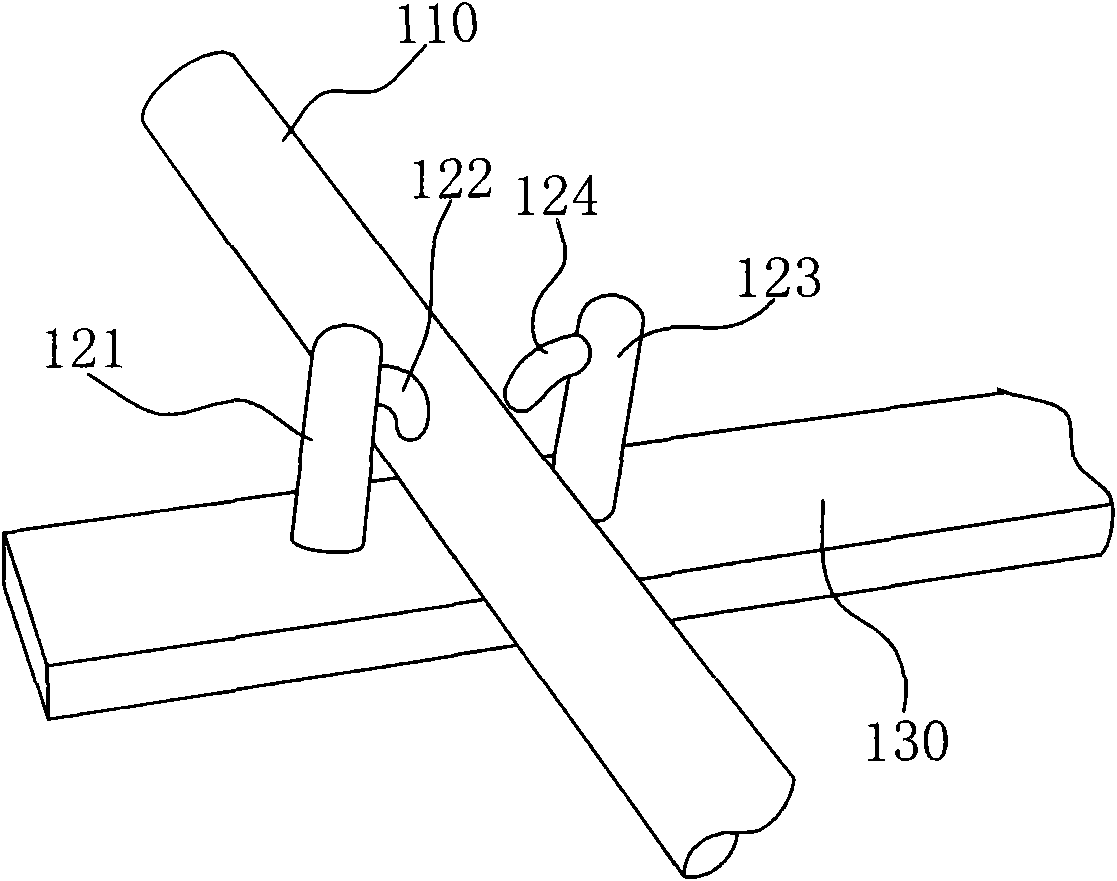

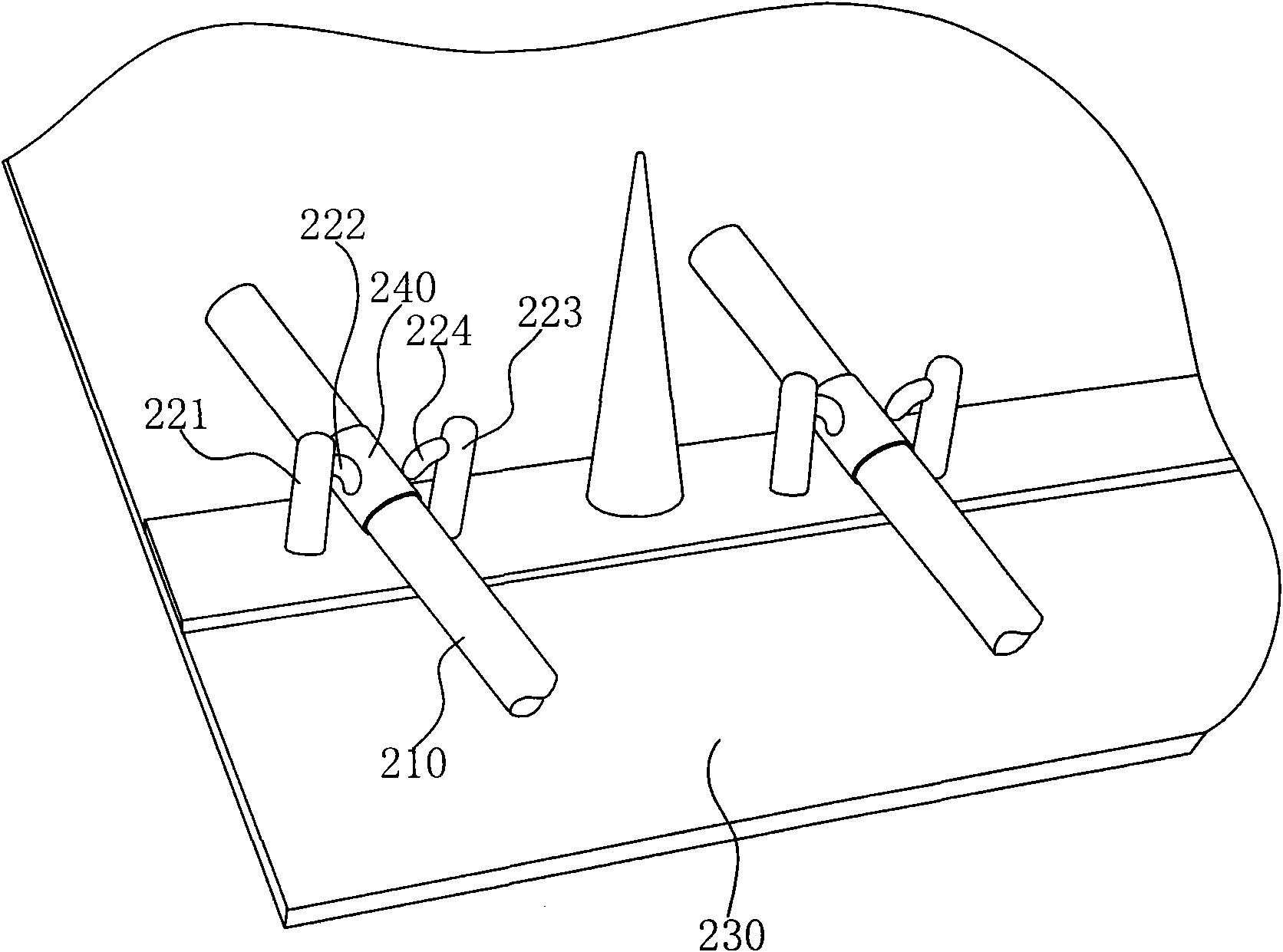

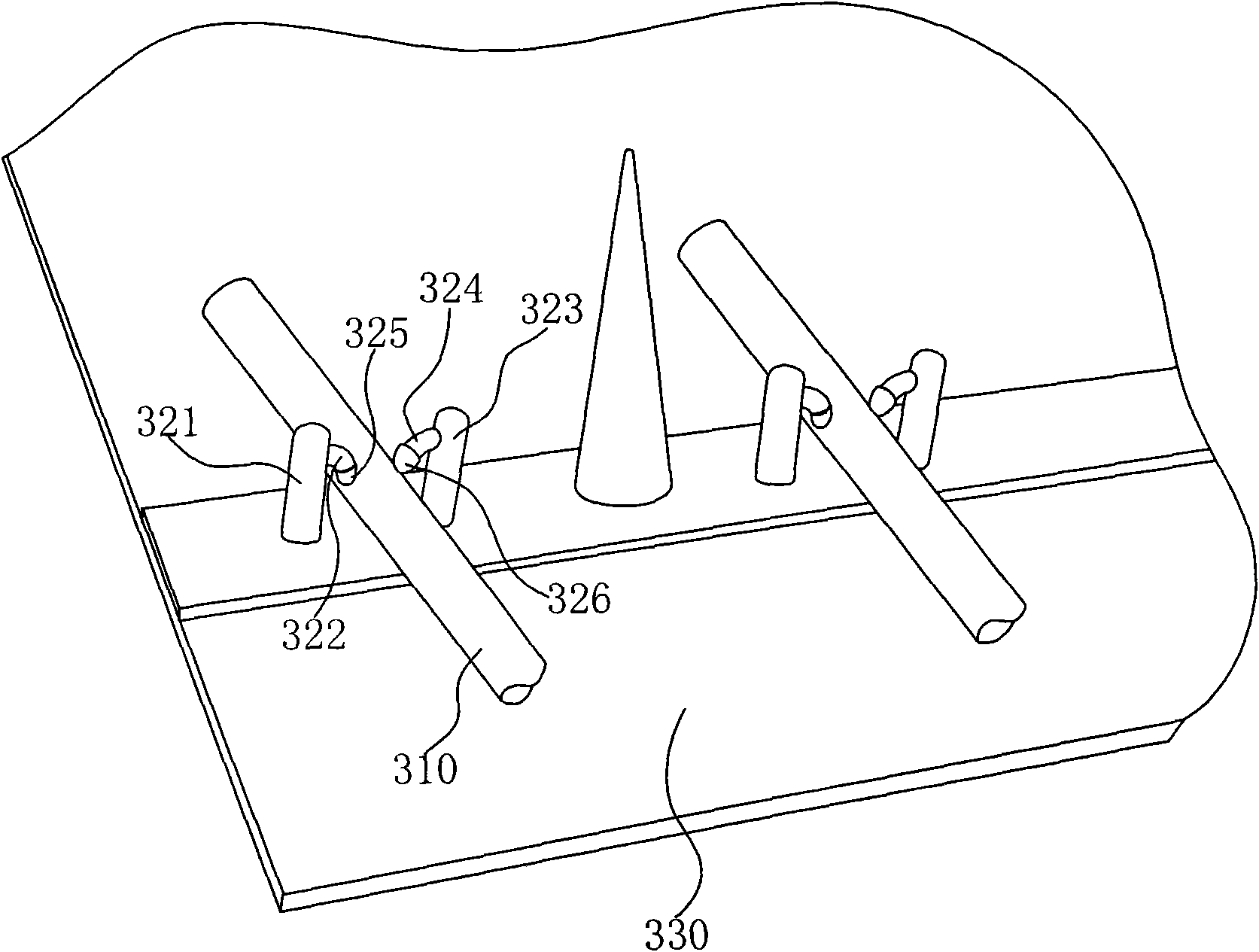

[0021] The fixing method for eliminating the abnormal sound of the backlight lamp tube is applicable to the backlight source of the liquid crystal display panel, that is, the fixing of the backlight lamp tube. Such as figure 1 As shown, in this embodiment, a group of buckles are used to fix the backlight tube, and the buckles are distributed and fixed on the back plate 130. The buckles include two opposite columns, each of which is obliquely A hook is set, and the hooks 122, 124 of the buckle and the columns 121, 123 jointly fix the backlight tube 110 on the backboard 130, and a light-transmitting adhesive tape is wound outside the clamping part of the backlight tube. The light tape isolates the outer wall of the backlight tube from the clamping part, and the light-transmitting tape or strip is a polymer adhesive tape. The light-transmitting adhesive tape can be replaced by a polymer light-transmitting rubber strip, and the light-transmitting glue strip can be formed on the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com