Secondary air injection high-efficiency ultralow temperature heat pump unit

A pump unit and ultra-low technology, applied in heat pumps, refrigerators, compressors, etc., can solve the problems of air source heat pumps not working properly, restricting the promotion and application of air source heat pumps, etc., to improve the normal operating temperature range and save energy. Ideal and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing.

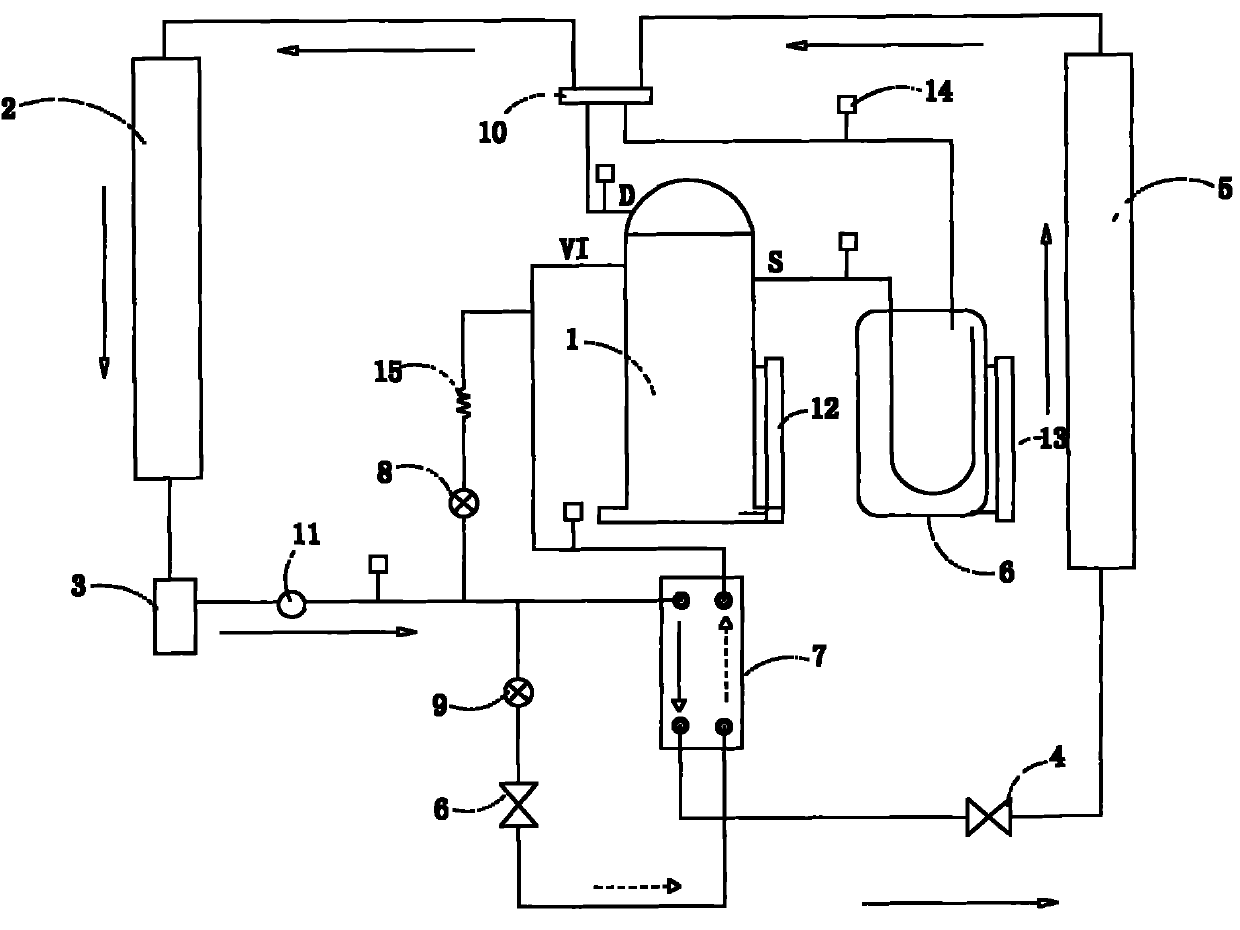

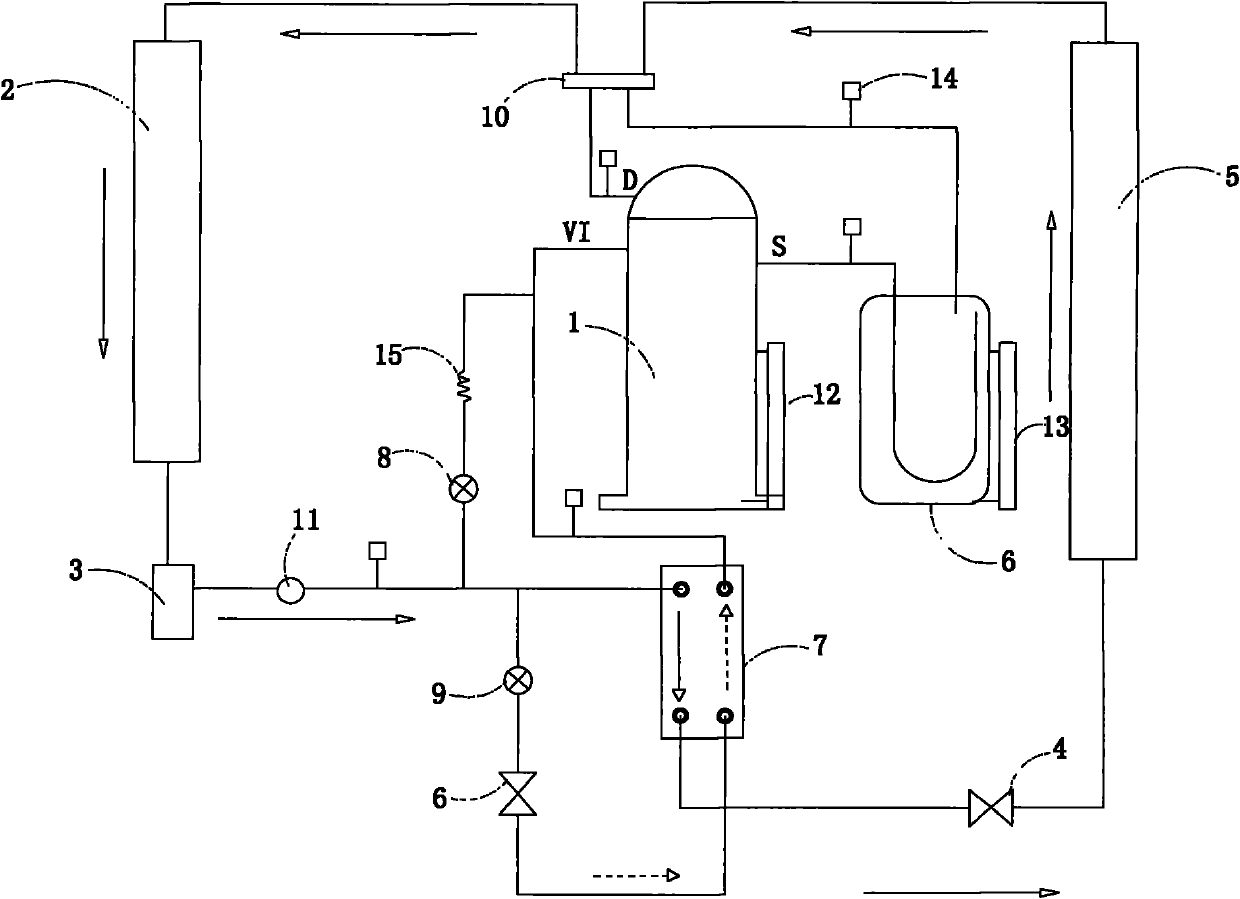

[0011] The specific embodiment of the present invention is as figure 1 As shown, a secondary air injection high-efficiency ultra-low temperature heat pump unit includes a compressor 1, a condenser 2, a liquid storage tank 3, a thermal expansion valve 4, an evaporator 5, and a gas-liquid separator 6, and each component is connected in sequence to form a circuit. Between the compressor 1 and the liquid storage tank 3, there is also a compressor air supply device, which includes a jet expansion valve 6, an economizer 7, a first solenoid valve 8 and a second solenoid valve 9; In parallel, the first solenoid valve 8 is directly connected to the compressor 1, the second solenoid valve 9 is connected in series with the jet expansion valve 6 and the economizer 7 in turn, and the economizer 7 is connected to the compressor 1 again.

[0012] In this embodiment, the compressor 1 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com