Heat resisting motor

A technology with high temperature resistance and main shaft, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of short service life and high noise, and achieve the effect of long service life, low noise and reasonable and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

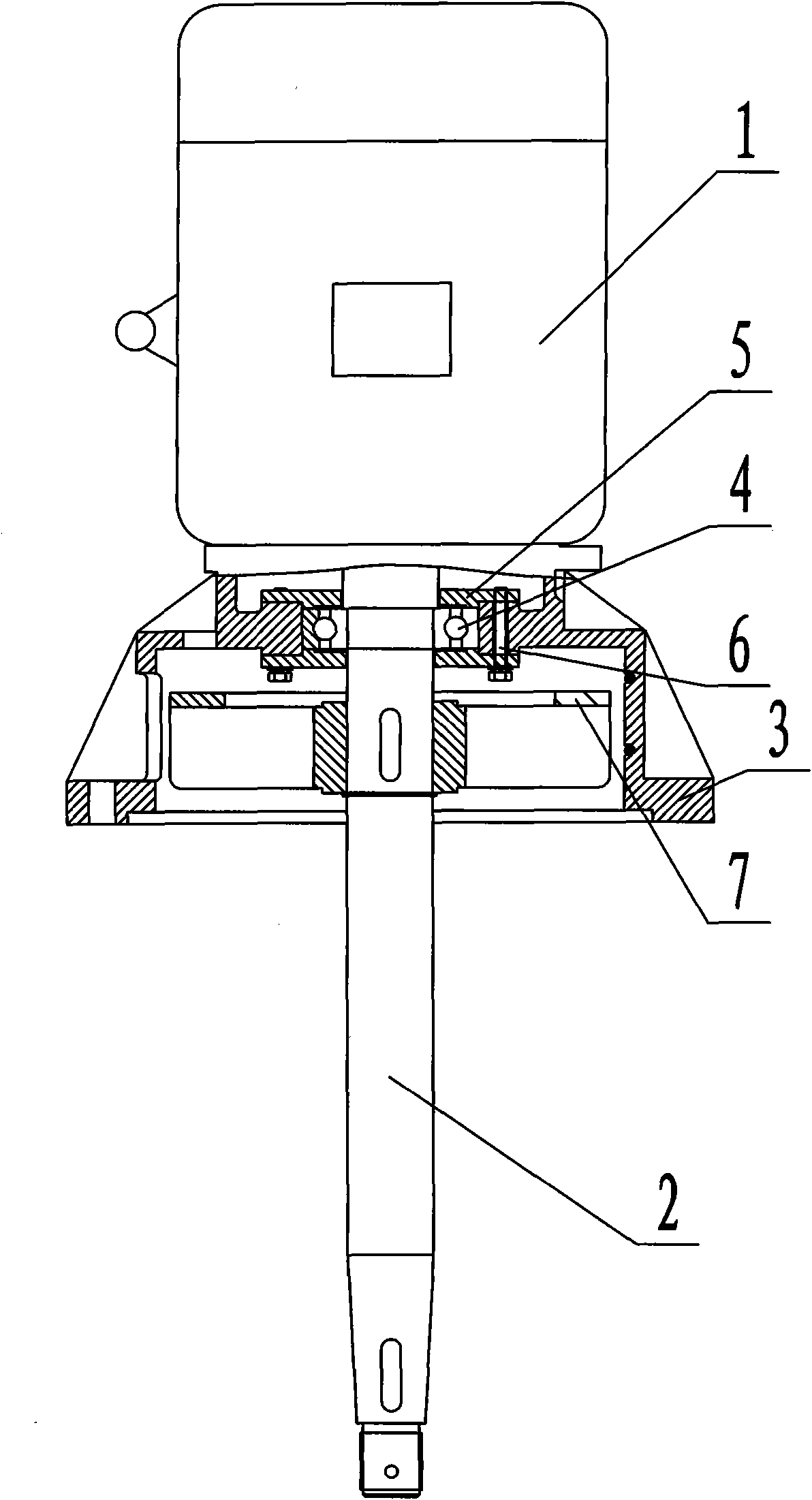

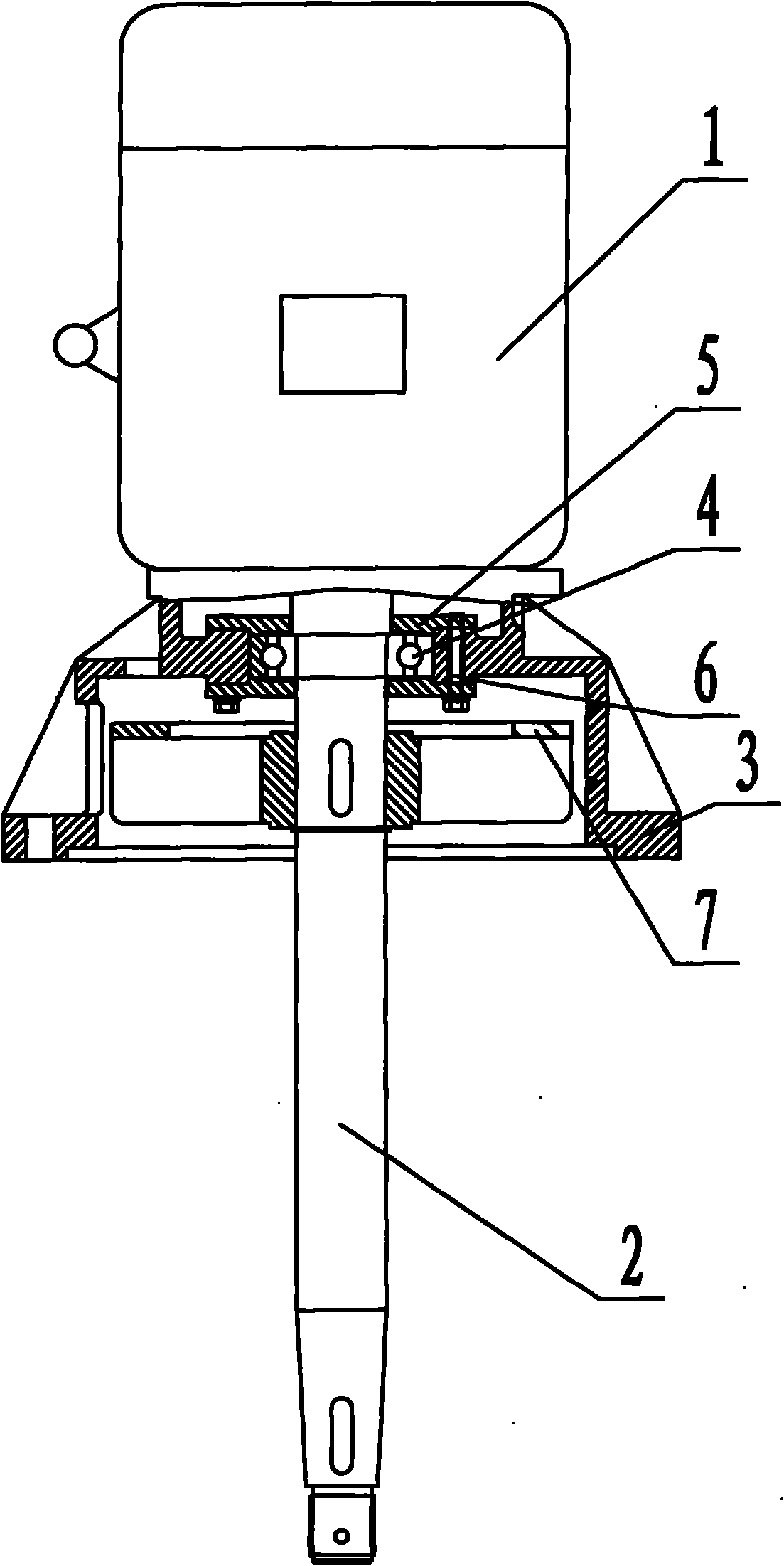

[0009] Such as figure 1 As shown, the high temperature resistant motor includes: motor 1, main shaft 2 and motor front plate 3. The main shaft 2 is set at the bearing position of the front plate through a bearing 4, and the bearing is fixedly arranged in the motor front plate 3 through a bearing cover 5 and screws 6, A heat-dissipating aluminum wind wheel 7 is provided on the main shaft 2 in the front connecting plate 3 of the motor.

[0010] When the high-temperature resistant motor of the above structure is used, when the motor 1 is working, the main shaft 2 rotates, thereby driving the heat-dissipating aluminum wind wheel 7 arranged on the main shaft 2 to rotate, which can effectively dissipate heat and protect the bearing, and can continuously operate at a furnace temperature below 800°C , And does not require any coolant, only need to inject high-temperature grease regularly to protect the bearing, reasonable and novel structure, labor-saving installation, excellent mechanic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com