Cold forming method for bimetallic T-shaped three-way pipe

A technology of three-way pipe fittings and bimetallic composite pipes, which is applied in the field of metal pipe fittings processing, can solve the problems of radial deformation, small branch pipe height, serious accumulation, etc., and achieve the effect of improving utilization rate and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

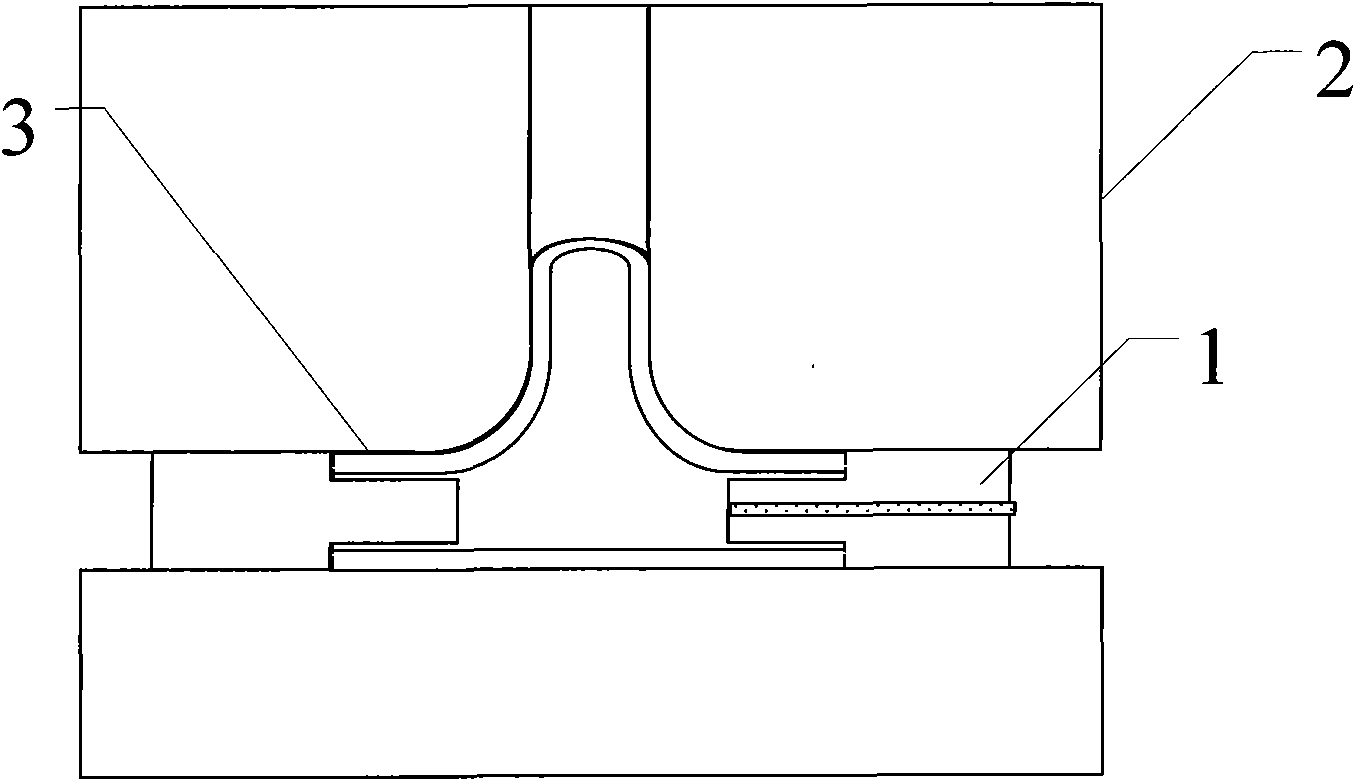

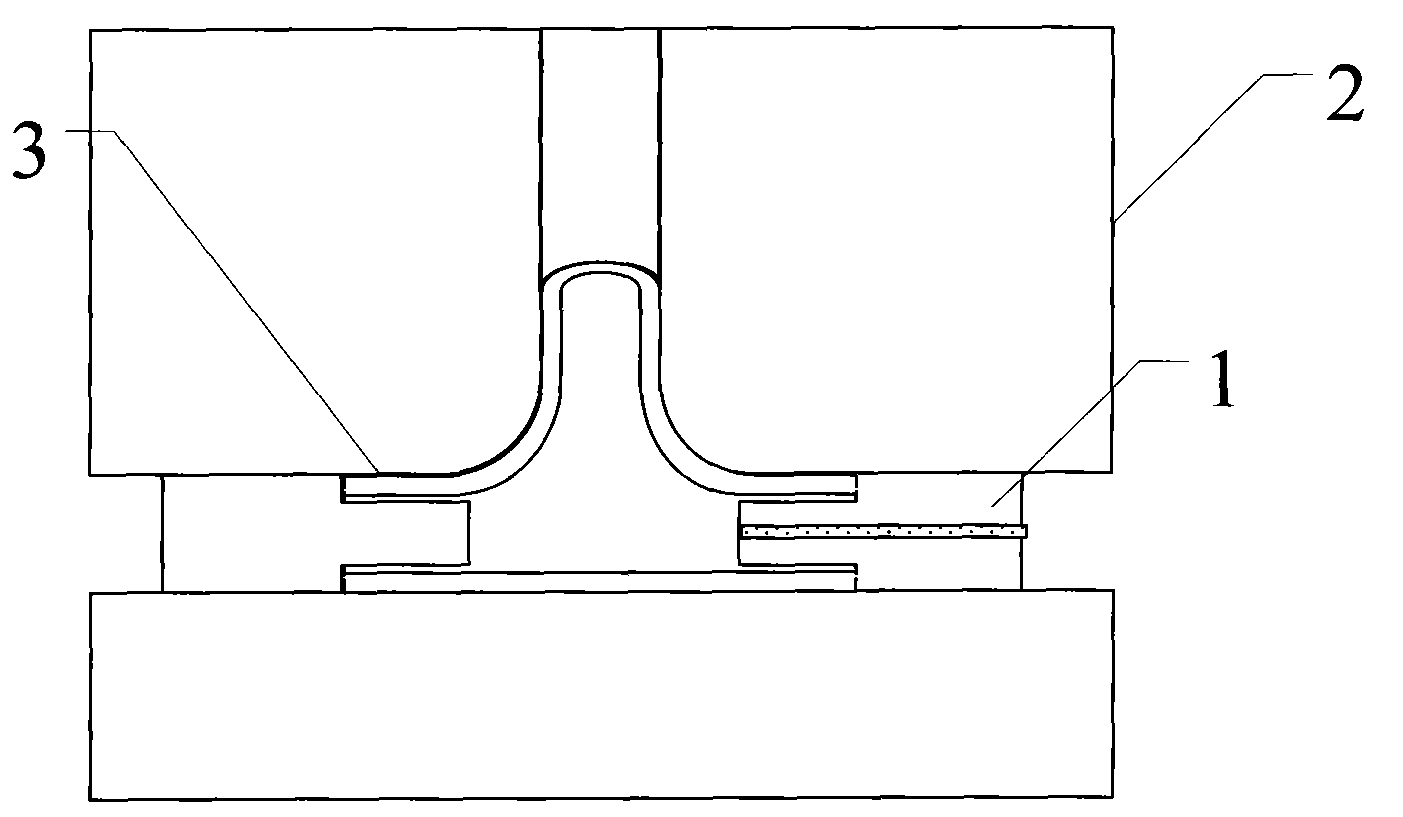

[0019] The bimetallic composite pipe is blanked, the cladding of the bimetallic composite pipe is cleaned, and the attachments on the inner surface are removed. Then the bimetal composite pipe is placed in the lower die of the forming die 2 and positioned;

[0020] Insert the thin ends of the two stepped shaft punches 1 into the two ends of the bimetallic composite pipe respectively; after the upper die and the lower die are closed, inject 30MPa hydraulic oil from the hole on the stepped shaft punch 1, and the bimetallic composite pipe The branch pipe is formed under the action of the expansion force of the hydraulic oil. In order to supplement the material to the branch pipe, the stepped shaft punch 1 squeezes the two ends of the bimetallic composite pipe, and the bimetallic composite pipe is formed under the action of the stepped shaft punch 1 and the forming die 2. The composite pipe is formed into a semi-finished bimetallic T-shaped tee fitting at one time 3;

[0021] The...

Embodiment 2

[0025] The bimetallic composite pipe is blanked, the cladding of the bimetallic composite pipe is cleaned, and the attachments on the inner surface are removed. Then the bimetal composite pipe is placed in the lower die of the forming die 2 and positioned;

[0026] Respectively extend the thin ends of the two stepped shaft punches 1 into the two ends of the bimetal composite tube; set the loading path of the internal pressure and the feed displacement of the punches, and set the feed displacement of the stepped punch 1 as One-half of the total feed displacement. After the mold is closed, 115MPa hydraulic oil is passed through the hole in the center of the stepped punch 1, and the bimetallic composite pipe forms a branch pipe under the action of the expansion force of the hydraulic oil. At both ends, under the combined action of the stepped shaft punch 1 and the forming die 2, the bimetallic composite pipe undergoes plastic deformation along the forming die with planar charact...

Embodiment 3

[0032] The bimetallic composite pipe is blanked, the cladding of the bimetallic composite pipe is cleaned, and the attachments on the inner surface are removed. Then the bimetal composite pipe is placed in the lower die of the forming die 2 and positioned;

[0033] Respectively extend the thin ends of the two stepped shaft punches 1 into the two ends of the bimetal composite tube; set the loading path of the internal pressure and the feed displacement of the punches, and set the feed displacement of the stepped punch 1 as One-third of the total feed displacement. After the mold is closed, the high-pressure liquid is passed through the hole in the center of the stepped punch 1, and the bimetallic composite pipe forms a branch pipe under the action of the bulging force of the high-pressure liquid. Under the combined action of the stepped shaft punch 1 and the forming die 2, the bimetallic composite pipe undergoes plastic deformation along the forming die with planar features un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com