Side portal frame type automatic assembling and disassembling manipulator

An automatic loading and unloading and manipulator technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as the inability to use large-scale loading and unloading machinery, the impact on the safety of operators, and the short distance of loading and unloading, and achieve obvious creativity and novelty. The effect of personnel safety and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

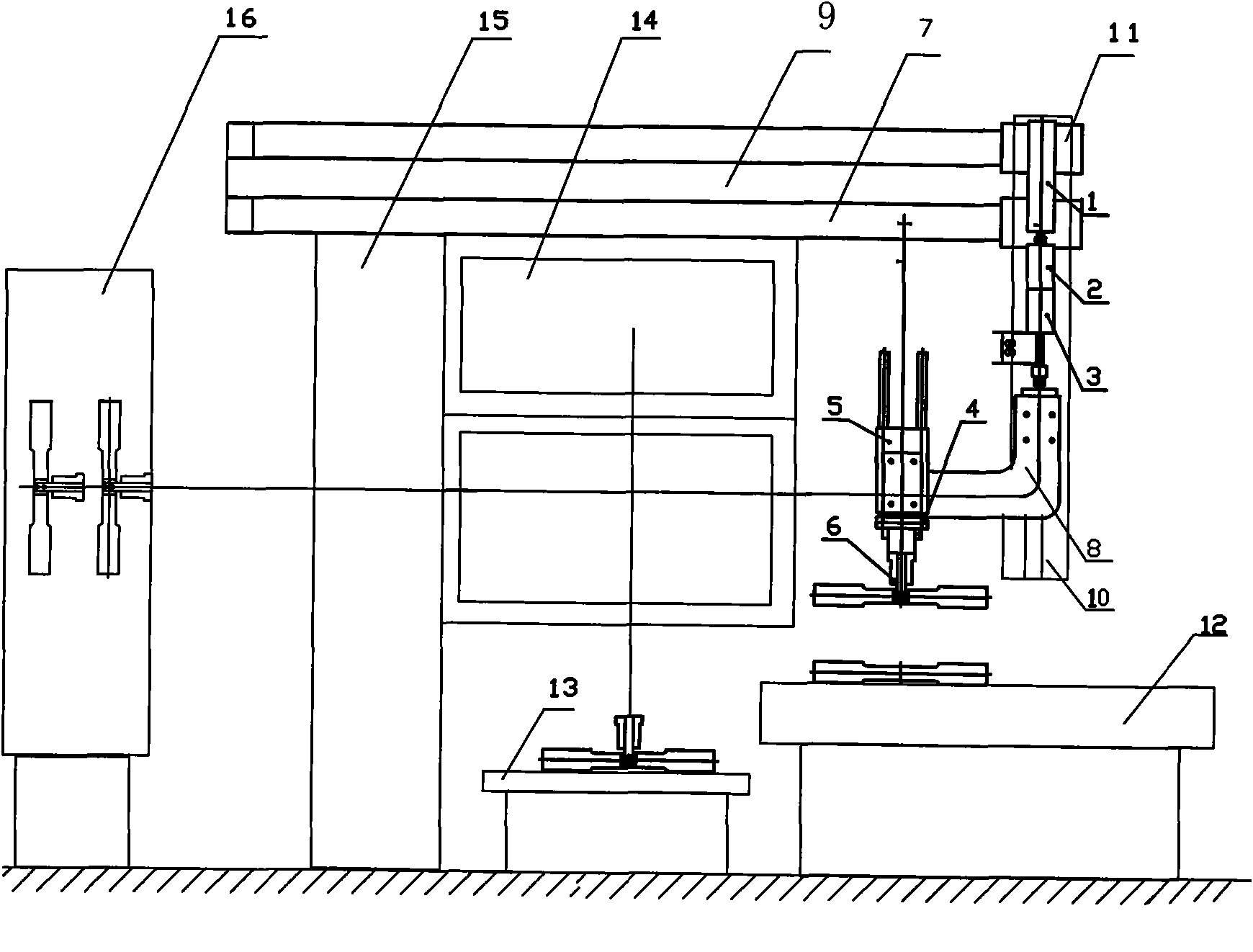

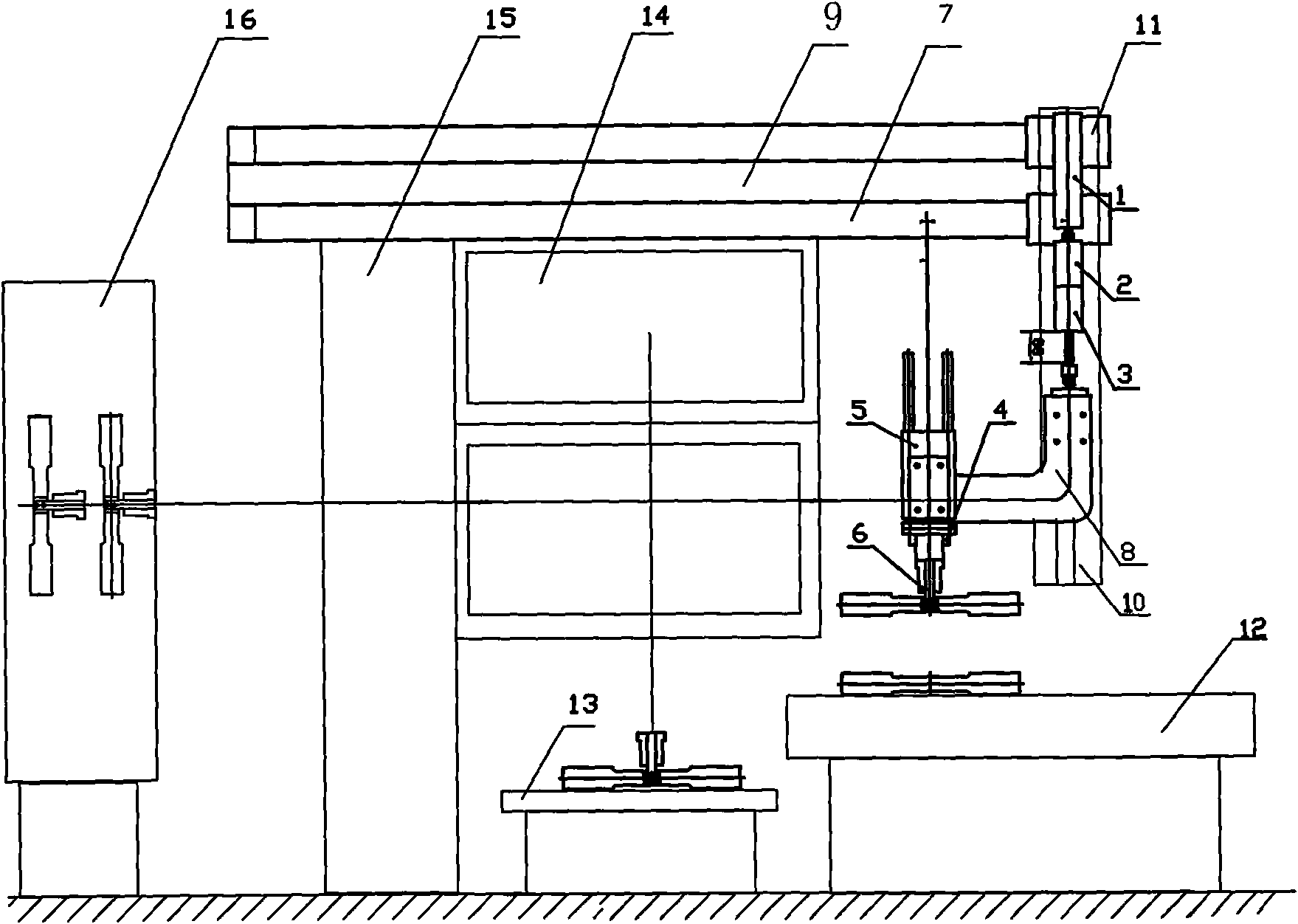

[0038] The side gantry type automatic loading and unloading manipulator is 3025mm long, 881mm thick and 2469mm high. It consists of a frame (9), a linear guide rail (10), a support plate (11), a sample support (12), a sample detector (13), an electronic control box (14), and a column (15). The bottom left and right sides of frame (9) are respectively provided with column (15), and the effect of column (15) is support frame (9), linear guide rail (10), support plate (11) and 7 cylinders. The electronic control box (14) is located between the two columns (15). The sample support (12) is a rotating disc, and the loading and unloading and discarding samples are placed on the rotating disc of the sample support (12). The electric cylinder (7) is fixed on the frame (9; the electric cylinder (7) and the thin air cylinder A (1) are respectively f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com