Automatic loading machine for pipes

An automatic feeding and feeding technology, which is applied to the attachment of shearing machines, metal processing, shearing devices, etc., can solve the problems of increased production costs, low production efficiency, and high operating intensity, so as to reduce waste and facilitate operation , the effect of reducing the operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation methods, structural diagrams, and features provided according to the present invention are described in detail as follows:

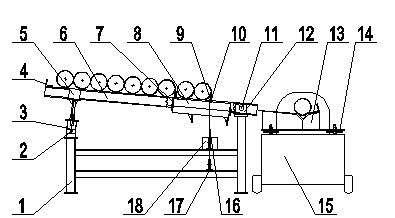

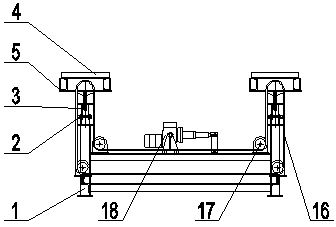

[0023] like Figure 1-Figure 7 As shown, an automatic pipe feeding machine includes two parts: an automatic feeding system and a receiving system.

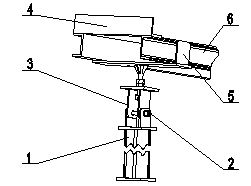

[0024] The automatic feeding system such as figure 1 , figure 2 As shown, there is a steel structure base frame 1 placed on the side of the feed end of the pipe cutting machine. The base frame 1 is connected coaxially with the swing frame 3 through a bolt assembly 2 or a cotter pin and a pin shaft; the adjustable bracket 5 It is a groove-shaped frame body welded by steel, with a screw and a nut below it, and the adjustable bracket 5 is connected with the swing frame 3 through the screw and the nut (see image 3 ); the front end of the swing bracket 6 is stuck in the U-shaped slot 12 provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com