Packaging process for tire pressure monitoring device

A technology of tire pressure monitoring and packaging technology, which is applied to tire measurement, measurement devices, tire parts, etc., and can solve problems such as difficulty in achieving integration and large volume of tire pressure monitoring devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

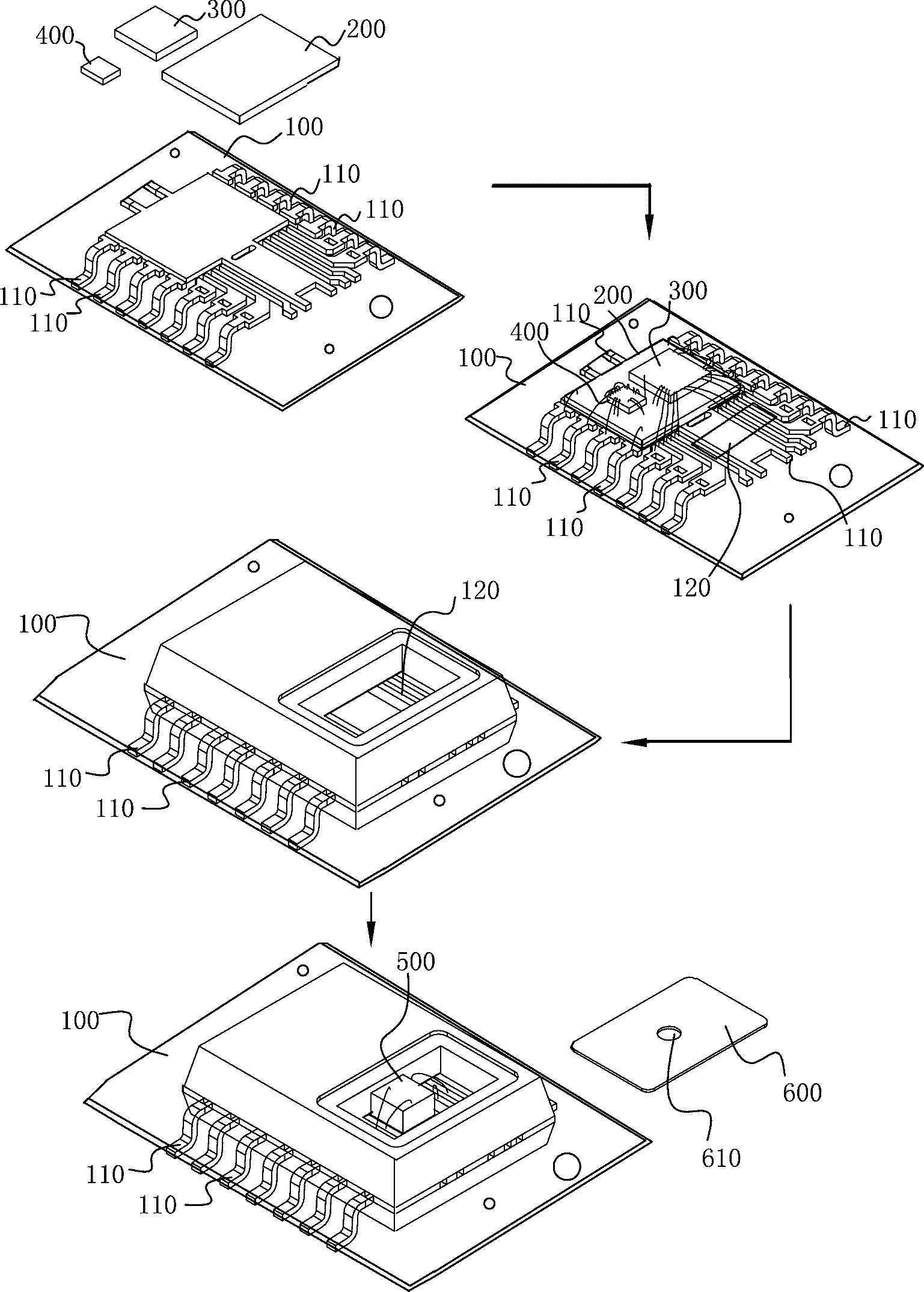

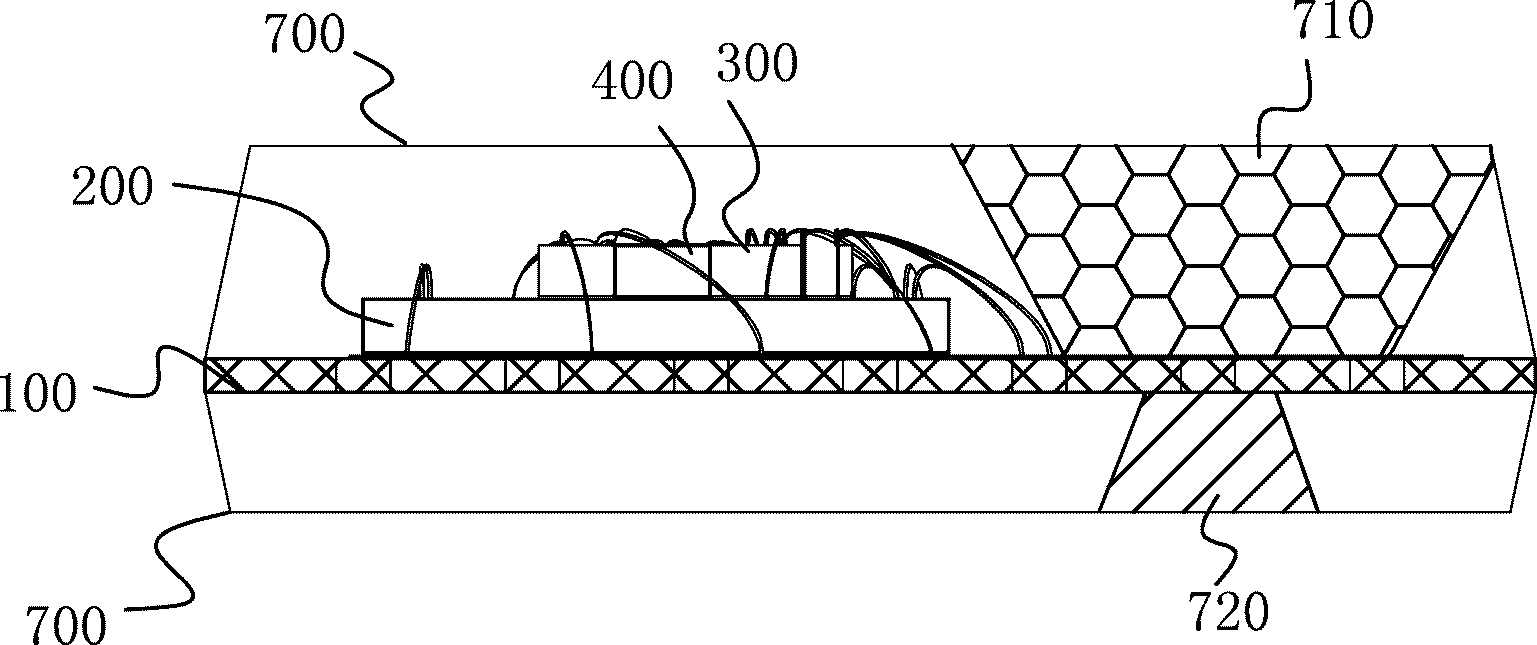

[0043] A packaging process for a tire pressure monitoring device, such as figure 1 , figure 2 As shown, first prepare the following raw materials: metal lead frame 100, PCB board 200, MCU chip 300, RF chip 400, pressure sensor chip 500 and required packaging glue. The metal lead frame is provided with metal pins 110 , and the circuit layout is on the PCB board 200 .

[0044] After the above raw materials are prepared, the packaging process of the tire pressure monitoring device is carried out, which specifically includes the following steps:

[0045] A. Insulate and fix the PCB board 200 on the upper surface of the metal lead frame 100 .

[0046] B. Mount the MCU chip 300 and the RF chip 400 on the upper surface of the PCB 200 . The positions of the MCU chip 300 and the RF chip 400 on the upper surface of the PCB 200 are designed according to specific products. When mounting, the MCU chip 300 can be mounted first, and then the RF chip 400 can be mounted, or the RF chip 400...

Embodiment 2

[0059] A packaging process for a tire pressure monitoring device, such as figure 1 , figure 2 As shown, first prepare the following raw materials: metal lead frame 100, PCB board 200, MCU chip 300, RF chip 400, pressure sensor chip 500 and required packaging glue. The metal lead frame is provided with metal pins 110, and the PCB board 200 is provided with a circuit layout.

[0060] Specifically include the following steps:

[0061] A. Insulate and fix the PCB board 200 on the upper surface of the metal lead frame 100 .

[0062] B. Mount the MCU chip 300 and the RF chip 400 on the upper surface of the PCB 200 . The positions of the MCU chip 300 and the RF chip 400 on the upper surface of the PCB 200 are designed according to specific products. When mounting, the MCU chip 300 can be mounted first, and then the RF chip 400 can be mounted, or the RF chip 400 can be mounted first, and then the MCU chip 300 can be mounted.

[0063] C, MCU chip 300, RF chip 400 are connected wit...

Embodiment 3

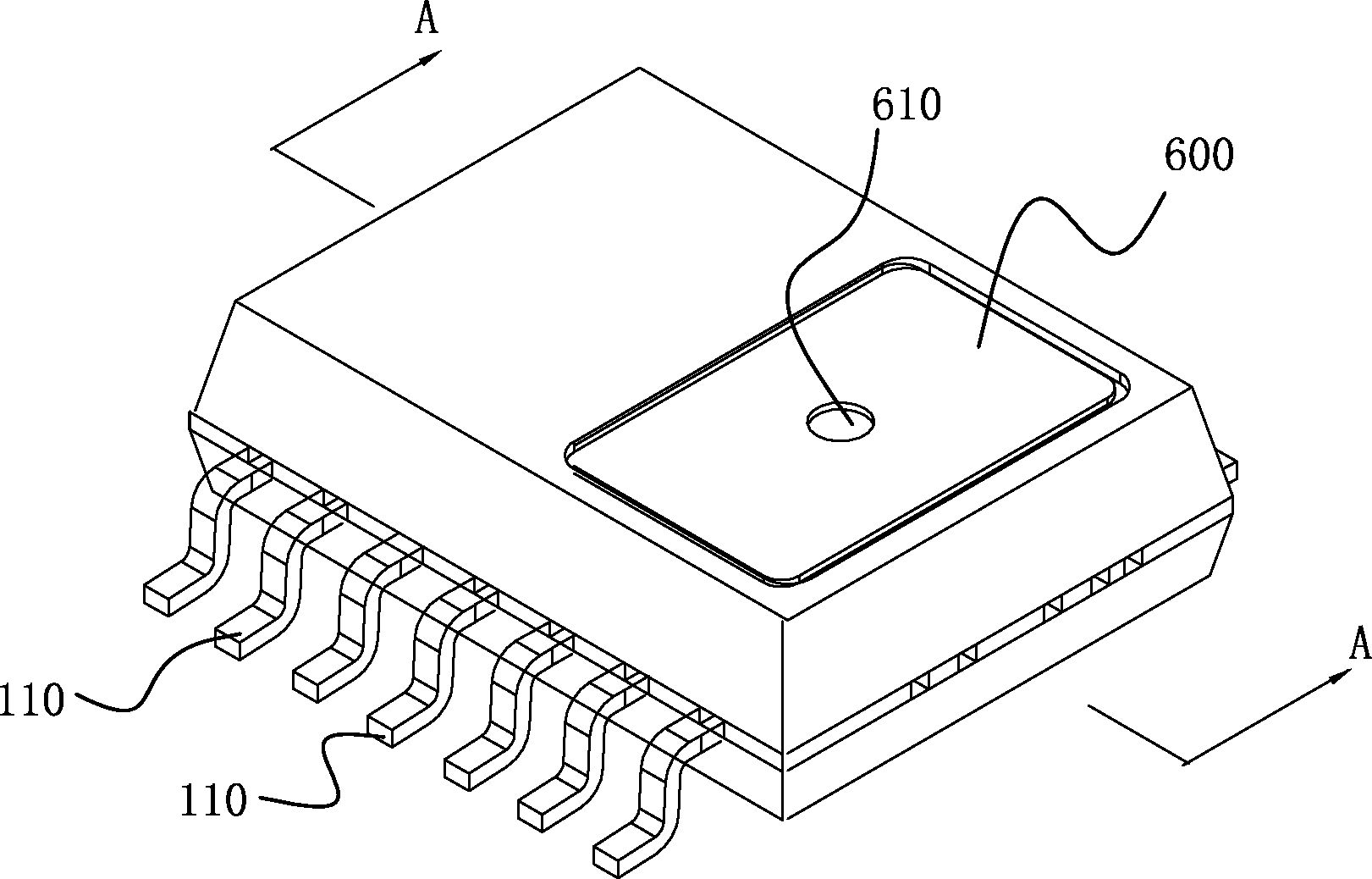

[0076] Through the packaging process of a tire pressure monitoring device of the present invention, a tire pressure monitoring device suitable for a tire pressure monitoring system (TPMS) is prepared, such as Figure 5 , Figure 6 shown.

[0077] The shape of the tire pressure monitoring device is as follows: Figure 5 As shown, from the appearance, it has a shell, a metal cover 600 on the upper part of the shell, and exposed metal lead frame 100 pins. The metal cover 600 is provided with a through hole 610 .

[0078] The functions of each pin of the tire pressure monitoring device are shown in Table 1.

[0079] Table 1 Function table of each pin

[0080] pin

name

Function

1

PAOUT

Power amplifier output

2

IN2

Low frequency negative input

3

IN1

Low Frequency Positioning Input

4

GND

system grounding point

5

V2P

Sensor negative input 2

6

V2VSS

Negative Sensor Stimulation 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com