Vacuum coating machine

A technology of vacuum coating machine and coating chamber, which is applied in vacuum evaporation coating, sputtering coating, ion implantation coating, etc., which can solve the problems of low production efficiency, large labor cost, and increased labor consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

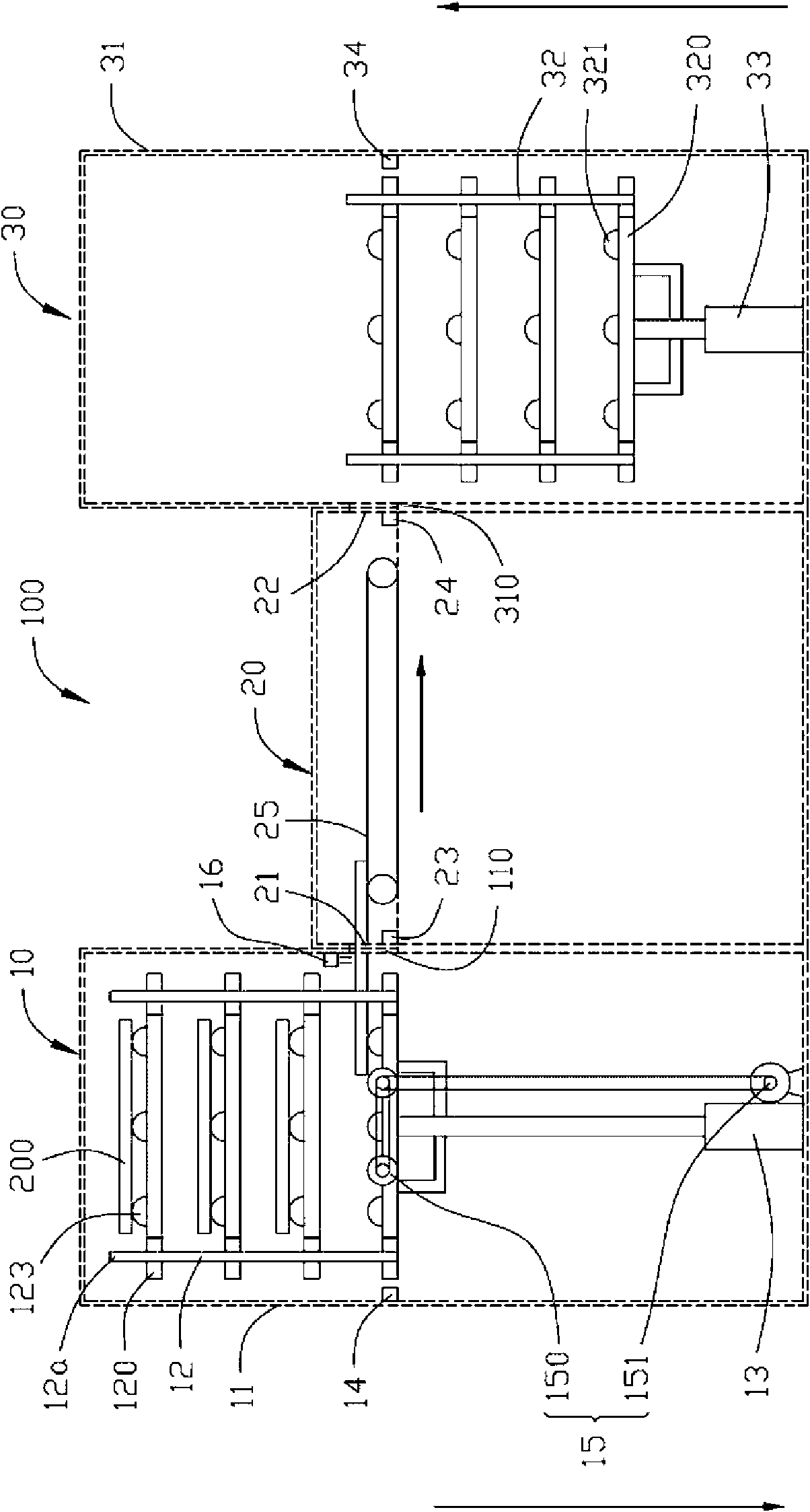

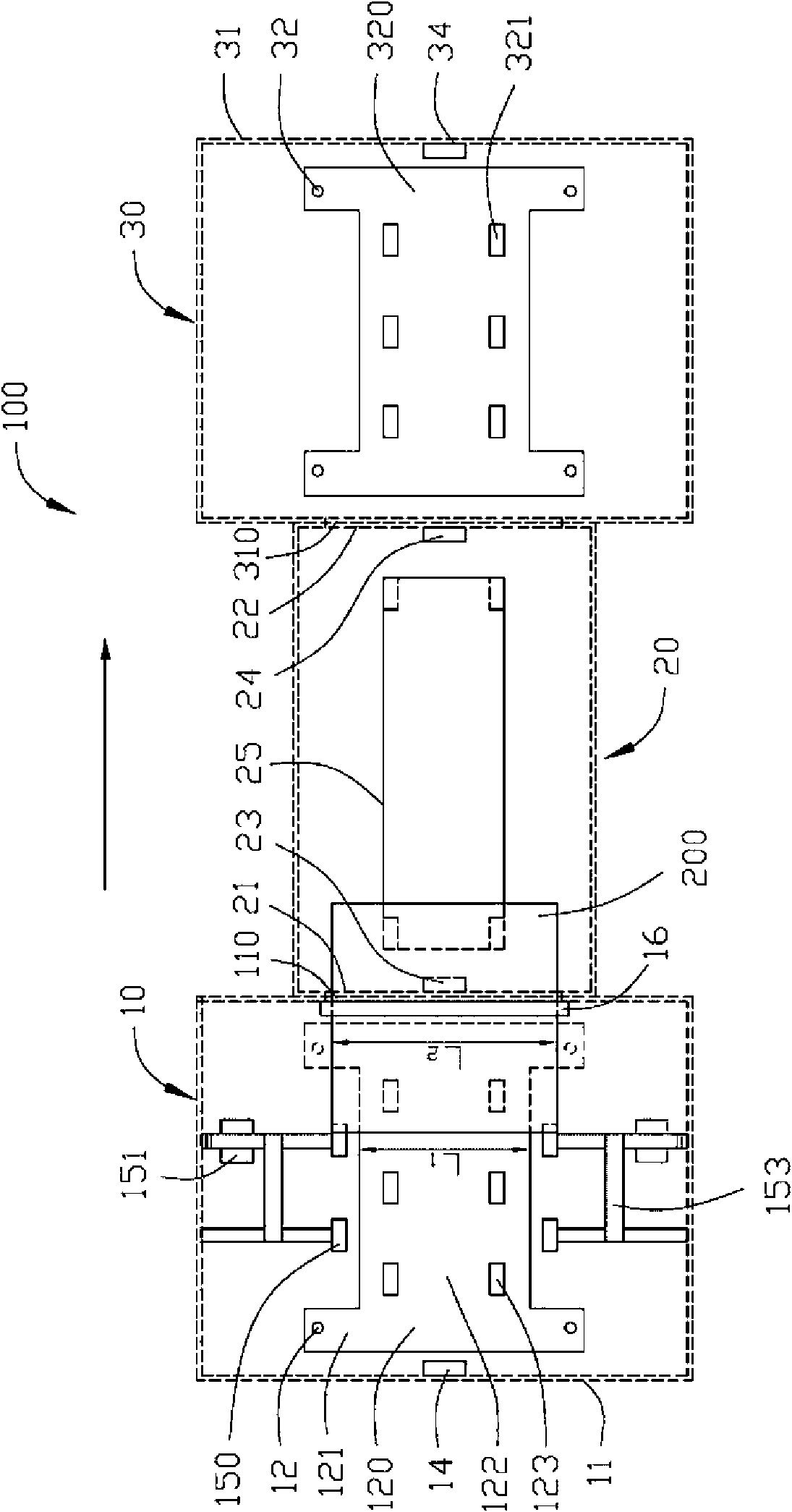

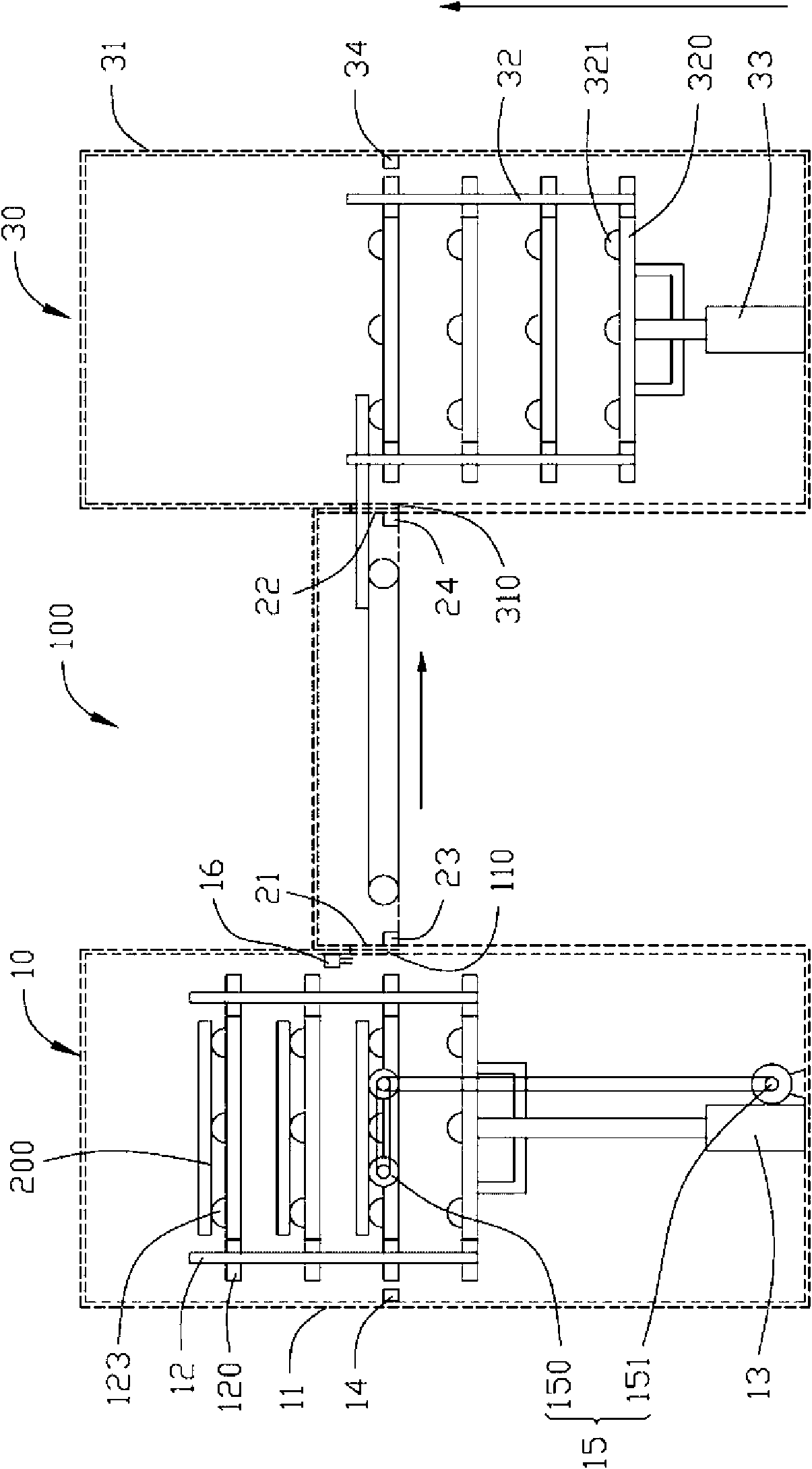

[0009] See figure 1 and figure 2 , a vacuum coating machine 100 provided in an embodiment of the present invention, the vacuum coating machine 100 is provided with a loading chamber 10 , a coating chamber 20 and an unloading chamber 30 sequentially from one end to the other end. The two ends of the coating chamber 20 are provided with a material inlet 21 and a material outlet 22 . The loading chamber 10 is connected to the material inlet 21 . The unloading chamber 30 is connected with the discharge port 22 . A first sensor 23 , a second sensor 24 and a conveyor belt 25 are installed in the coating chamber 20 , and the first sensor 23 is used to sense whether the carrier plate 200 carrying workpieces to be coated enters the coating chamber 20 completely. The first sensor 23 can be a position sensor or a displacement sensor. In this embodiment, the first sensor 23 is a position sensor. When the first sensor 23 senses that the carrier plate 200 has completely entered the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com