Dimension automatic detection device and method of piston rod

A technology of automatic detection device and piston rod, applied in measurement devices, optical devices, instruments, etc., can solve problems such as hidden dangers in quality and safety, large manual operation errors, low labor efficiency, etc., and achieve high work efficiency and error rate. Low, fast detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

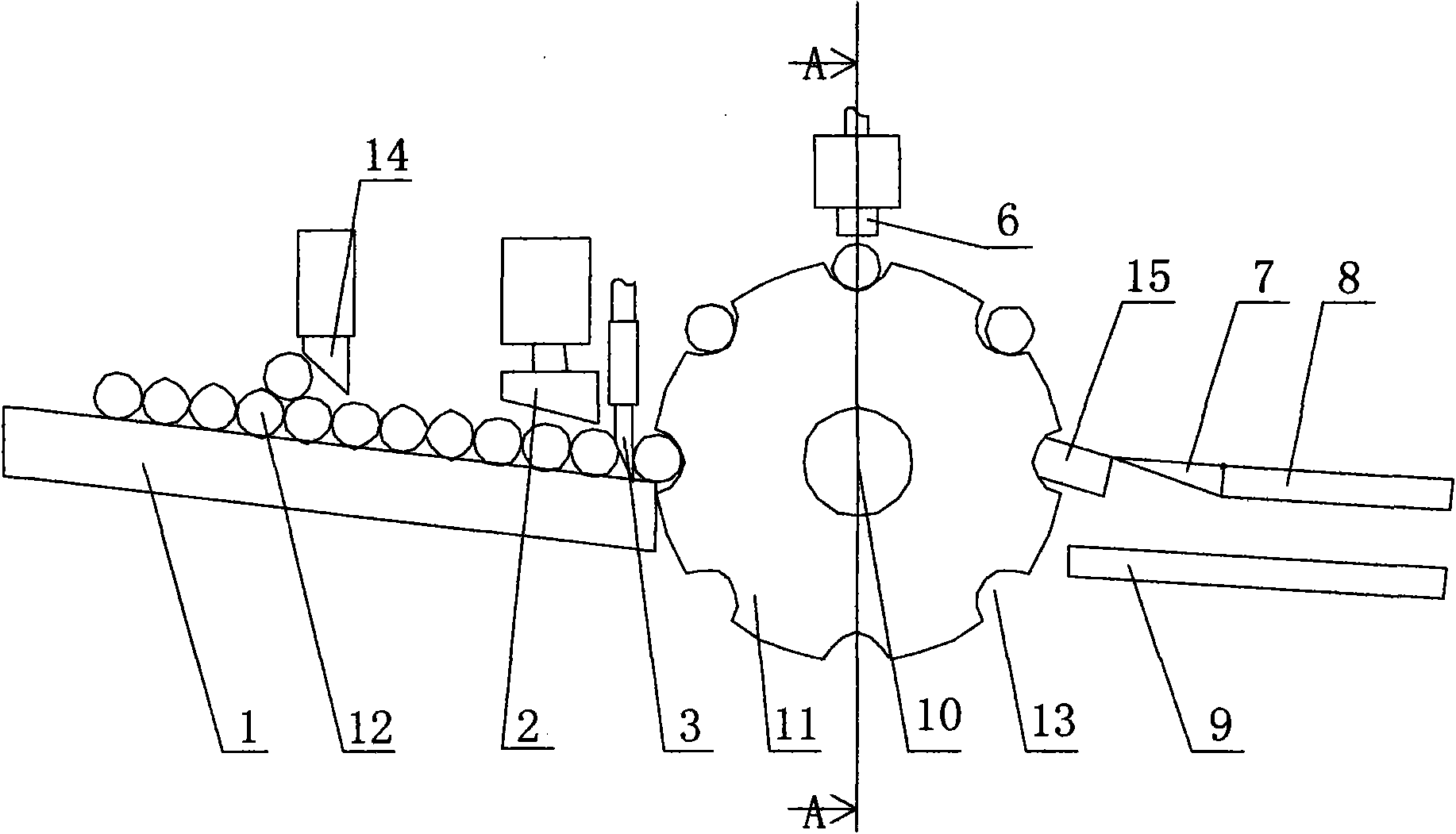

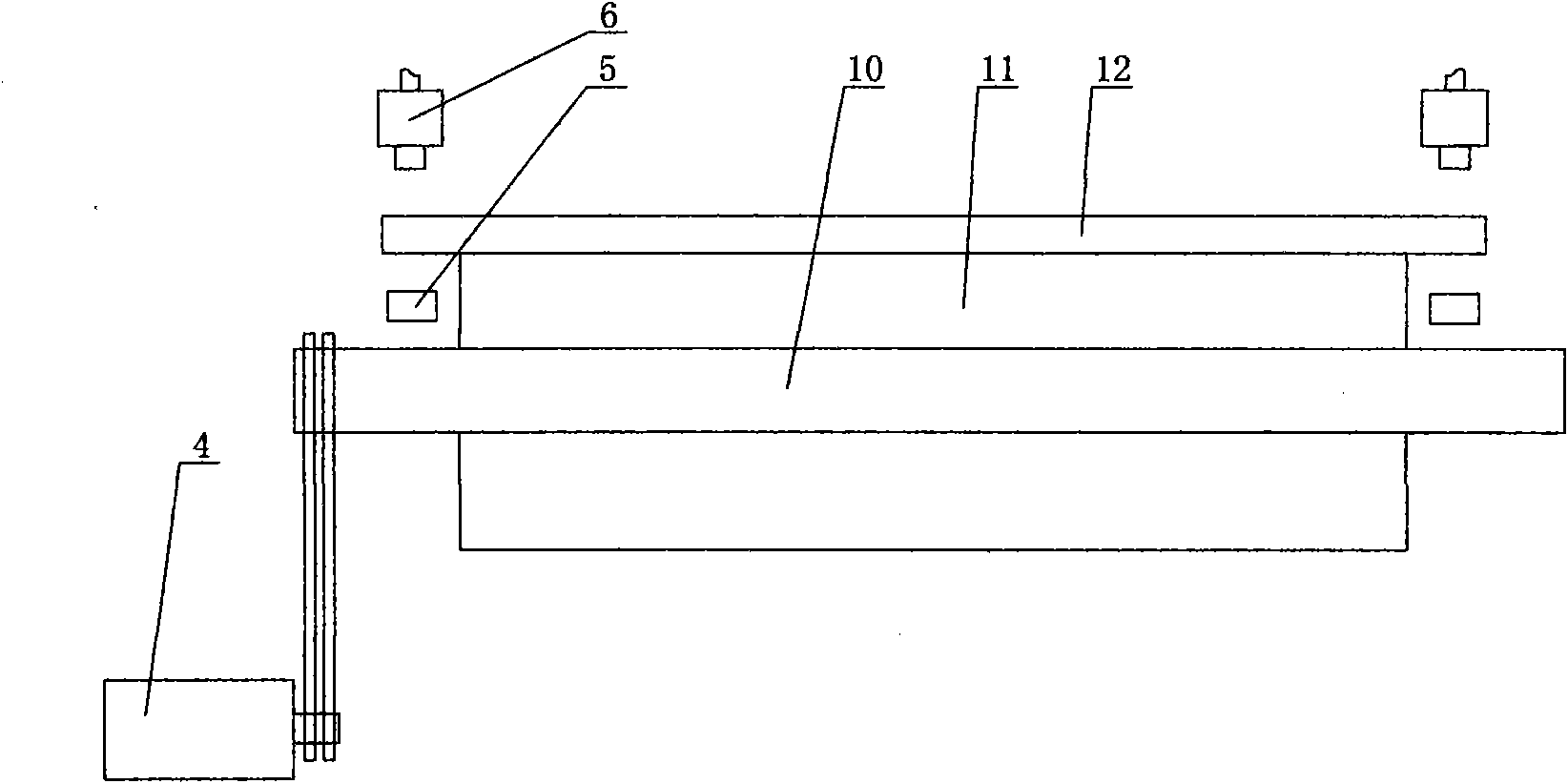

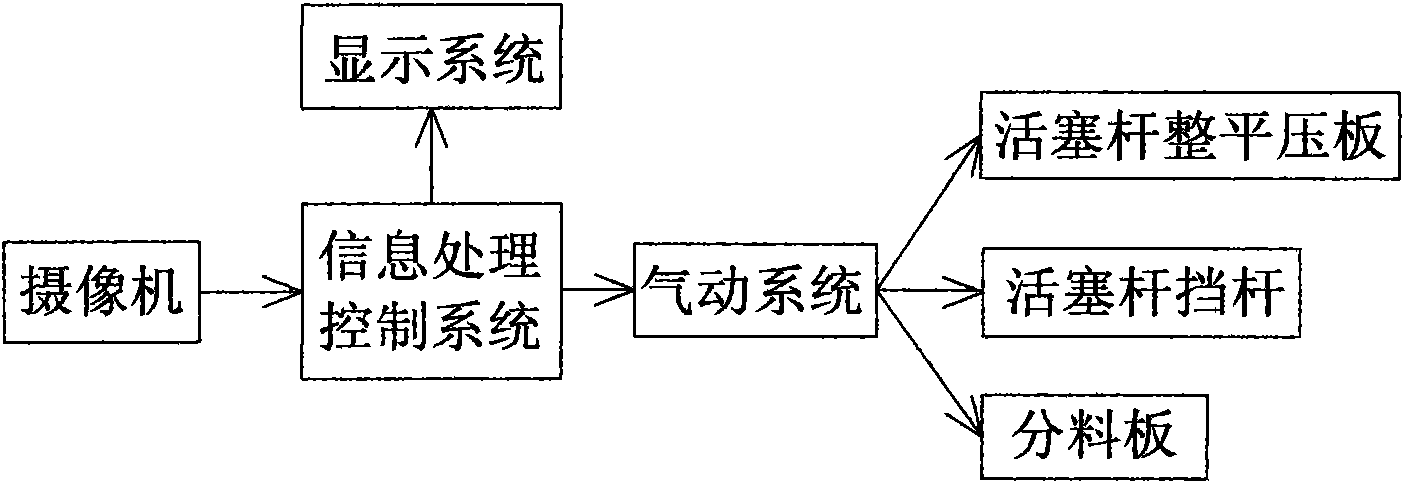

[0016] An automatic detection device for piston rod size, comprising a body, a feeding mechanism arranged on the body, a transmission detection mechanism, a material distribution mechanism and a feeding mechanism, the feeding mechanism includes an inclined feeding plate 1, and a feeding mechanism The upper part of the plate 1 is provided with a liftable piston rod leveling plate 2 connected with the pneumatic system. The leveling plate 2 is used to flatten the piston rods to make them evenly arranged. The feeding side of the piston rod leveling plate 2 is set There is a piston rod limit stopper 14, the bottom of the stopper 14 is a slope, and the multi-layer piston rods are flattened into one layer, and the end of the feeding plate 1 is provided with a liftable piston rod stopper connected with the pneumatic system. Rod 3, the described piston rod retaining rod 3 gradually becomes thinner from top to bottom, and can flexibly separate adjacent piston rods; the transmission detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com