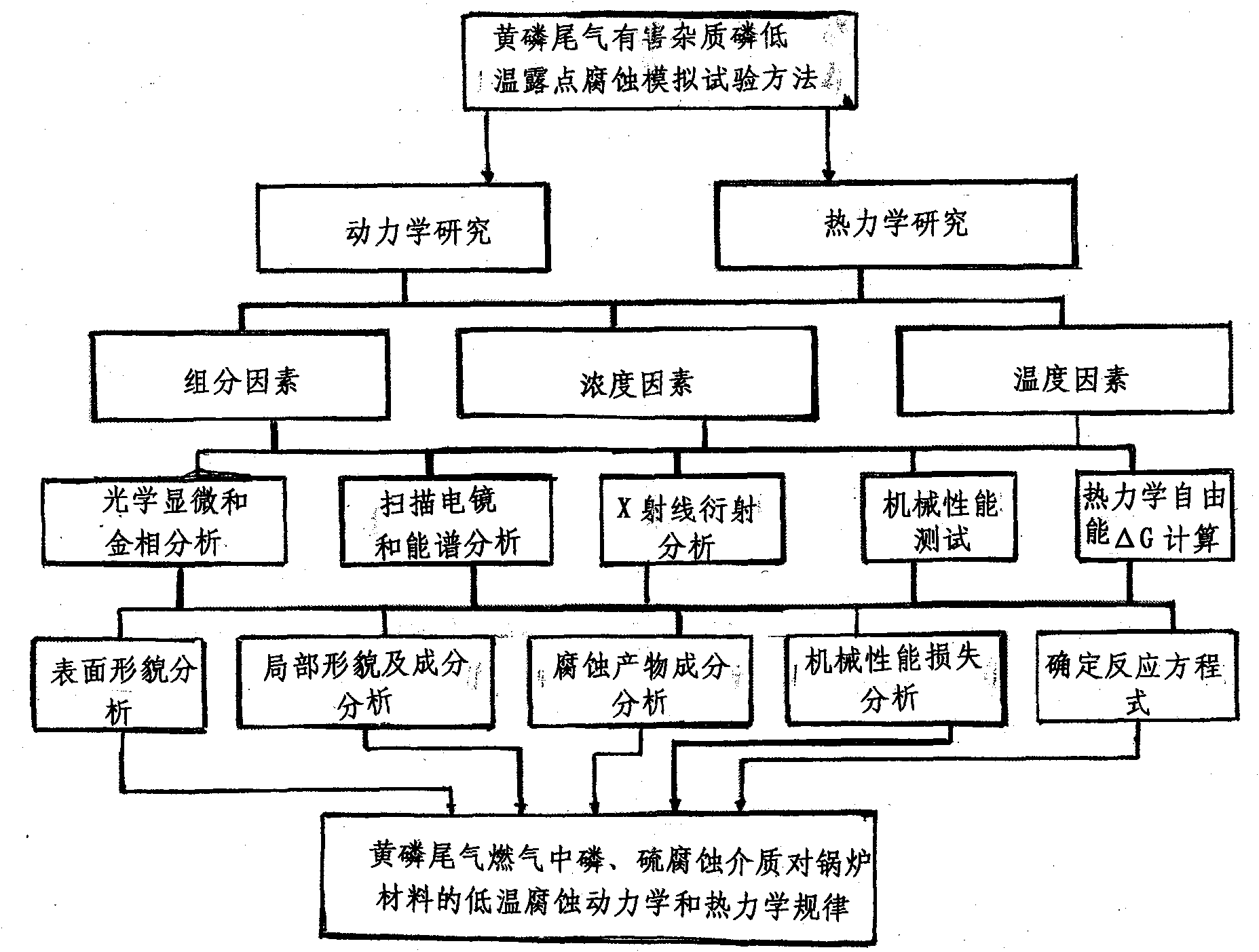

Low-temperature dew point corrosion experiment method for phosphorus in yellow phosphorus tail gas on boiler material and device thereof

A yellow phosphorus tail gas and dew point corrosion technology, which is applied in the fields of weather resistance/light resistance/corrosion resistance, measuring devices, and analysis materials, can solve the problems of failure to recycle boiler fuel, reduce boiler life, and low-temperature dew point corrosion. Avoid unstable exhaust gas volume, good use stability and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

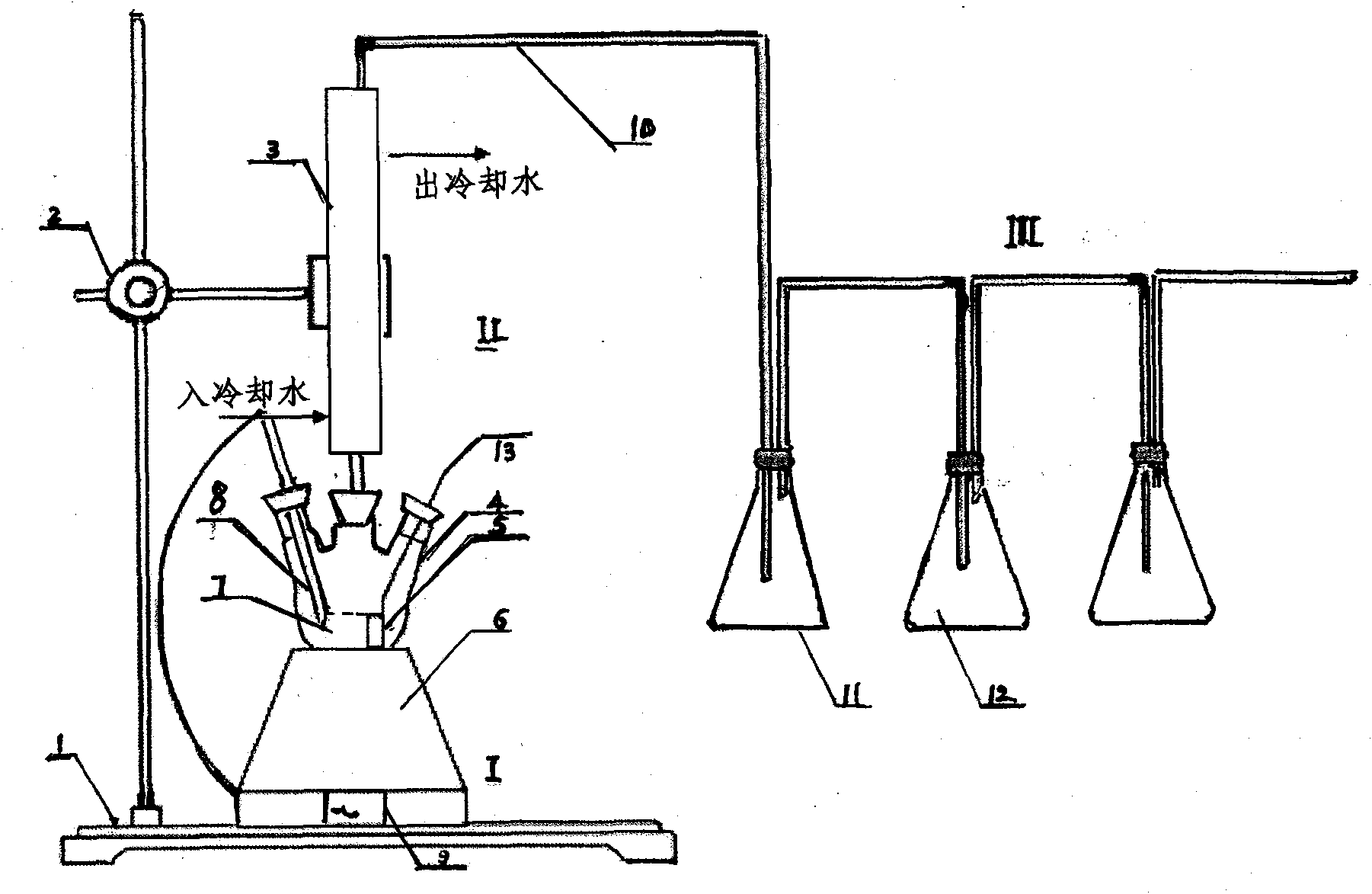

Method used

Image

Examples

Embodiment 1

[0020]Example 1 selects 20g and 304 commonly used boiler materials, adopts the above method, tests the concentration of phosphoric acid at 30%, 60%, and 85%, and tests the dew point corrosion resistance of the two materials at 40°C, 80°C, and 120°C. The chemical curve research shows that the material 304 has considerable corrosion resistance compared with 20g, and the corrosion of the material increases with the increase of temperature and concentration, but the influence of temperature on material corrosion is more obvious than that of phosphoric acid concentration, and the surface corrosion morphology analysis It shows that the chemical composition of the material itself has a great influence on the corrosion degree. The corrosion resistance of 304 is better than that of 20g because the 304 material contains two corrosion-resistant materials, Cr and Ni, and their simultaneous presence greatly improves the phosphoric acid dew point of 304 stainless steel. Corrosion performance...

Embodiment 2

[0021] Embodiment 2 This experimental method is also applicable to the research of the sulfuric acid dew point corrosion resistance of materials. In order to check the sulfuric acid dew point corrosion resistance of S TEN3 steel and CRIA steel, this method is adopted, and the experimental sulfuric acid concentration is 30%, 60%, and 85%. The temperature is 60°C, 80°C, and 110°C, and the corrosion kinetics curve research shows that S-TEN 3 Steel and CRIA steel have excellent sulfuric acid dew point corrosion resistance. It is 4 to 12 times higher than ordinary carbon steel, of which S-TEN 3 More superior, the analysis of its corrosion mechanism shows that adding an appropriate amount of alloying elements Sb or Ti on the basis of chrome-copper steel is beneficial to improving the sulfuric acid dew point corrosion resistance of S-TEN3 and CRIA, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com