High-voltage multi-point testing equipment and method with main and auxiliary steps

A multi-point testing, high-voltage technology, applied in the direction of testing dielectric strength, measuring electricity, measuring devices, etc., can solve problems that affect the life of contact points, missing, arcing, etc., and achieve the effect of avoiding test errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

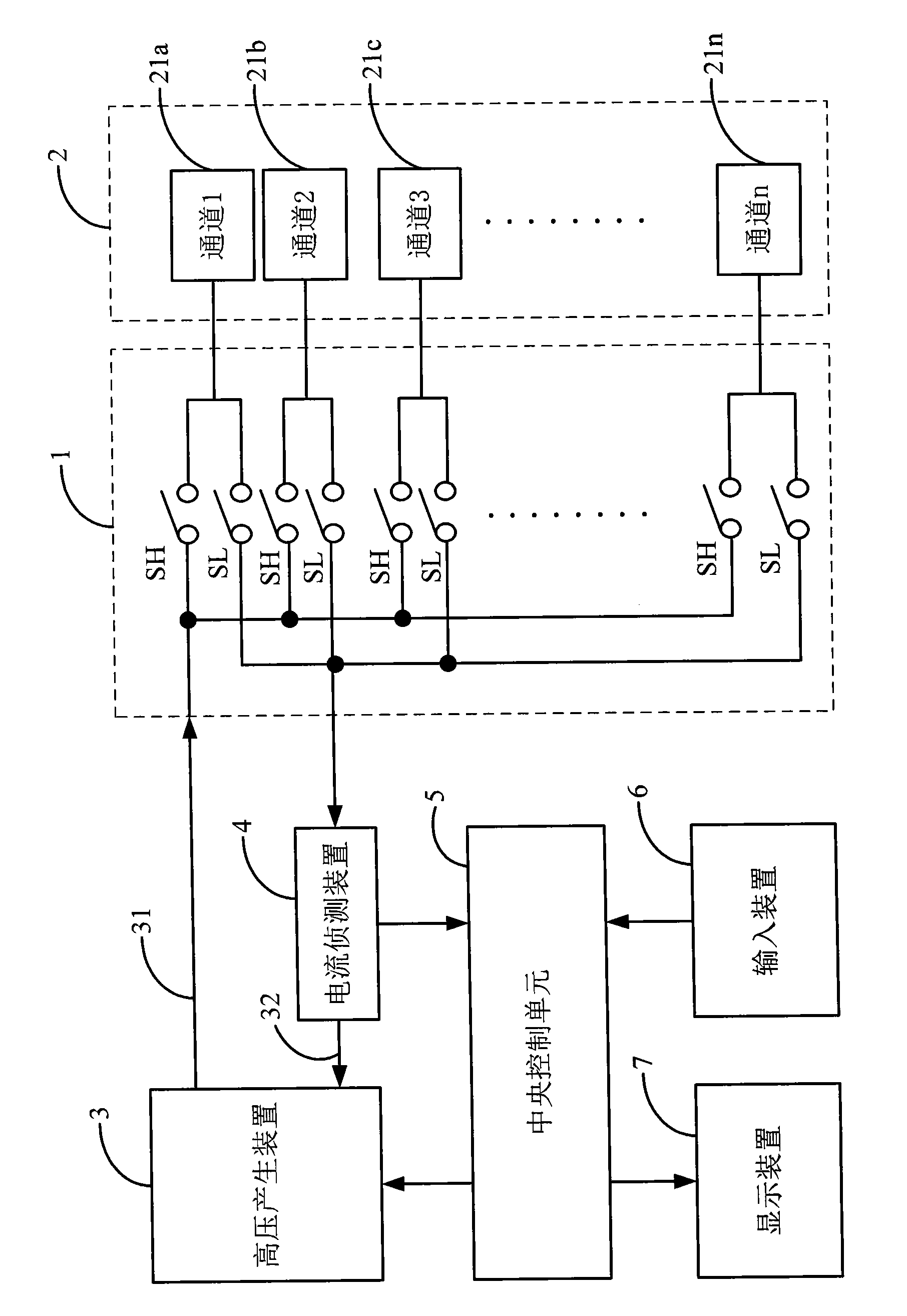

[0030] see figure 1 Shown, be the block diagram of tool main high voltage multi-point test equipment and method provided by the present invention, mainly comprise:

[0031] A high / low voltage switching device 1, the high / low voltage switching device 1 includes an array of high voltage switches SH and several low voltage switches SL, so that the voltage output mode of the high / low voltage switching device 1 is that of each group of high voltage switches SH and low voltage switches SL switch on and off;

[0032] A test channel group 2, the test channel group 2 includes multiple groups of test channels 21a-21n, each group of test channels 21a-21n is connected to a group of high-voltage switches SH and a low-voltage switch SL of the high / low voltage switching device 1, When the high-voltage switch SH is in the conduction state (ON), the low-voltage switch SL is in the non-conduction state (OFF), so that the single test channels 21a-21n can only selectively output high-voltage or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com