Low-stress solar assembly and manufacture method thereof

A technology of solar modules and manufacturing methods, applied in the direction of final product manufacturing, sustainable manufacturing/processing, electrical components, etc., can solve the problems of high fragmentation rate of solar modules, large thermal stress of solar modules, and high cost of use, so as to improve consistency and pass rate, reduce thermal stress, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific drawings and embodiments.

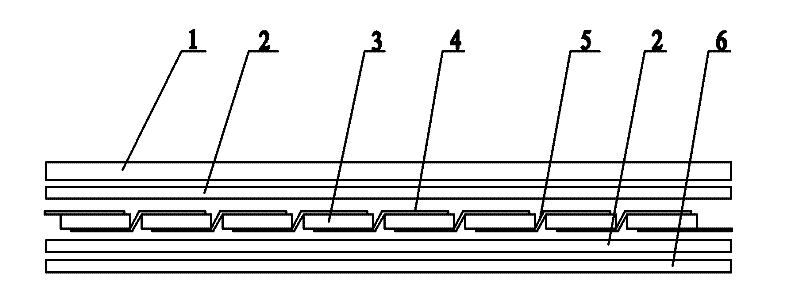

[0014] Such as figure 1 with image 3 As shown: the present invention includes a glass plate 1 , an adhesive 2 , a battery sheet 3 , a welding ribbon 4 , a bend 5 and a back film 6 .

[0015] Such as figure 1 As shown: the solar module includes a glass plate 1 and a back film 6, and several battery pieces 3 are arranged between the glass plate 1 and the back film 6, and the battery pieces 3 are connected as a whole by welding ribbons 4 to form a battery piece Components; the battery chip component is fixed to the glass plate 1 and the back film 6 through the adhesive 2 respectively. A bend 5 is provided in the central area of the solder ribbon 4, and the bend 5 is located between adjacent battery sheets 3, and the height of the bend 5 is 150 μm-300 μm. The bend 5 is formed by bending at the central area of the welding ribbon 4, so as to provide cushioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com