A method for preparing stainless steel/pipeline steel composite plates for oil and gas transportation pipelines

A technology for transportation pipelines and stainless steel plates, which is applied in the field of composite material preparation for oil and gas pipelines. It can solve the problems that the length of the tube blank can only be limited to a short range, the oil and gas medium is flammable, and the bonding strength is low, so as to ensure the uniformity of bonding. , Improve the utilization rate, the effect of excellent strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In this embodiment, the preparation of stainless steel / pipeline steel composite plates for oil and gas transportation pipelines includes the following steps:

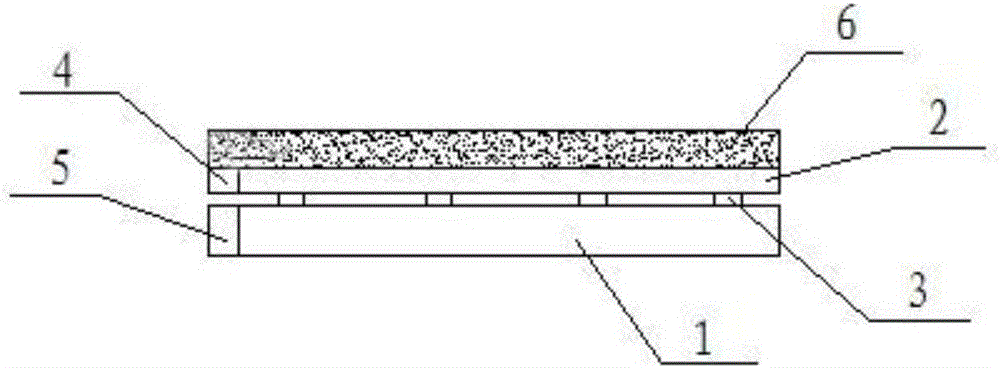

[0027] Step 1. Use arc welding to weld the metal block 5 at the middle position of the long side of the base pipeline steel plate 1, and use argon arc welding to weld the metal plate 4 at the middle position of the long side of the multilayer stainless steel plate 2, such as figure 1 As shown; the base-level pipeline steel plate 1 is an X65 pipeline steel plate, the detection results of the impact energy of the base-level pipeline steel plate 1 at 0°C are 298J, 298J and 280J respectively, the length of the base-level pipeline steel plate 1 is 3000mm, the width is 2100mm, and the thickness is 58mm, the material of the metal block 5 is the same as that of the base pipeline steel plate 1, the length of the metal block 5 is 100mm, the width is 50mm, and the thickness is the same as that of the base steel plate 1; the ...

Embodiment 2

[0038] In this embodiment, the preparation of stainless steel / pipeline steel composite plates for oil and gas transportation pipelines includes the following steps:

[0039] Step 1. Use arc welding to weld the metal block 5 at the middle position of the long side of the base pipeline steel plate 1, and use argon arc welding to weld the metal plate 4 at the middle position of the long side of the multilayer stainless steel plate 2, such as figure 1 As shown; the base-level pipeline steel plate 1 is an L390 pipeline steel plate, the detection results of the impact energy of the base-level pipeline steel plate 1 at 0°C are 210J, 198J and 246J respectively, the length of the base-level pipeline steel plate 1 is 2700mm, the width is 500mm, and the thickness is 120mm, the material of the metal block 5 is the same as that of the base pipeline steel plate 1, the length of the metal block 5 is 100mm, the width is 50mm, and the thickness is the same as that of the base steel plate 1; the...

Embodiment 3

[0048] In this embodiment, the preparation of stainless steel / pipeline steel composite plates for oil and gas transportation pipelines includes the following steps:

[0049] Step 1. Use arc welding to weld the metal block 5 at the middle position of the long side of the base pipeline steel plate 1, and use argon arc welding to weld the metal plate 4 at the middle position of the long side of the multilayer stainless steel plate 2, such as figure 1 As shown; the base-level pipeline steel plate 1 is an L450 pipeline steel plate, the detection results of the impact energy of the base-level pipeline steel plate 1 at 0°C are 282J, 298J and 298J respectively, the length of the base-level pipeline steel plate 1 is 3000mm, the width is 2680mm, and the thickness is 80mm, the material of the metal block 5 is the same as that of the base pipeline steel plate 1, the length of the metal block 5 is 100mm, the width is 50mm, and the thickness is the same as that of the base steel plate 1; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com