Coarse-grain-free wrought aluminum alloy as well as preparation method and product thereof

A technology for deforming aluminum alloys and aluminum alloys, applied in the field of metal materials, can solve the problems of uneven material properties, tensile strength, elongation reduction, and corrosion resistance degradation, etc., to suppress the formation of coarse grains, improve matrix strength, Effect of suppressing grain coarsening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

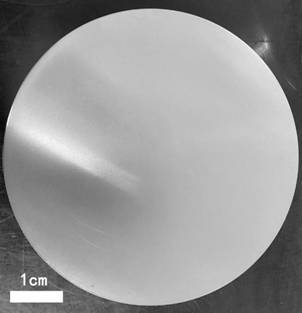

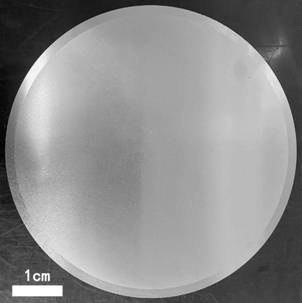

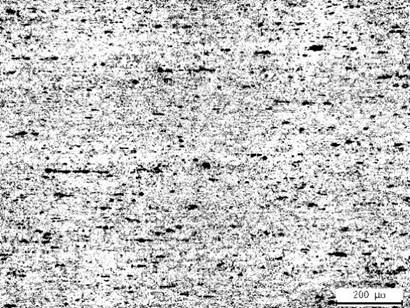

Image

Examples

preparation example Construction

[0065] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0066] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

[0067] The preparation materials used in the following examples are as follows:

[0068] Pure metal aluminum is Al99.993, and the element content requirements meet the requirements of GB / T 8644-2000;

Embodiment 1

[0081] A method for preparing a deformed aluminum alloy without coarse grains of the present invention comprises the following steps:

[0082] 1) Weigh the raw materials according to the obtained deformed aluminum alloy without coarse grains containing the following elements by weight percentage (the raw materials are as above), Zn: 4.7%, Mg: 1.1%, Cu: 1.1%, V: 0.6%, Zr : 0.07%, Li: 0.07%, Ti: 0.07%, Mn: 0.01%, Hf: 0.09%, B: 0.01%, Be: 0.007%, impurity elements: 0.08% (specifically Fe: 0.03%, Si: 0.02 %, Sn: 0.01%, Pb: 0.02%), the balance is Al;

[0083] 2) Melt and put in pure aluminum ingots, pure zinc ingots, pure copper ingots, Al-V master alloys, Al-Zr master alloys, Al-Ti master alloys, Al-B master alloys, Al-Mn master alloys, Al- For Hf master alloy, heat the furnace to raise the temperature of the furnace to 720°C, keep it warm for 1 hour, and stir for 30 minutes;

[0084] 3) Lower the temperature to lower the temperature of the furnace to 680°C, add pure magnesium i...

Embodiment 2

[0090] A method for preparing a deformed aluminum alloy without coarse grains of the present invention comprises the following steps:

[0091] 1) Weigh the raw materials according to the obtained deformed aluminum alloy without coarse grains containing the following elements by weight percentage (the raw materials are as above), Zn: 5.3%, Mg: 1.3%, Cu: 0.9%, V: 0.5%, Zr : 0.10%, Li: 0.05%, Ti: 0.09%, Mn: 0.02%, Hf: 0.11%, B: 0.02%, Be: 0.01%, impurity elements: 0.05% (specifically Fe: 0.01%, Si: 0.01 %, Sn: 0.01%, Pb: 0.02%), the balance is Al;

[0092] 2) Melt and put in pure aluminum ingots, pure zinc ingots, pure copper ingots, Al-V master alloys, Al-Zr master alloys, Al-Ti master alloys, Al-B master alloys, Al-Mn master alloys, Al- For Hf master alloy, heat the furnace to raise the temperature of the furnace to 730°C, keep it warm for 1.5h, and stir for 20min;

[0093] 3) Lower the temperature to lower the temperature of the furnace to 695°C, add pure magnesium ingots, A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| fatigue bending times | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com