Preparation method for fuel cell compound proton exchange membrane enhanced by using SiO2 three-dimensional ultra-thin membrane

A proton exchange membrane and fuel cell technology, applied in fuel cell parts, fuel cells, battery pack parts, etc., can solve the problems of unsuitable assembly application, decreased mechanical strength, poor continuity, etc. Stability issues, high dimensional stability, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

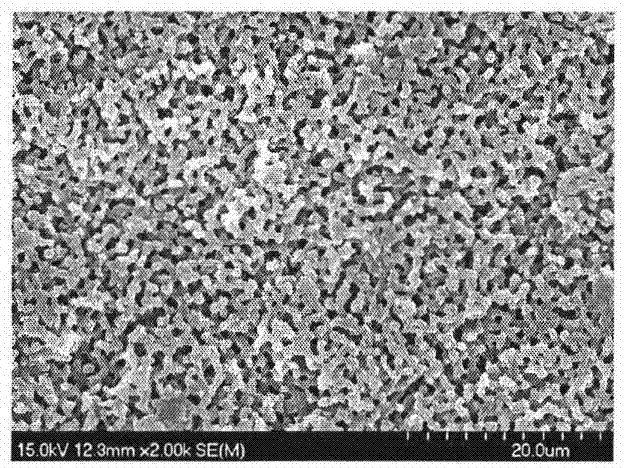

[0035] Step 1: 6 grams of epoxy resin and 1.5 grams of diethylenetriamine were dissolved in a mixed medium of 15 grams of polyethylene glycol 1000 and 3 grams of polyethylene glycol 2000, and defoamed, and then the solution was cast on a stainless steel plate, static Placed at 55°C for 5 hours, the solution phase separated, and the gel solidified into a white epoxy resin nascent membrane. The nascent membrane was immersed in water to remove polyethylene glycol to obtain an epoxy resin microfiltration membrane with a structure such as figure 1 shown.

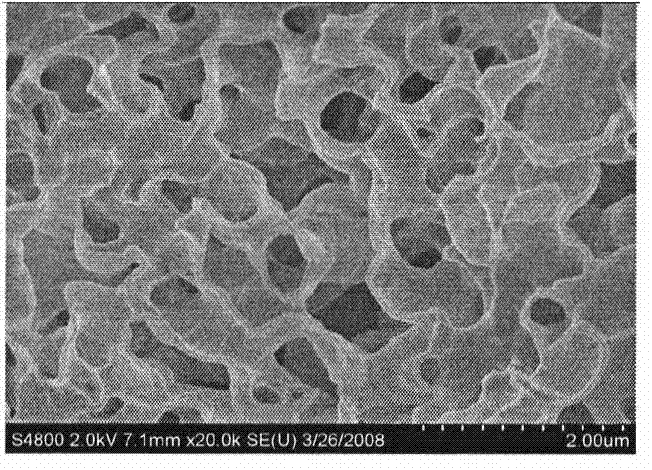

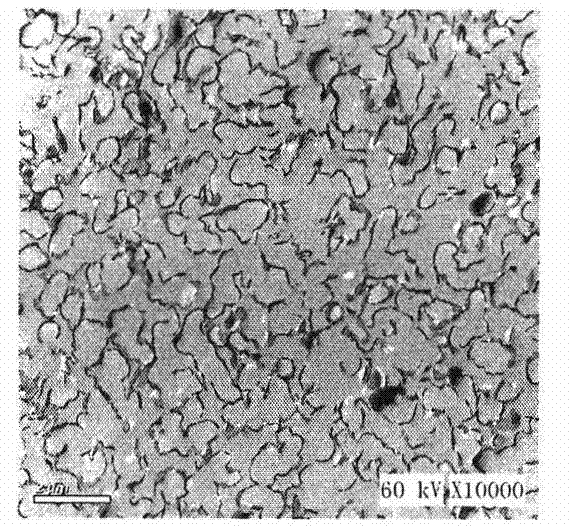

[0036] Step 2: Soak the epoxy resin microfiltration membrane with a three-dimensional skeleton structure in step 1 in tetraethyl orthosilicate for 2 hours, and then expose it to an ammonia atmosphere at 45°C for 16 hours. SiO produced by in situ hydrolysis in the pores of the resin microfiltration membrane template 2 Deposit on the surface of the template channel to form three-dimensional SiO 2 The continuous phase is coated w...

Embodiment 2

[0040] Step 1: Same as Step 1 of Example 1.

[0041] Step 2: Soak the epoxy resin microfiltration membrane in step 1 in tetraethyl orthosilicate for 2 hours, and then expose it to ammonia atmosphere at 45°C for 16 hours, and the epoxy resin microfiltration membrane In situ hydrolysis in the template pores, resulting in SiO 2 Deposit on the surface of the template channel to form three-dimensional SiO 2 The continuous phase is coated with a composite film of epoxy resin, dried for 4 hours to remove the generated ethanol and adsorbed ammonia water, then heated to 800°C in a muffle furnace, kept for 30 minutes, and calcined at a high temperature to remove the epoxy resin. SiO 2 Sintering and shaping, SiO coated on the surface of epoxy resin 2 can form a complete three-dimensional SiO 2 Ultra-thin microporous membrane.

[0042] Repeat the above steps once.

[0043] Step 3: SiO obtained in Step 2 2 Cast a certain amount of 5% Nafion solution on the microporous membrane, heat...

Embodiment 3

[0046] Step 1: Same as Step 1 of Example 1.

[0047] Step 2: Soak the epoxy resin microfiltration membrane in step 1 in tetraethyl orthosilicate / cyclohexylamine (mass ratio is 1: 1) for 2 hours, after that, expose in the ammoniacal liquor atmosphere of 45 ℃ for 16 hours, Tetraethyl orthosilicate was hydrolyzed in situ in the channels of the epoxy resin microfiltration membrane template to produce SiO 2 Deposit on the surface of the template channel to form three-dimensional SiO 2 The continuous phase is coated with a composite film of epoxy resin, dried for 5 hours to remove the generated ethanol and adsorbed ammonia water, etc., then heated to 800°C in a muffle furnace, kept for 30 minutes, and calcined at a high temperature to remove the epoxy resin. make SiO 2 Sintering and shaping, SiO coated on the surface of epoxy resin 2 can form a complete three-dimensional SiO 2 Ultra-thin microporous membrane.

[0048] Step 3: SiO obtained in Step 2 2 Cast a certain amount of 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com