Energy machine of electric energy circulating machine

A technology of motors and capabilities, applied in the direction of electrical components, electromechanical devices, etc., can solve problems such as centrifugal disintegration, small frictional resistance, and high material requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

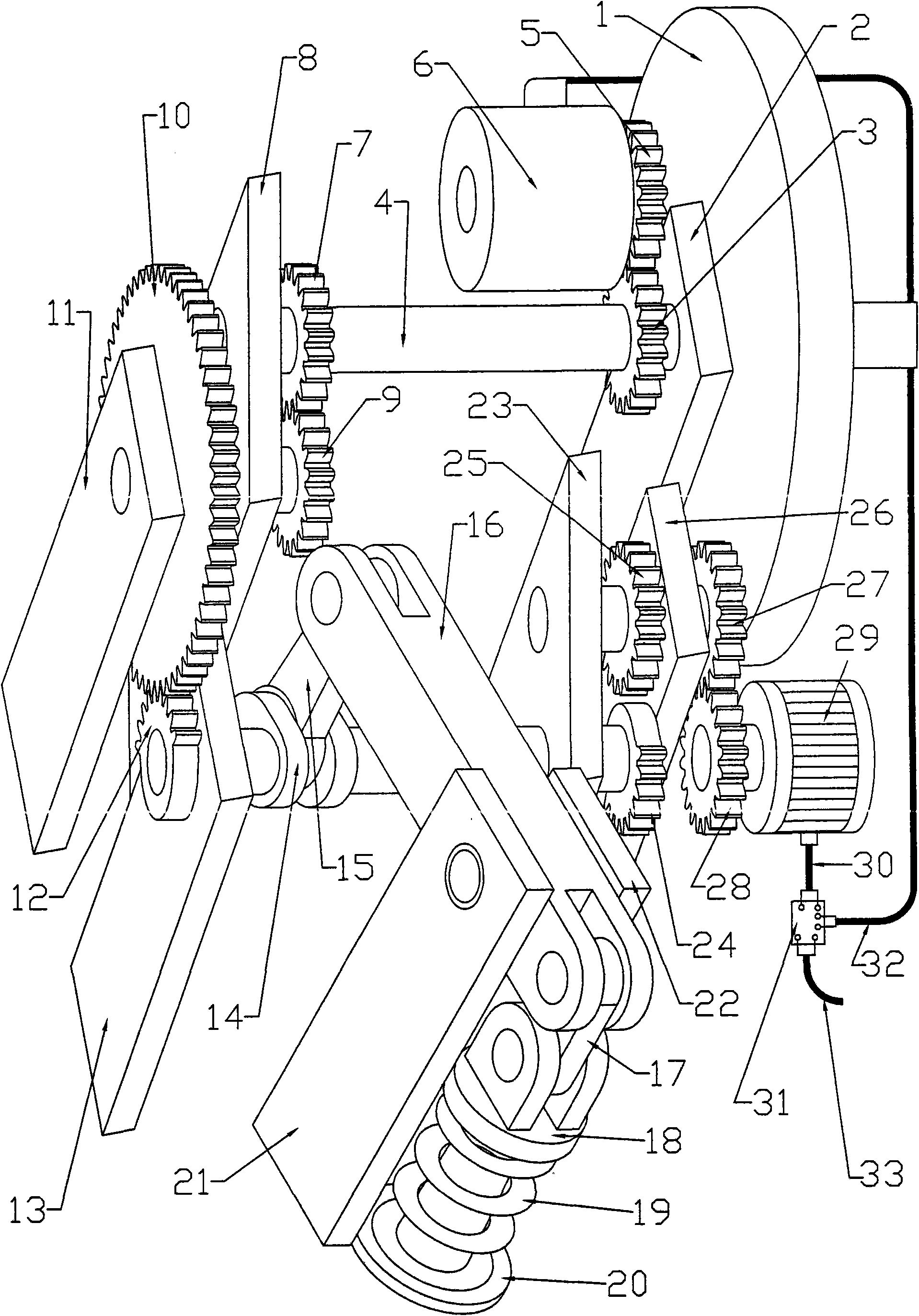

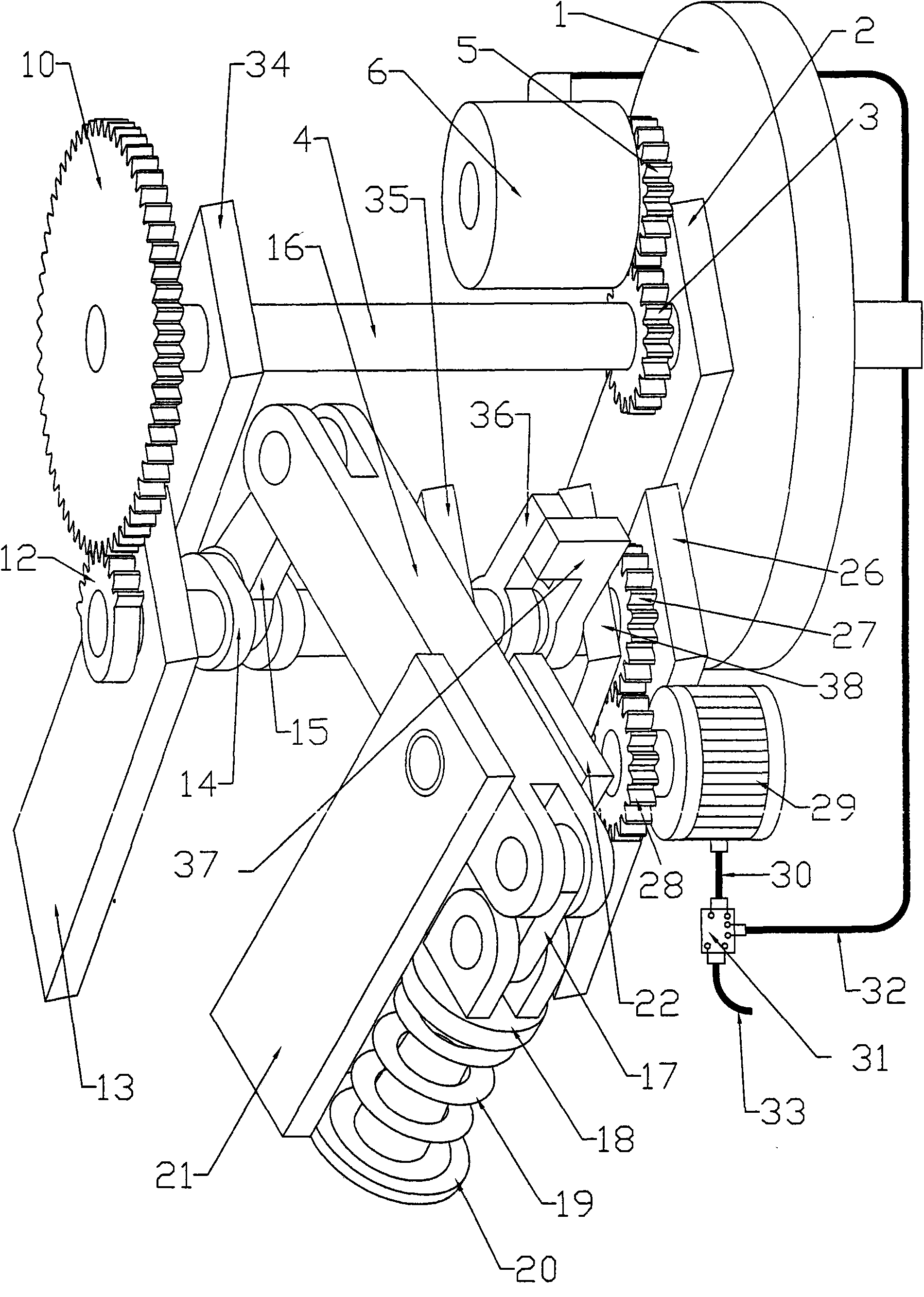

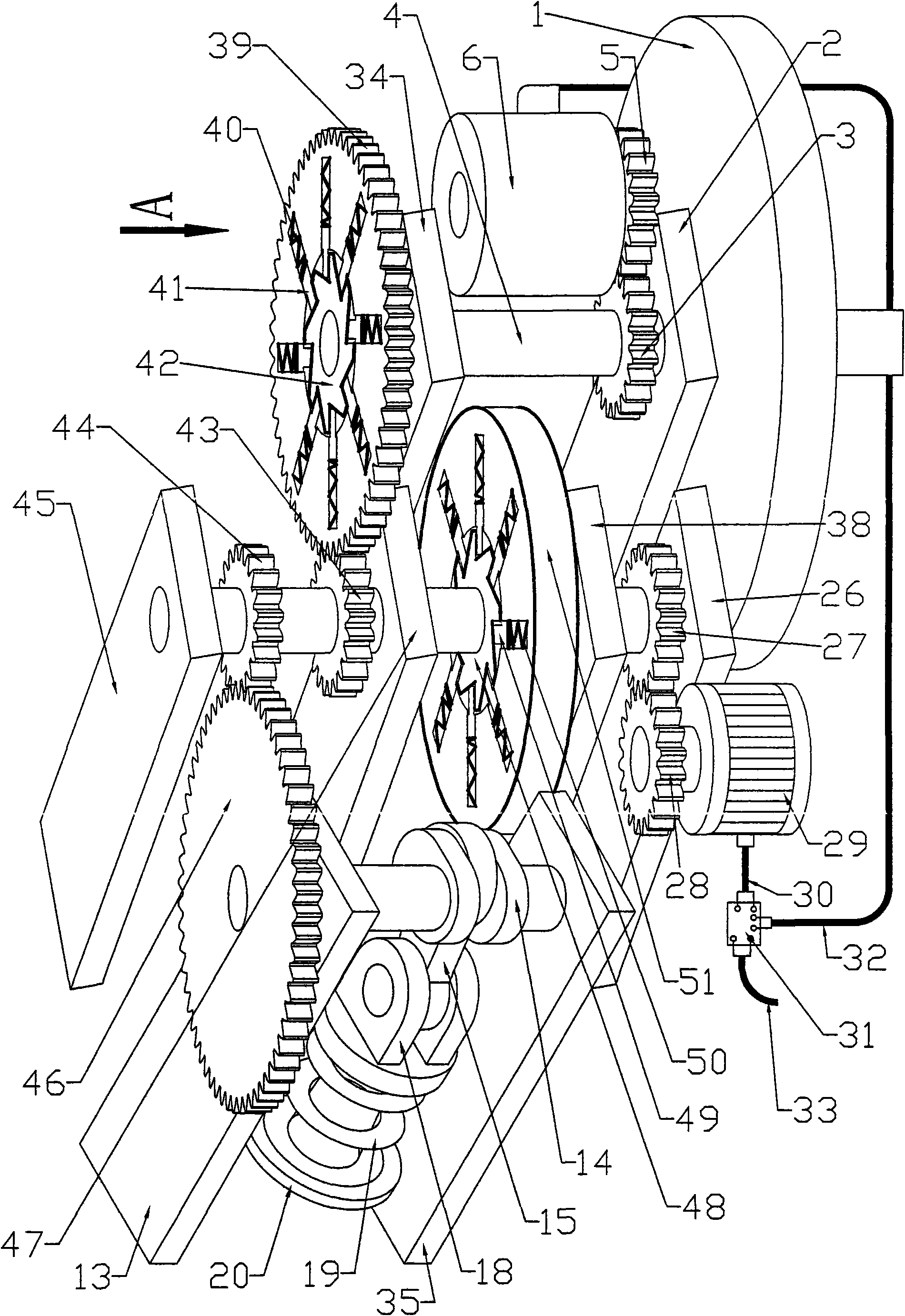

[0034] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: the present invention has nine basic principle technical schemes.

[0035] figure 1 In the shown first embodiment, each scheme of flywheel 1 is uniformly arranged on the right end of power take-off shaft 4, and the front of the left end face of flywheel 1 is power take-off bearing support I 2, and the left side of power take-off bearing support I 2 is It is the power output gear 3, the power output gear 3 is meshed with the generator gear 5, the generator gear 5 is connected to the rotating shaft of the generator 6, the generator 6 is arranged in parallel with the power output shaft 4, and the left end of the power output gear 3 The front front is the work output driven pinion 7, and the left end face front of the work output driven pinion 7 is double bearing support I 8, and the left end of the power output shaft 4 is supported by the double...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com