Printed circuit board

一种印刷电路板、集成电路的技术,应用在印刷电路、印刷电路、印刷电路制造等方向,能够解决损坏集成电路本身等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

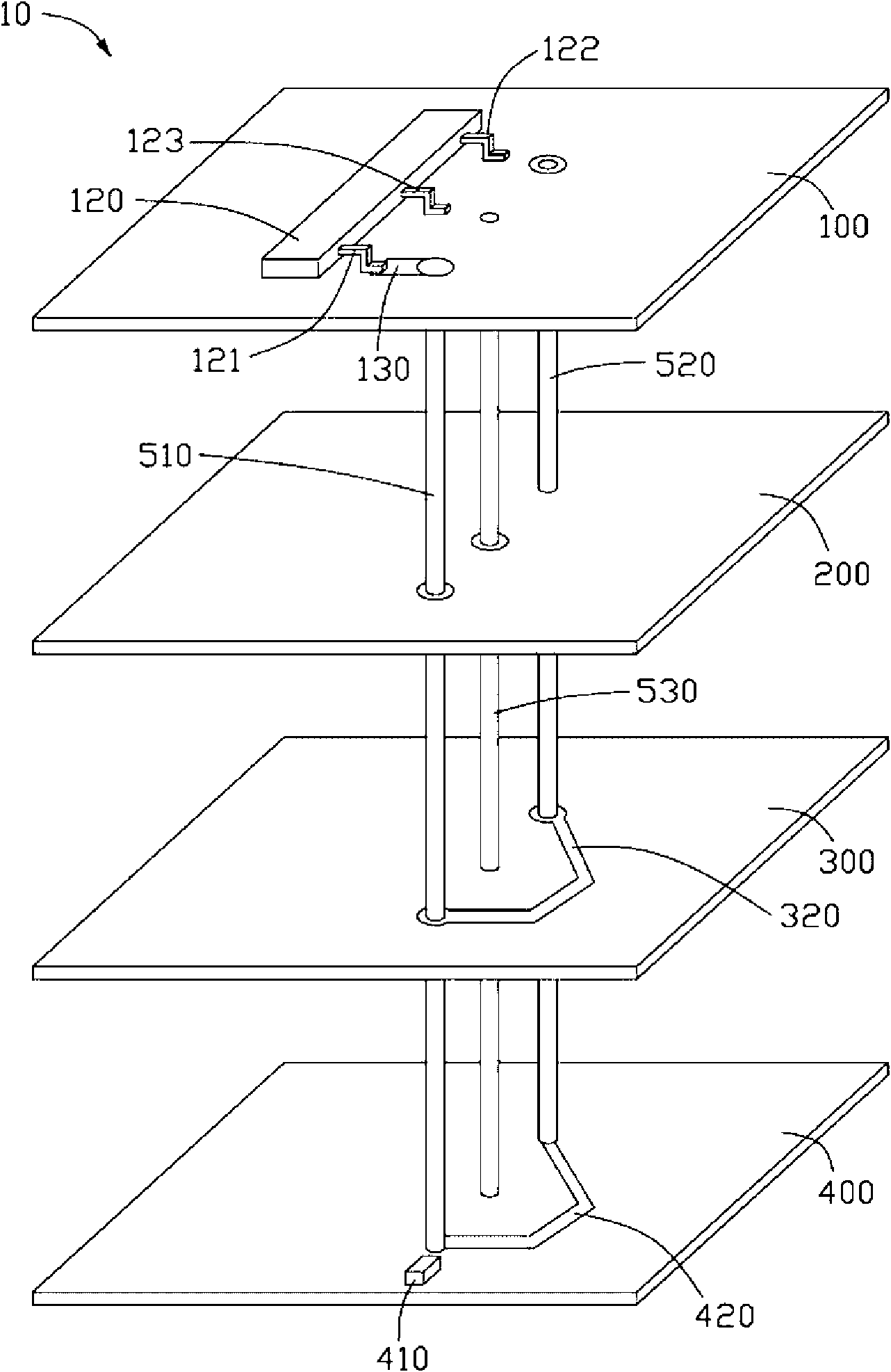

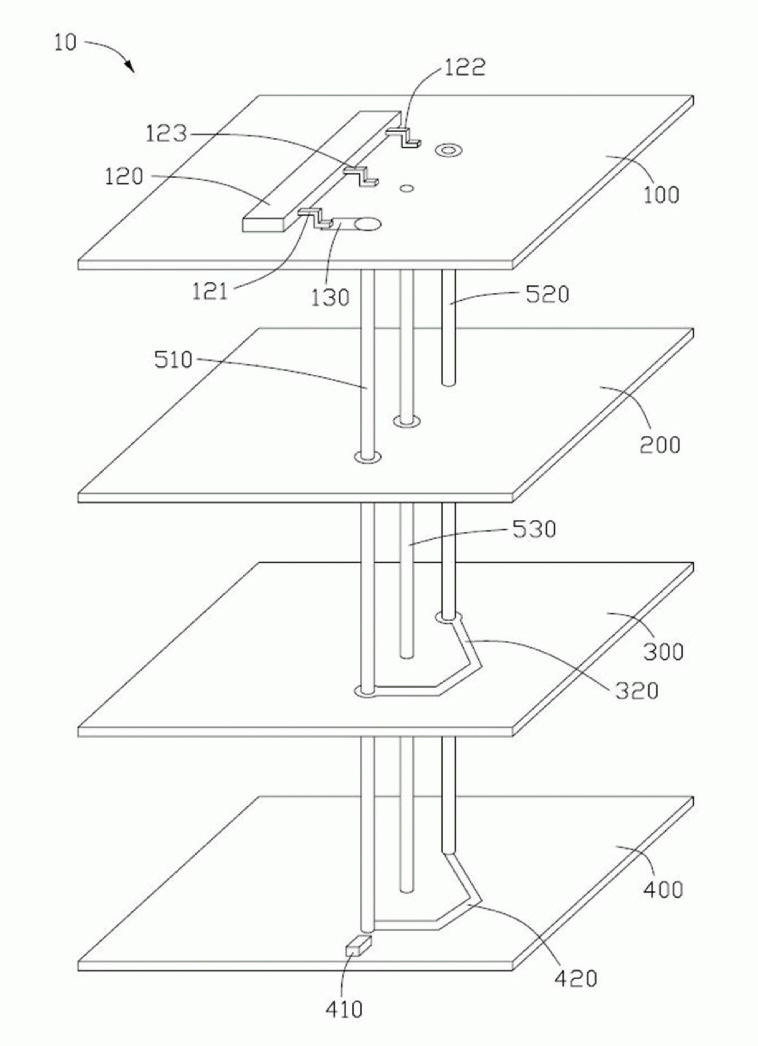

[0009] Please refer to figure 1 A preferred embodiment of the printed circuit board 10 of the present invention includes a first signal layer 100, a first reference layer (such as a power layer 200), a second reference layer (such as a ground layer 300), a second signal layer 400 . A first power supply via hole 510 , a second power supply via hole 520 and a ground via hole 530 . The power supply layer 200 is located below the first signal layer 100 , which is a power supply system of the printed circuit board 10 and is used for supplying power to components on the printed circuit board 10 . The ground layer 300 is located below the power layer 200 and above the second signal layer 400 . The first power via 510 , the second power via 520 and the ground via 530 are through holes penetrating the first signal layer 100 , the power layer 200 , the ground layer 300 and the second signal layer 400 . In this embodiment, between the first signal layer 100 and the power layer 200 , be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com