Turning tool suitable for multi-size boltings

A technology of tools and dimensions, which is applied in the manufacture of tools, wrenches, screwdrivers, etc., to reduce the quantity and cost of purchase, reduce the quantity of carrying and transportation costs, and save resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

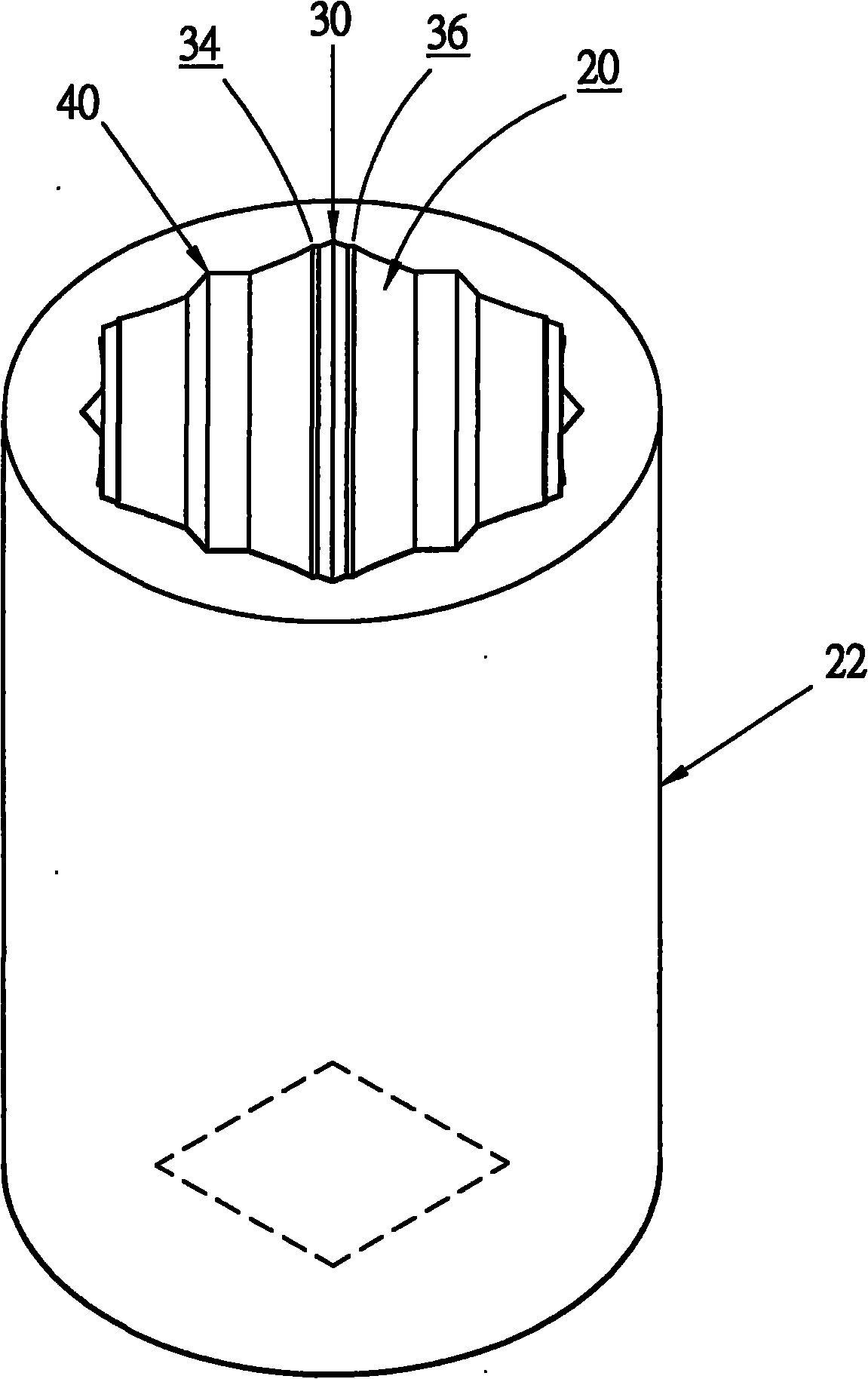

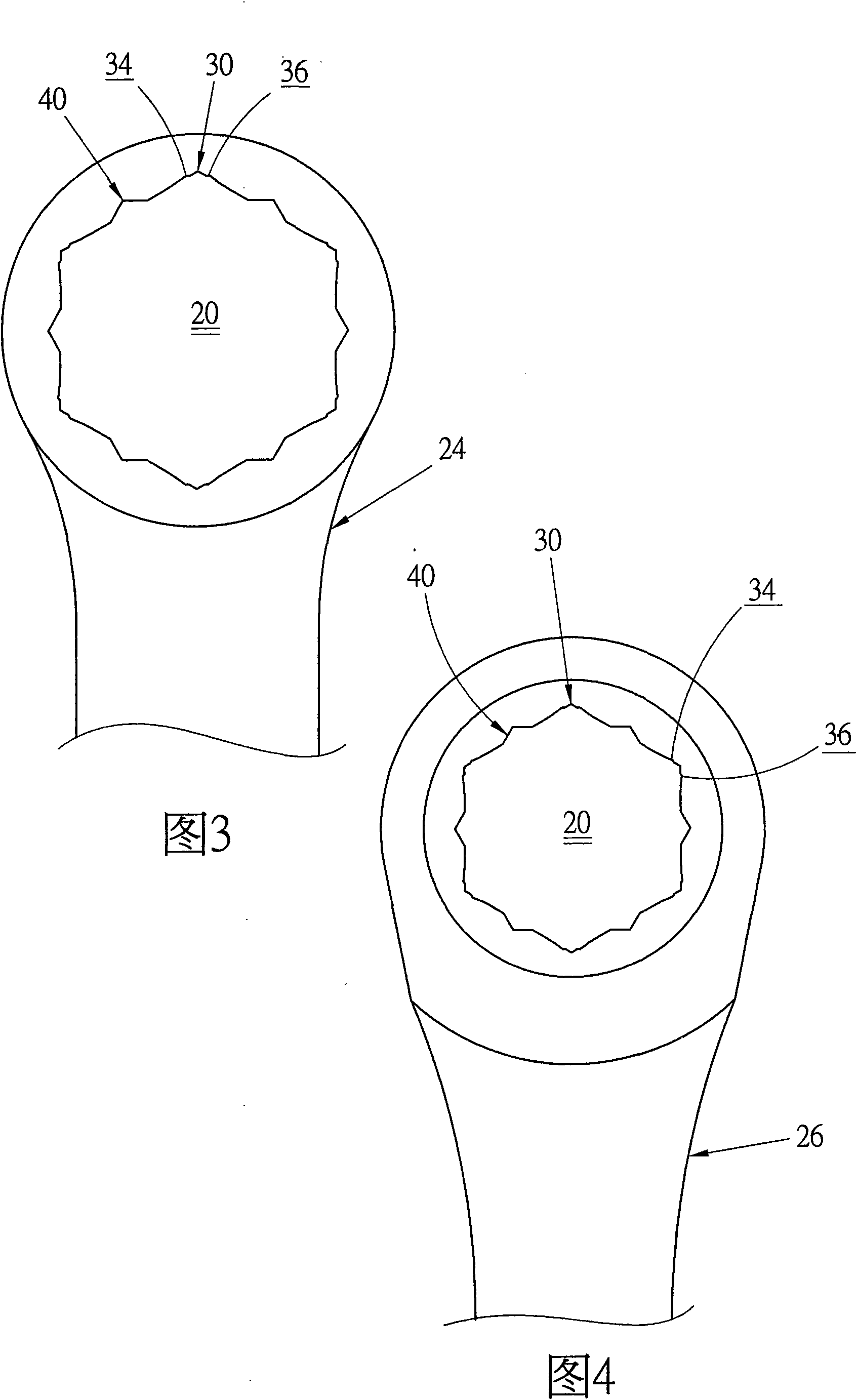

[0036] The invention provides a turning tool with a set of holes, so that the turning tool can be socketed and screwed. The turning tool that can apply the sleeve hole 20 of the present invention can be figure 2 sleeve 22 as shown; or image 3 Torx wrench 24 as shown, or as Figure 4 The ratchet wrench 26 etc. shown, in other words, the invention can be implemented in any wrenching tool capable of manipulating screws.

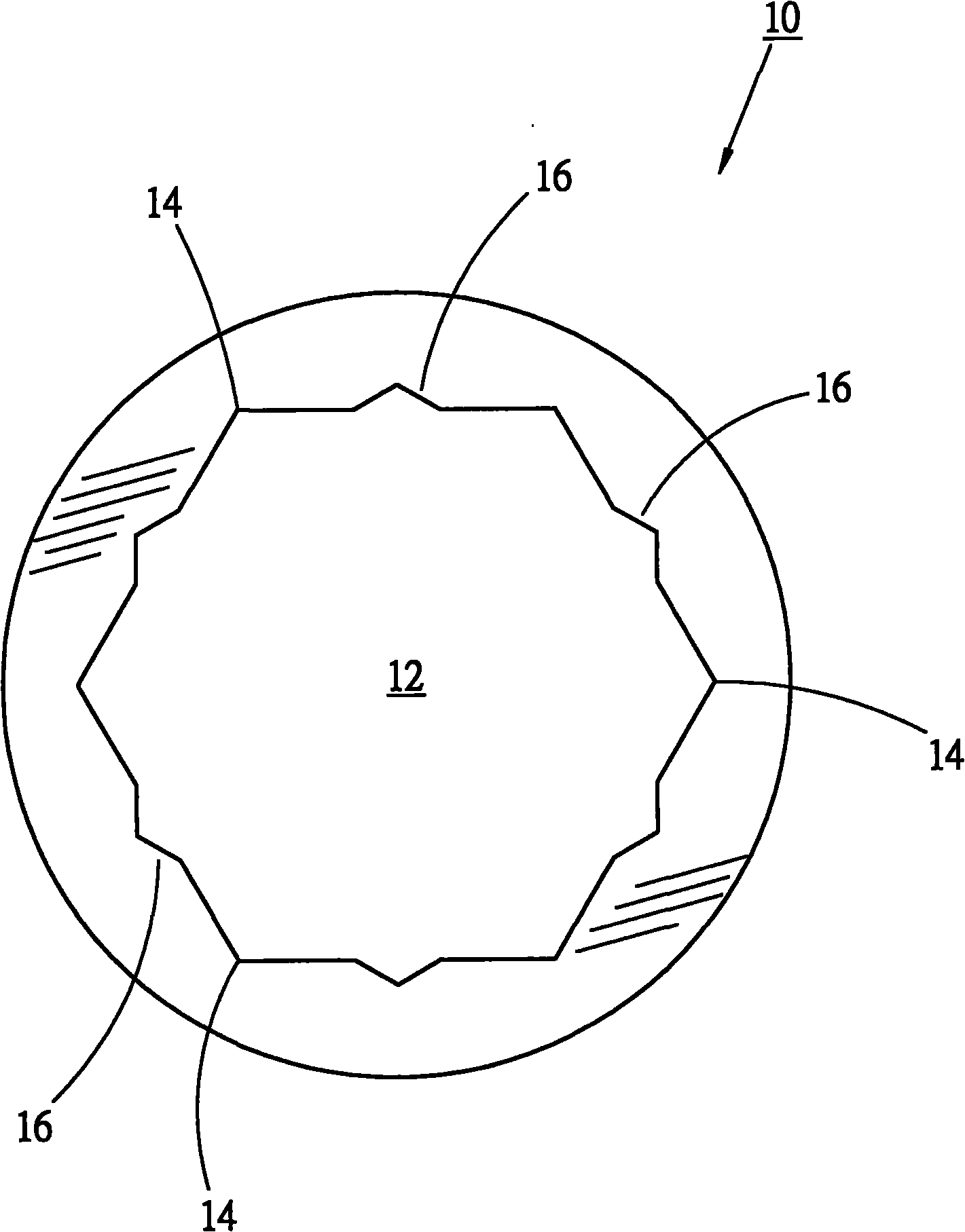

[0037] Figure 5 It is an end view of the sleeve hole 20 of a preferred embodiment of the present invention. The set of holes 20 is basically formed by two polygonal holes with the same configuration but different sizes, such as regular polygons of triangle, quadrangle or pentagon. In this embodiment, a regular hexagonal hole is taken as an example. The two hexagonal holes are arranged in a concentric manner, and have an angular difference, that is, the six inner corners 30 of the first hexagonal hole are staggered with the six inner corners 40 of the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com