Thermal print head and preparation method thereof

A technology of thermal print head and heating resistor, which is applied in printing and other directions, can solve the problem of high energy consumption of thermal print head, achieve the effect of reducing production cost, reducing energy loss, and hindering transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

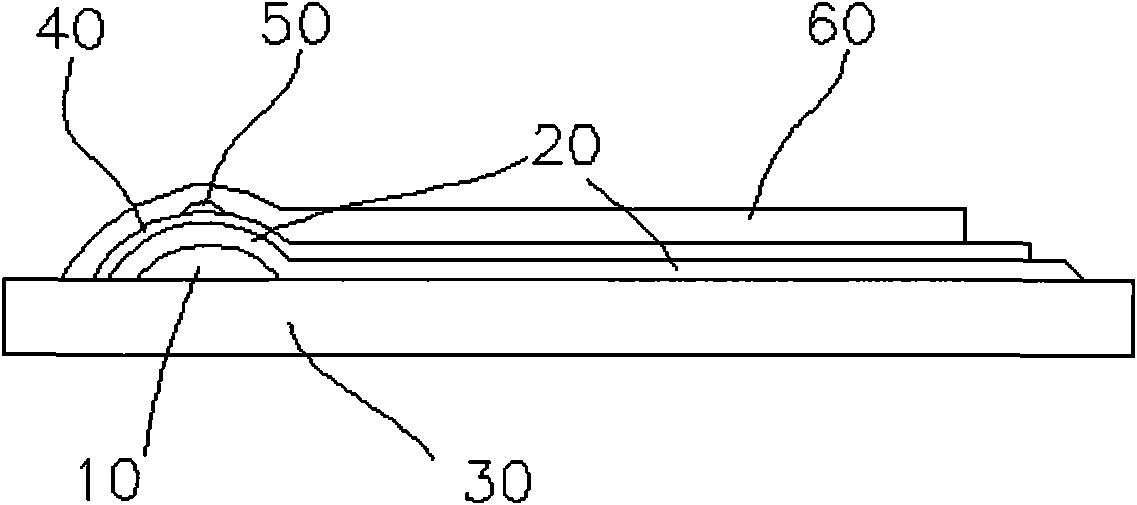

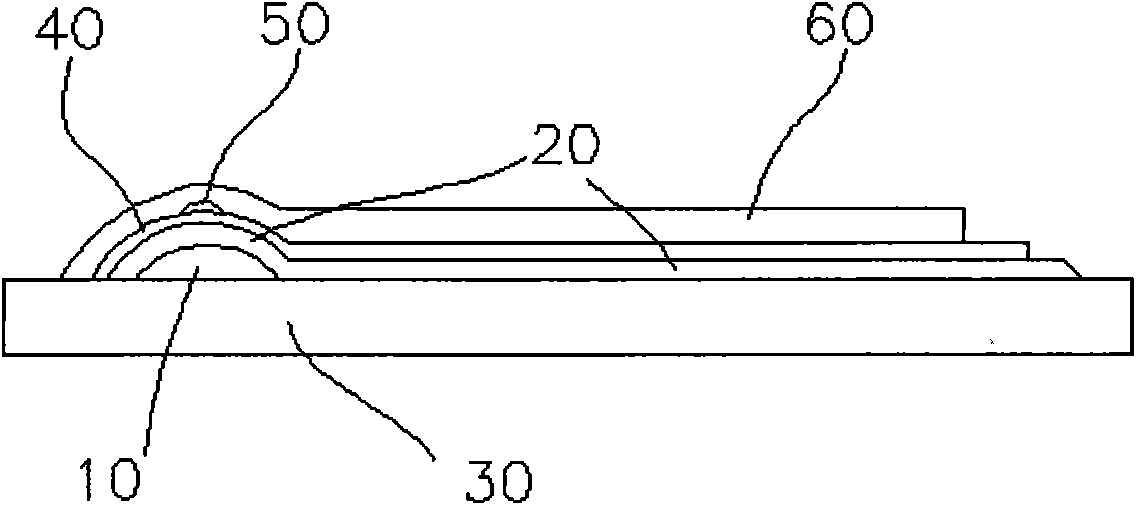

[0020] As shown in the figure: a thermal print head, including a substrate 30 made of insulating material, a partial or full underglaze layer is formed on the surface of the substrate 30, and a plurality of electrode wires 40 and a plurality of heating electrodes are arranged on the underglaze layer or the surface of the substrate 30. Resistor 50, electrode leads 40 are used to supply power to heating resistor 50, and protective layer 60 formed by thick film method or sputtering method is adopted on heating element resistor 50 and at least a part of electrode leads 40. The present invention is characterized in that substrate 30 An underglaze layer formed by an underglaze layer 10 and an overglaze layer 20 is provided, and bubbles are evenly distributed in the glaze layer to further reduce the thermal conductivity of the underglaze layer.

[0021] In the present invention, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com