Multi-composite structure component for doors and windows

A composite structure and component technology, used in building components, windows/doors, window/door frames, etc., can solve the problems of temperature insulation, sound insulation, poor airtight performance, poor damage resistance, etc., and achieve strong damage resistance, The effect of good sealing performance and good energy saving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

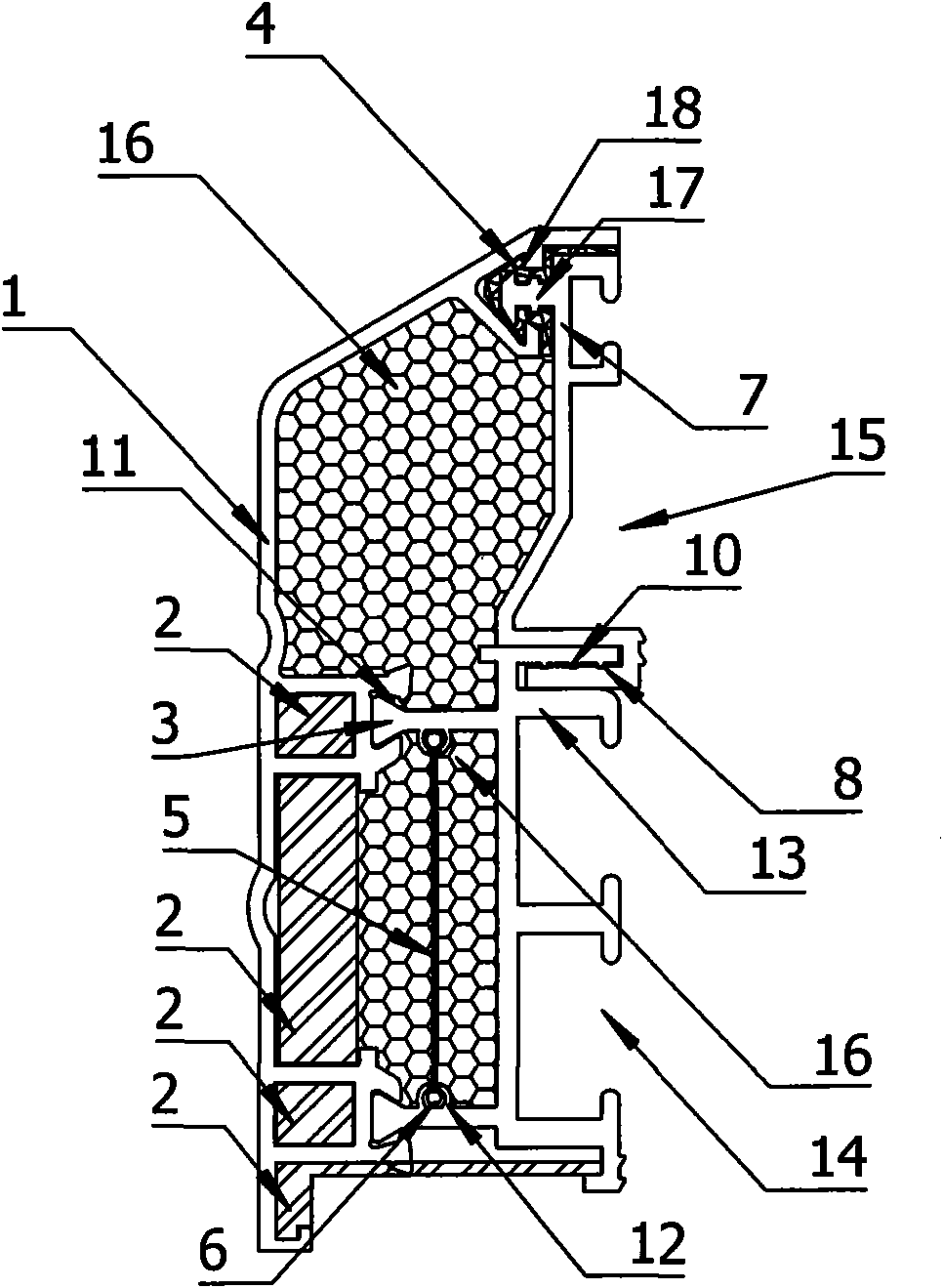

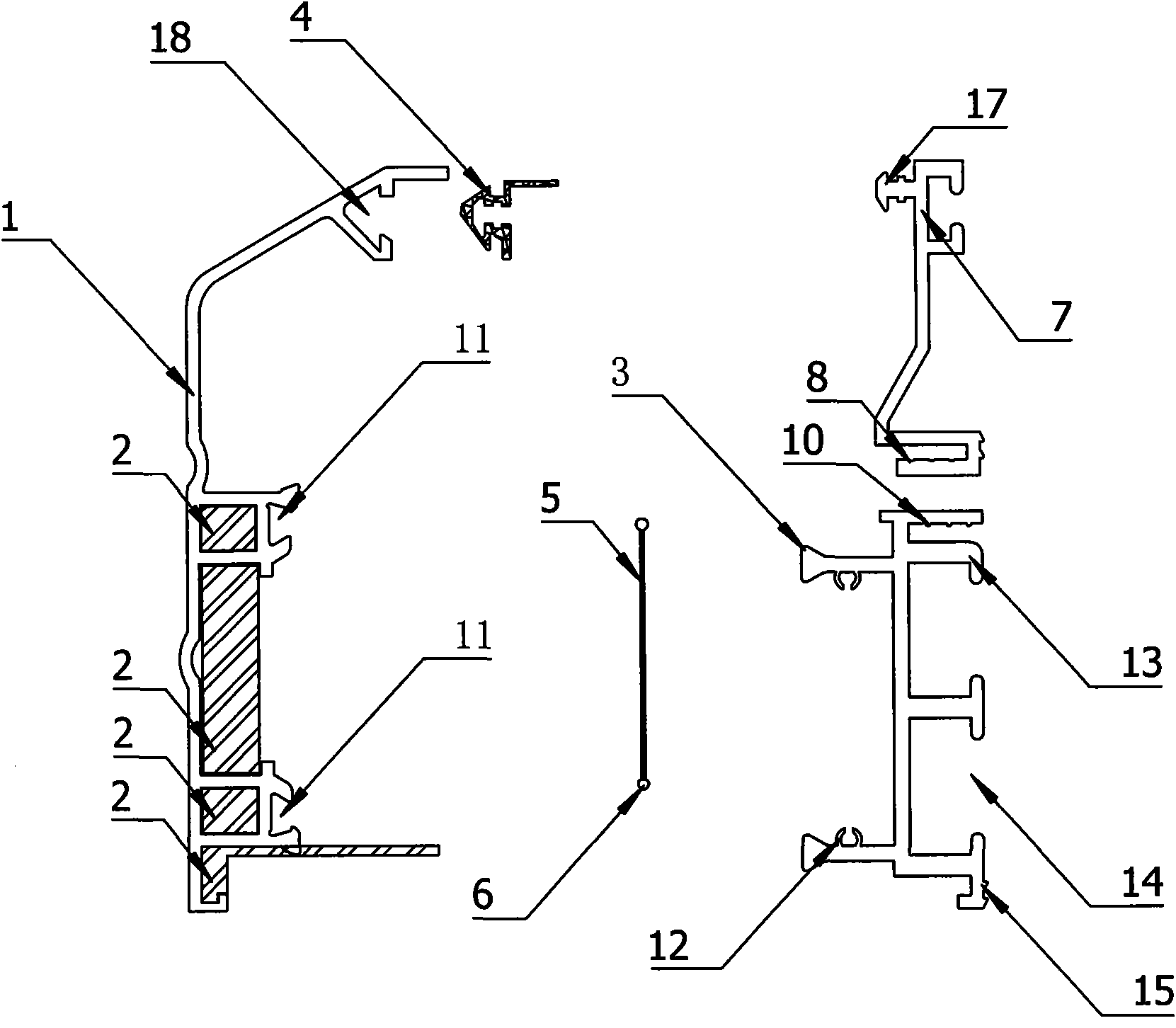

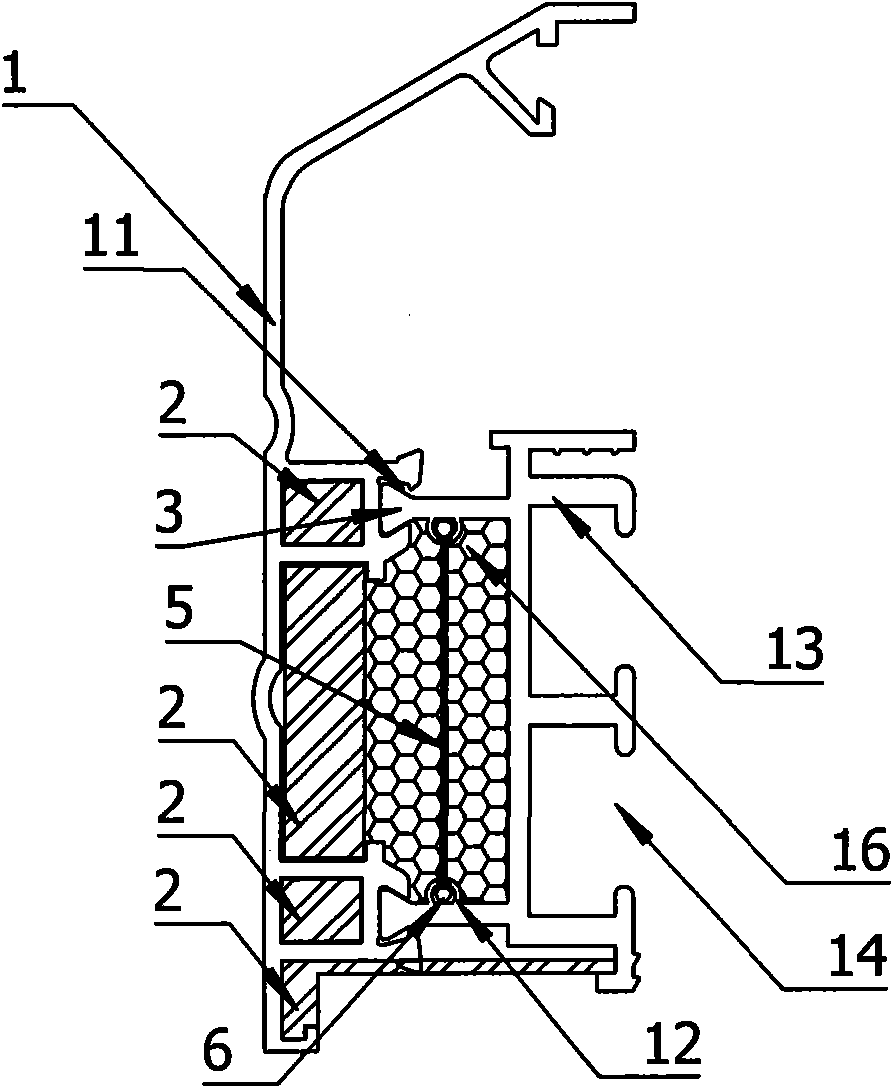

[0014] Such as figure 1 and figure 2 As shown, this embodiment includes the outer metal component 1, the inner non-metallic component 13, the inner upper non-metallic component 7, the middle heat insulation board 5 and the insulation layer 16 filled or filled in the mold cavity. A supporting piece 2 is embedded in the mold cavity of the lower half of the outer metal member 1 . The middle and lower ends of the outer metal member 1 and the upper and lower ends of the inner non-metallic member 13 are respectively connected by the connecting piece 3 protruding from the upper and lower ends of the non-metallic member 13 and the connecting piece bayonet 11 on the metal member 1 . The upper non-metallic component 7 and the non-metallic component 13 are clamped and connected by the slot 10 on the non-metallic component 13 and the matching notch 8 on the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com