Piezoresistor ceramic material and preparation method thereof

A technology of ceramic materials and varistors, which is applied in the field of varistor ceramic materials and its preparation, to achieve the effects of strong damage resistance, low price, and good nonlinear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

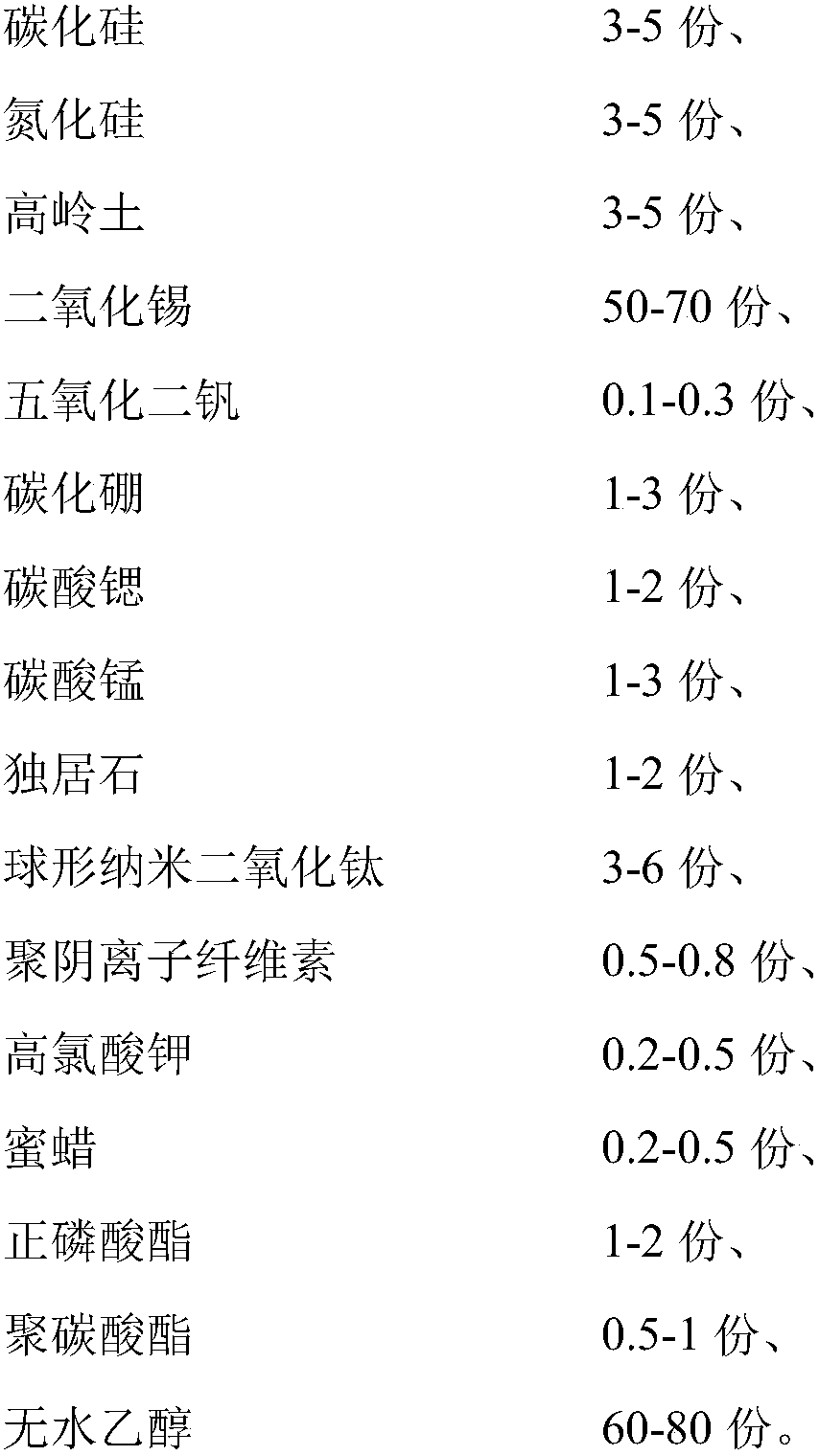

[0021] A varistor ceramic material, prepared from the following components in parts by weight: 3 parts of silicon carbide, 3 parts of silicon nitride, 3 parts of kaolin, 50 parts of tin dioxide, 0.1 part of vanadium pentoxide, and 1 part of boron carbide , 1 part of strontium carbonate, 1 part of manganese carbonate, 1 part of monazite, 3 parts of spherical nano-titanium dioxide, 0.5 part of polyanionic cellulose, 0.2 part of potassium perchlorate, 0.2 part of beeswax, 1 part of orthophosphate, 0.5 part of polycarbonate , 60 parts of absolute ethanol. The preparation method of the above-mentioned varistor ceramic material is:

[0022] (1) Mix silicon carbide, silicon nitride, kaolin, tin dioxide, vanadium pentoxide, boron carbide, strontium carbonate, manganese carbonate, monazite, spherical nano-titanium dioxide and absolute ethanol, put them into a ball mill jar Ball milling at 800r / min for 4 hours;

[0023] (2) Put it in an oven and dry it at a temperature of 100°C;

[0...

Embodiment 2

[0028] A varistor ceramic material, prepared from the following components in parts by weight: 3.5 parts of silicon carbide, 3.5 parts of silicon nitride, 3.5 parts of kaolin, 55 parts of tin dioxide, 0.15 parts of vanadium pentoxide, and 1.5 parts of boron carbide , 1.5 parts of strontium carbonate, 1.5 parts of manganese carbonate, 1.5 parts of monazite, 4 parts of spherical nano-titanium dioxide, 0.6 parts of polyanionic cellulose, 0.3 parts of potassium perchlorate, 0.3 parts of beeswax, 1.5 parts of orthophosphate, 0.6 parts of polycarbonate , 65 parts of absolute ethanol.

[0029] The preparation method of the above-mentioned varistor ceramic material is:

[0030] (1) Mix silicon carbide, silicon nitride, kaolin, tin dioxide, vanadium pentoxide, boron carbide, strontium carbonate, manganese carbonate, monazite, spherical nano-titanium dioxide and absolute ethanol, put them into a ball mill jar Ball milling at 800r / min for 4 hours;

[0031] (2) Put it in an oven and dry...

Embodiment 3

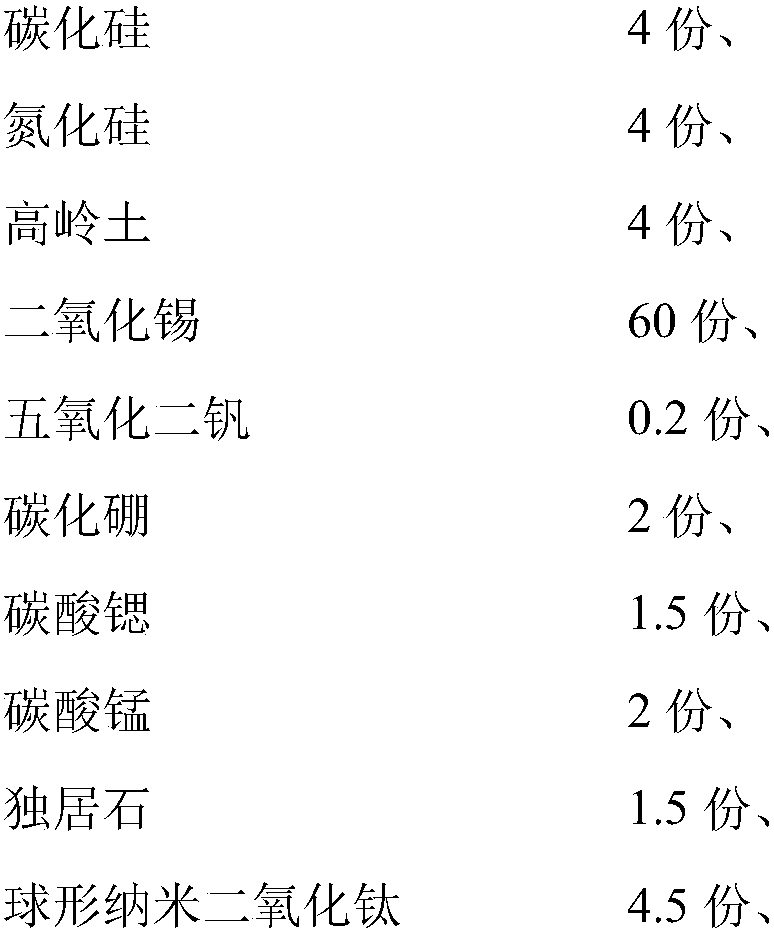

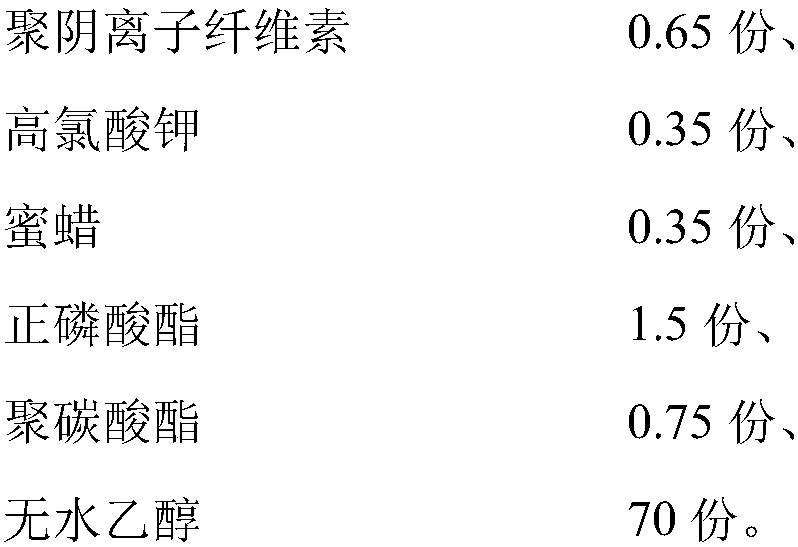

[0036] A varistor ceramic material, prepared from the following components in parts by weight: 4 parts of silicon carbide, 4 parts of silicon nitride, 4 parts of kaolin, 60 parts of tin dioxide, 0.2 parts of vanadium pentoxide, and 2 parts of boron carbide , 1.5 parts of strontium carbonate, 2 parts of manganese carbonate, 1.5 parts of monazite, 4.5 parts of spherical nano-titanium dioxide, 0.65 parts of polyanionic cellulose, 0.35 parts of potassium perchlorate, 0.35 parts of beeswax, 1.5 parts of orthophosphate, 0.75 parts of polycarbonate , 70 parts of absolute ethanol.

[0037] The preparation method of the above-mentioned varistor ceramic material is:

[0038] (1) Mix silicon carbide, silicon nitride, kaolin, tin dioxide, vanadium pentoxide, boron carbide, strontium carbonate, manganese carbonate, monazite, spherical nano-titanium dioxide and absolute ethanol, put them into a ball mill jar Ball milling at 850r / min for 4.5 hours;

[0039] (2) Put it in an oven and dry it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com