Convection type fume extractor

A body and flue technology, which is applied in the field of convection range hoods, can solve the problems that have not been put into industrial production, etc., and achieve the effects of simple structure, relatively slight friction, and smooth discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

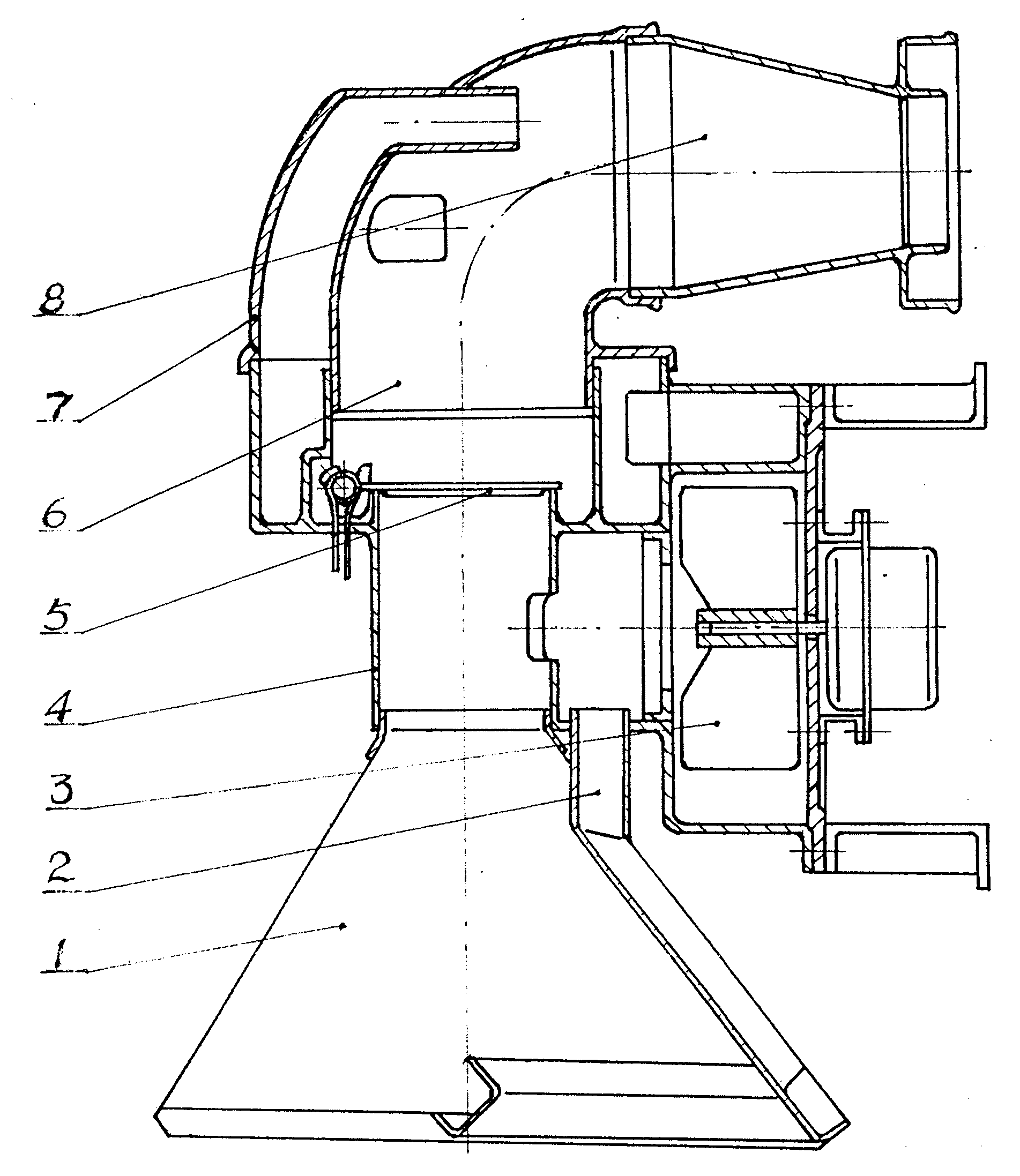

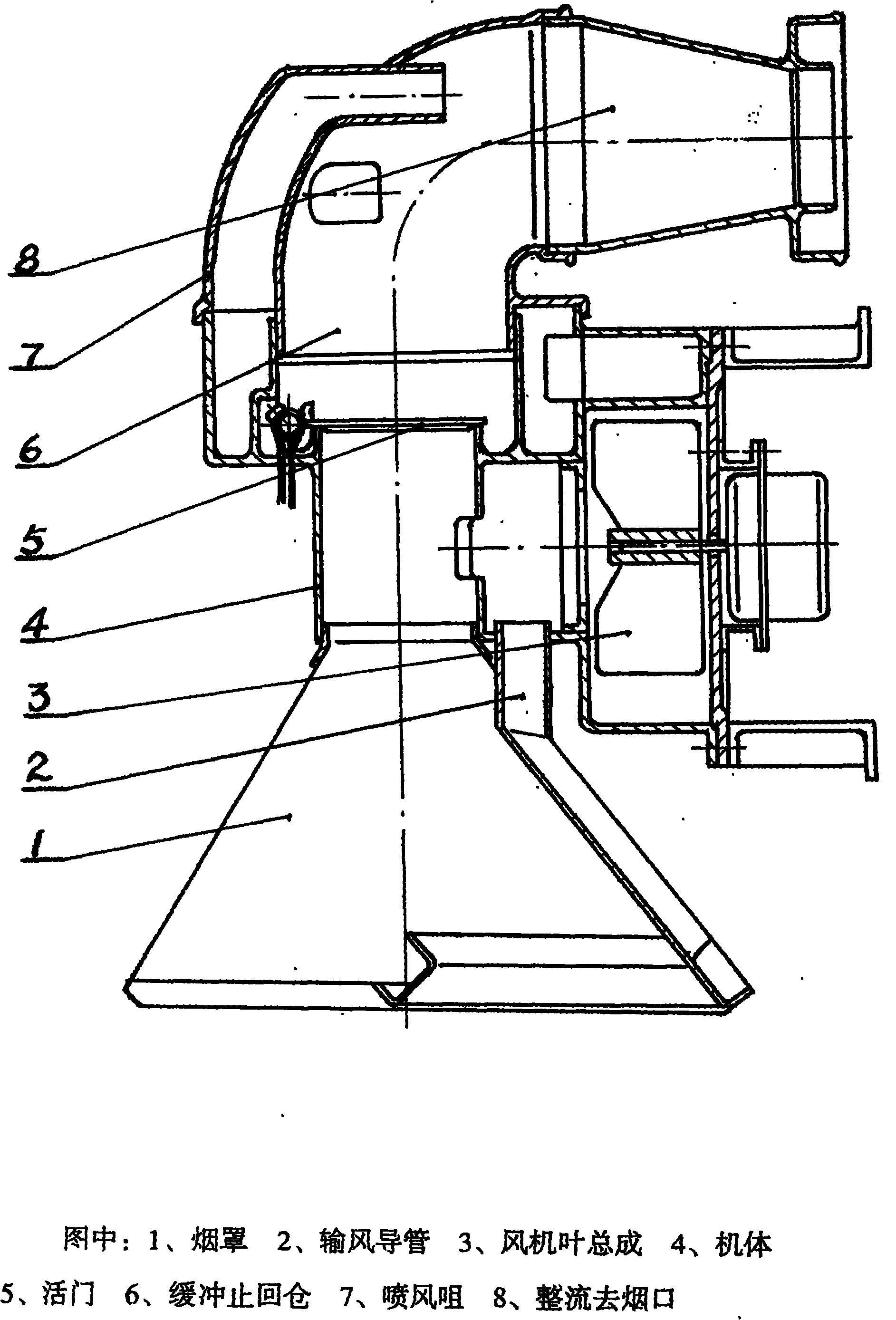

[0005] In the accompanying drawings, the body 4 has a flue hole and a centrifugal fan volute with axes perpendicularly intersecting, and the upper opening of the flue hole has a valve 5 fixed by a hinge support, which can break away from and cover the upper opening of the flue hole, and the upper opening of the flue hole There is an interlayer ring with an upward opening on the periphery of the center, and the buffer check storehouse 6 can be installed on the opening of the interlayer in any orientation to form a sealed air duct ring, and the air outlet of the air spray nozzle 7 that is integrated with the buffer check storehouse 6 It communicates with the interlayer space, and the rectifying smoke removal port 8 is installed in the upper opening of the buffer check chamber 6, the smoke hood 1 is installed in the lower opening of the flue hole, and the upper end of the air duct 2 on the smoke hood is inserted into the volute and the flue hole The connecting parts are ventilated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com