Preparation method of aluminum hydroxide powder containing lanthanum element

An aluminum hydroxide and element technology, which is applied in the field of preparation of lanthanum-containing aluminum hydroxide powder, can solve the problems of limiting catalyst reactivity and long-term stable operation, and achieves the effects of easy operation, large pore volume and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

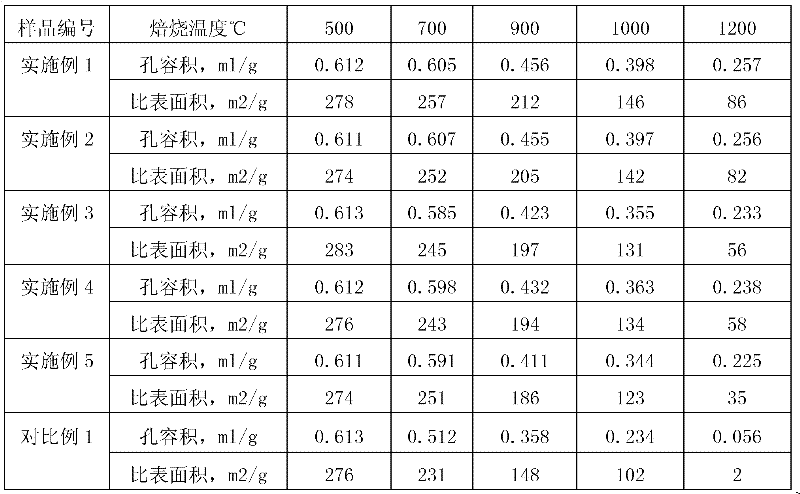

Examples

Embodiment 1

[0022] Add 10gAl to the reactor 2 o 3 / l of sodium metaaluminate solution, the temperature of the solution is controlled at 40°C. Under stirring, carbon dioxide gas with a concentration of 10% (v) was introduced. When the pH value of the reaction solution reached 9 (about 50 minutes after the start of the reaction), adding a concentration of lanthanum acetate aqueous solution was 0.1 La g / l. Continue feeding carbon dioxide gas to react, when the pH value of the reaction solution reaches 8, stop the reaction. This precipitate that is generated is based on the composition of the product: Al 2 o 3 99.8wt%, La 2 o 3 0.2 wt%. The resulting precipitate was filtered and washed with deionized water at 50° C. for 1.5 hours, and the sodium oxide content in the product was less than 0.09 wt%. Dry with a dynamic dryer at a temperature of 50°C for 1.5 hours. The dried product is pulverized to 300 orders with a jet mill, and both obtain the product of the present invention.

Embodiment 2

[0024] Add 45g Al to the reactor 2 o 3 / l of sodium metaaluminate solution, the temperature of the solution is controlled at 5°C. Under stirring, carbon dioxide gas with a concentration of 40% (v) was introduced. When about 30 minutes after the start of the reaction, an aqueous solution of lanthanum nitrate having a concentration of 8 La g / l was added. Continue feeding carbon dioxide gas to react, when the pH value of the reaction solution reaches 12, stop the reaction. This precipitate that is generated is based on the composition of the product: Al 2 o 3 94wt%, La 2 o 3 6.0 wt%. The resulting precipitate was filtered and washed with deionized water at 80° C. for 2.5 hours, and the sodium oxide content in the product was less than 0.08 wt%. Dry with a dynamic dryer at a temperature of 150°C for 0.5 hours. The product after drying is pulverized to 80 orders with jet mill, both obtains the product described in the present invention

Embodiment 3

[0026] Add 35gAl to the reactor 2 o 3 / l of sodium metaaluminate solution, the temperature of the solution is controlled at 10°C. Under stirring, carbon dioxide gas with a concentration of 30% (v) was introduced. When about 20 minutes after the start of the reaction, an aqueous solution of lanthanum acetate having a concentration of 6 La g / l was added. Continue feeding carbon dioxide gas to react, when the pH value of the reaction solution reaches 10, stop the reaction. This precipitate that is generated is based on the composition of the product: Al 2 o 3 96wt%, La 2 o 3 4wt%. The resulting precipitate was filtered and washed with deionized water at 70° C. for 1.0 hour, and the sodium oxide content in the product was less than 0.07 wt%. Dry with a dynamic dryer at a temperature of 130°C for 0.6 hours. The product after drying is pulverized to 100 orders with jet mill, both obtains the product described in the present invention

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com