Anti-back-suction electronic pipettor

An anti-suckback and pipette technology, which is applied in the field of pipettes, can solve the problems of affecting the progress of experiments, cross-contamination of samples, shortening the service life of pipettes, etc., and achieve the effect of preventing cross-contamination of solvents and prevention of suckback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

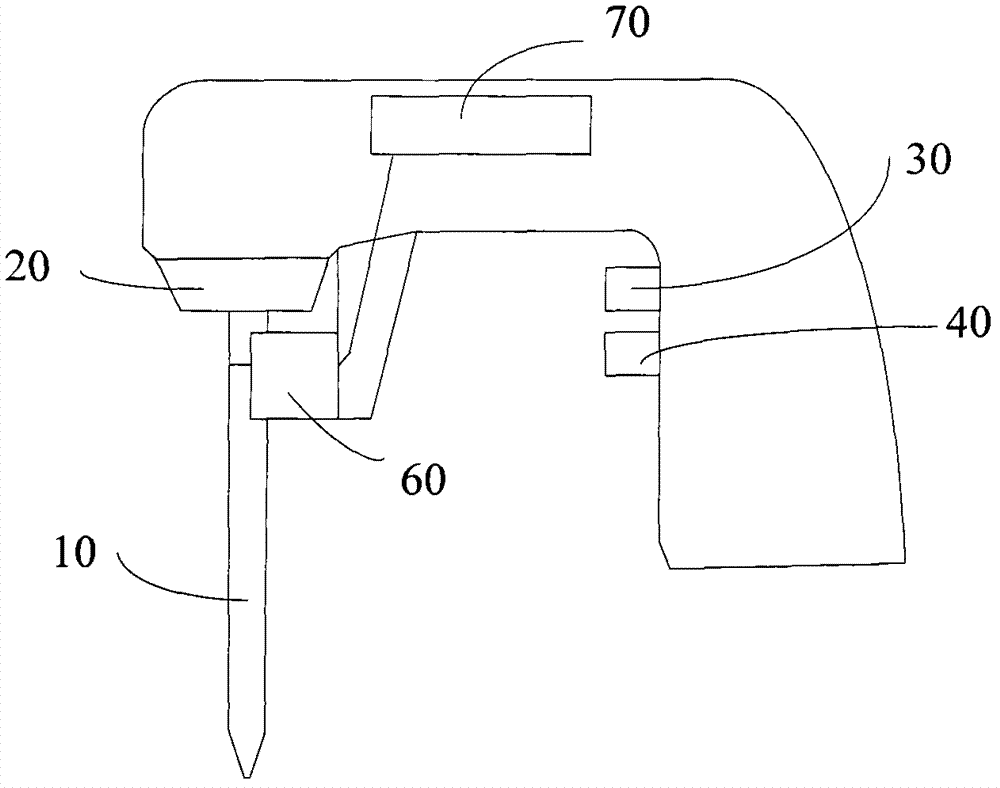

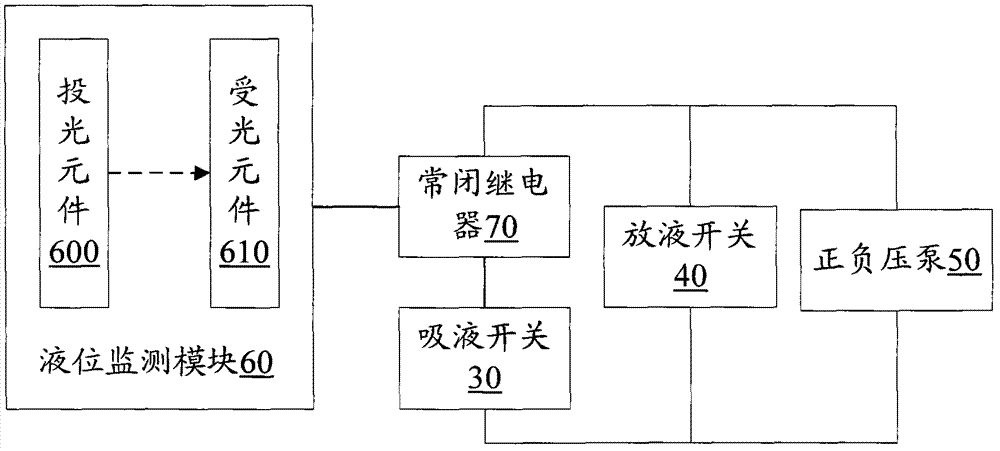

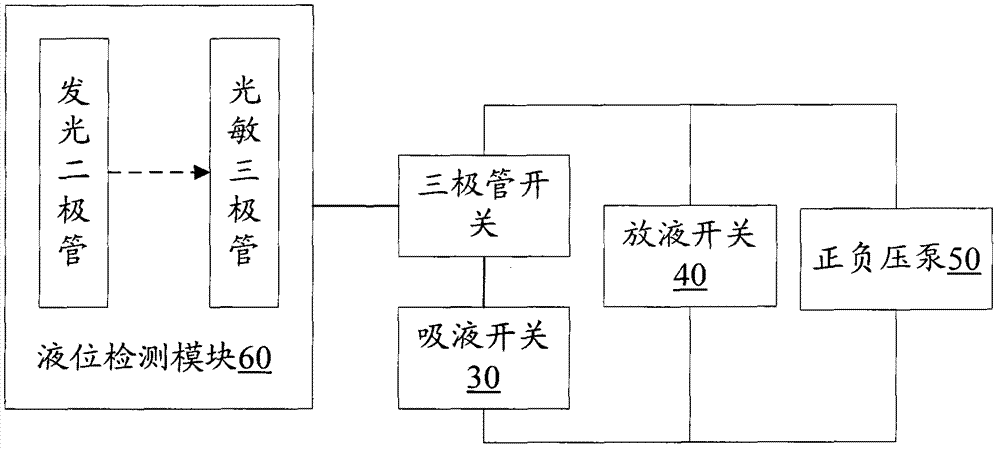

[0017] Such as figure 1 and figure 2 As shown, in one embodiment, a kind of anti-suck back electronic pipette, comprises pipette 10, the pipette joint 20 that installs pipette 10, the suction switch 30 that is connected in parallel, the liquid discharge switch 40 and positive Negative pressure pump 50, liquid level monitoring module 60. Wherein, the liquid suction switch 30 is connected with the liquid level monitoring module 60 . The liquid level monitoring module 60 is used to monitor a predetermined monitoring plane on the pipette 10 and generate a corresponding monitoring signal, and control the state of the suction switch 30 according to the corresponding monitoring signal. The liquid suction switch 30 connected in parallel and the positive and negative pressure pumps 50 constitute a liquid suction control circuit, and the liquid discharge switch 40 and the positive and negative pressure pumps 50 constitute a liquid discharge control circuit. The predetermined monitor...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap