Method for machining anti-side-rolling torsion bar shaft of railway vehicle and floating grinding device thereof

An anti-roll torsion bar, rail vehicle technology, applied in metal processing equipment, grinding/polishing equipment, machine tools designed for grinding workpiece rotating surfaces, etc. Problems such as poor fatigue performance of rod shafts can reduce the consumption of raw materials, save raw materials, and improve the mechanical strength of products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings.

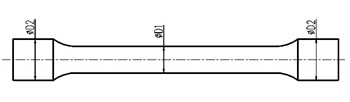

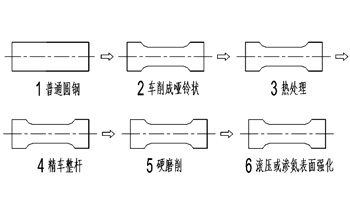

[0050] Such as Figure 4 As shown, the present invention relates to a method for manufacturing anti-rolling torsion bar shafts for rail vehicles, directly using polished raw materials, and manufacturing torsion bar shafts according to the following procedures and process conditions:

[0051] 1. Upsetting the end to form a dumbbell-shaped structure: Use polished raw materials to cut the material according to the length required for the anti-rolling torsion bar shaft, and then place the polished raw materials horizontally on the horizontal upsetting forming machine. The mold on the upsetting forming machine clamps the polished raw material, and then the two ends of the material are upset by the horizontal pier hammer on the horizontal upsetting forming machine to make it into a dumbbell-shaped structure.

[0052] Since the product is a slender shaft, the blanking length...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com