Method and equipment for pressing and forming building blocks

A technology of pressing and forming blocks, which is applied in the direction of forming indenters, ceramic molding machines, manufacturing tools, etc., and can solve problems such as time-consuming, laborious, costly, and complicated processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

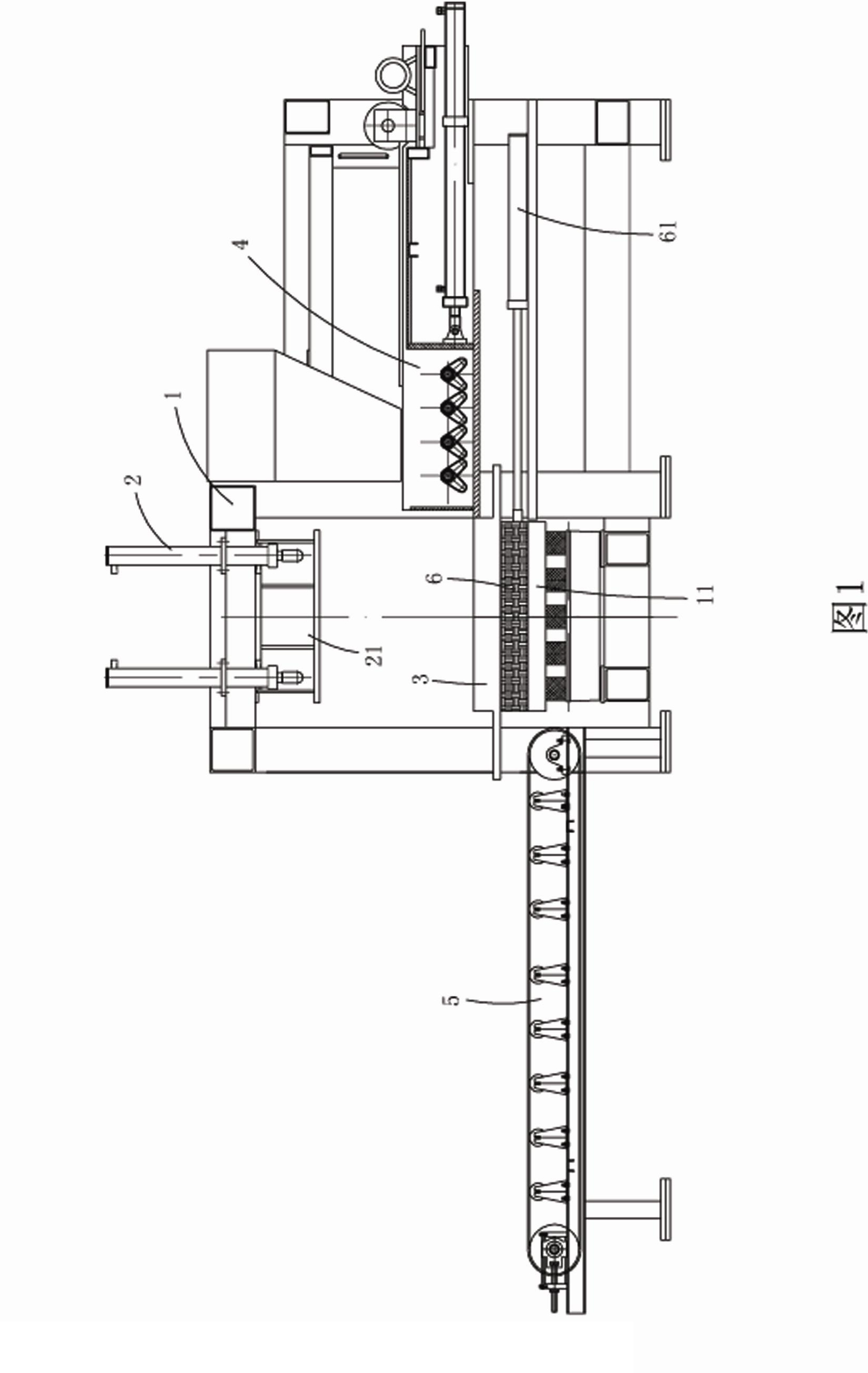

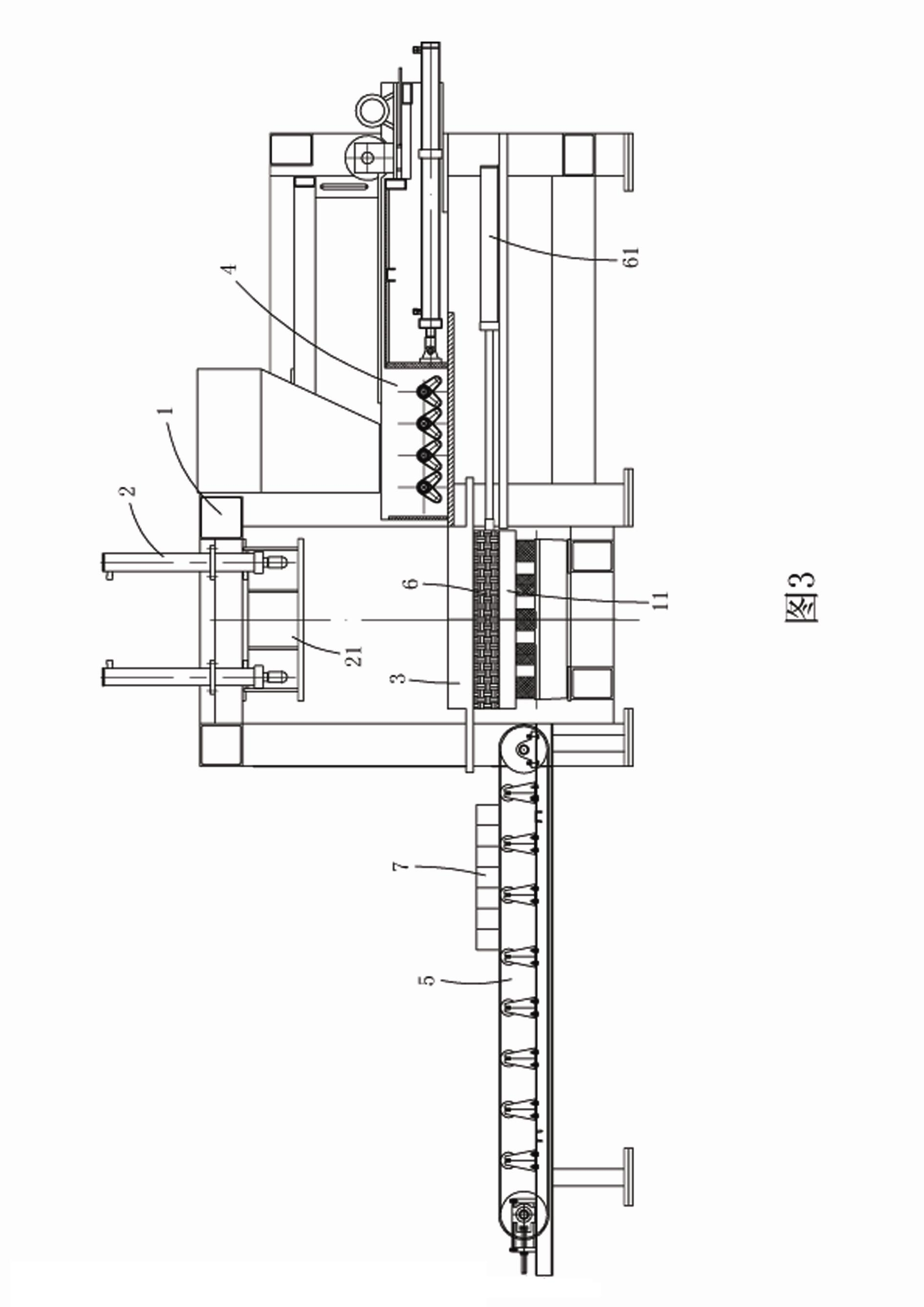

[0026] refer to Figure 1 to Figure 3 . A block press molding machine of the present invention comprises a frame 1, an upper pressure head oil cylinder 2 fixed on the top of the frame 1, an upper pressure head 21, a forming mold box 3, a material distribution vehicle 4, a brick connecting machine 5, and a supporting plate 6 and a reciprocating plate feeding oil cylinder 61, a horizontal workbench 11 is provided at the bottom of the frame 1, and an upper pressing head 21 is arranged above the forming mold box 3 and connected with the piston of the upper pressing head oil cylinder 2; Relatively arranged on both sides of the rack 1. The forming mold box 3 is fixedly installed on the frame 1 column between the horizontal workbench 11 and the upper pressing head 21 by a locking device, and there is a space for forming bricks to pass between the fixed forming mold box 3 and the horizontal working platform 11. And the distance is equivalent to the height of the forming mold box 3 ....

Embodiment 2

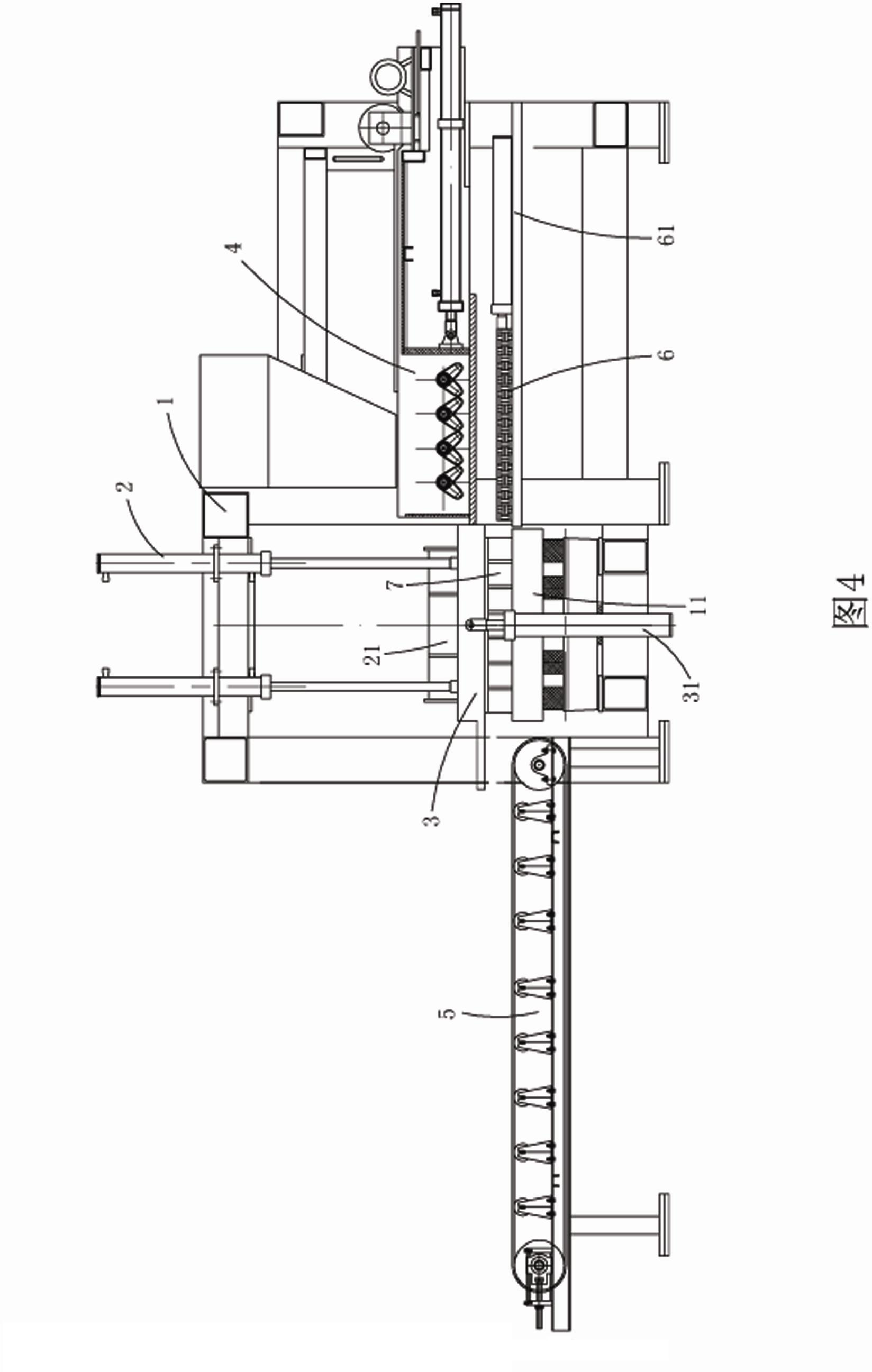

[0035] refer to Figure 4. This implementation example is different from Embodiment 1 in that: the molding mold box 3 is slidingly fitted on the frame 1 column above the horizontal workbench, and the lifting cylinder 31 connected with the molding mold box 3 is installed on the frame 1, and the lifting cylinder 31 It can drive the forming mold box 3 to move up and down along the column, so as to complete the demoulding of cooperating with the upper pressing head 21 to press and form the adobe. Supporting plate 6 is a conventional supporting plate, and the spacing between the forming mold box 3 and the horizontal working platform 11 in the pressing station is less than the height of the forming brick adobe 7 .

[0036] refer to Figure 4 and refer to Figure 1 to Figure 3 . The working method of the block press forming machine provided by the present embodiment 2 comprises the following steps:

[0037] (1) To set the initial state of each component, first adjust the forming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com