Polycrystalline working plate for disassembled or assembled wire squarer

A square cutting machine and working board technology, which is applied in the direction of fine working devices, manufacturing tools, stone processing equipment, etc., can solve the problems that affect the qualified rate of processed workpieces, increase the burden of hoisting tools, and increase the difficulty of hoisting, so as to improve the quality of the machine. The effect of stability, reducing the difficulty of hoisting and reducing the difficulty of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific drawings and embodiments.

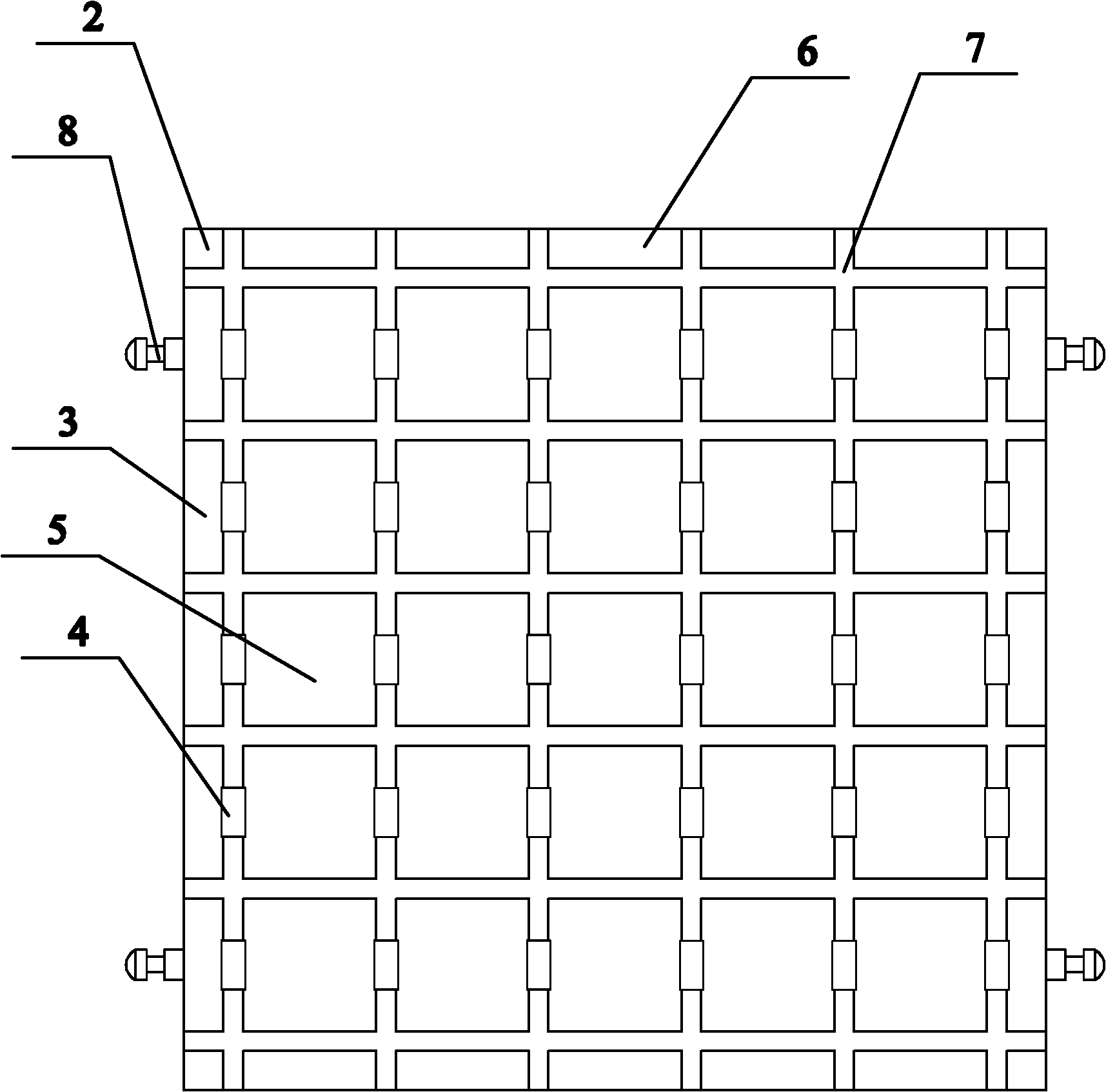

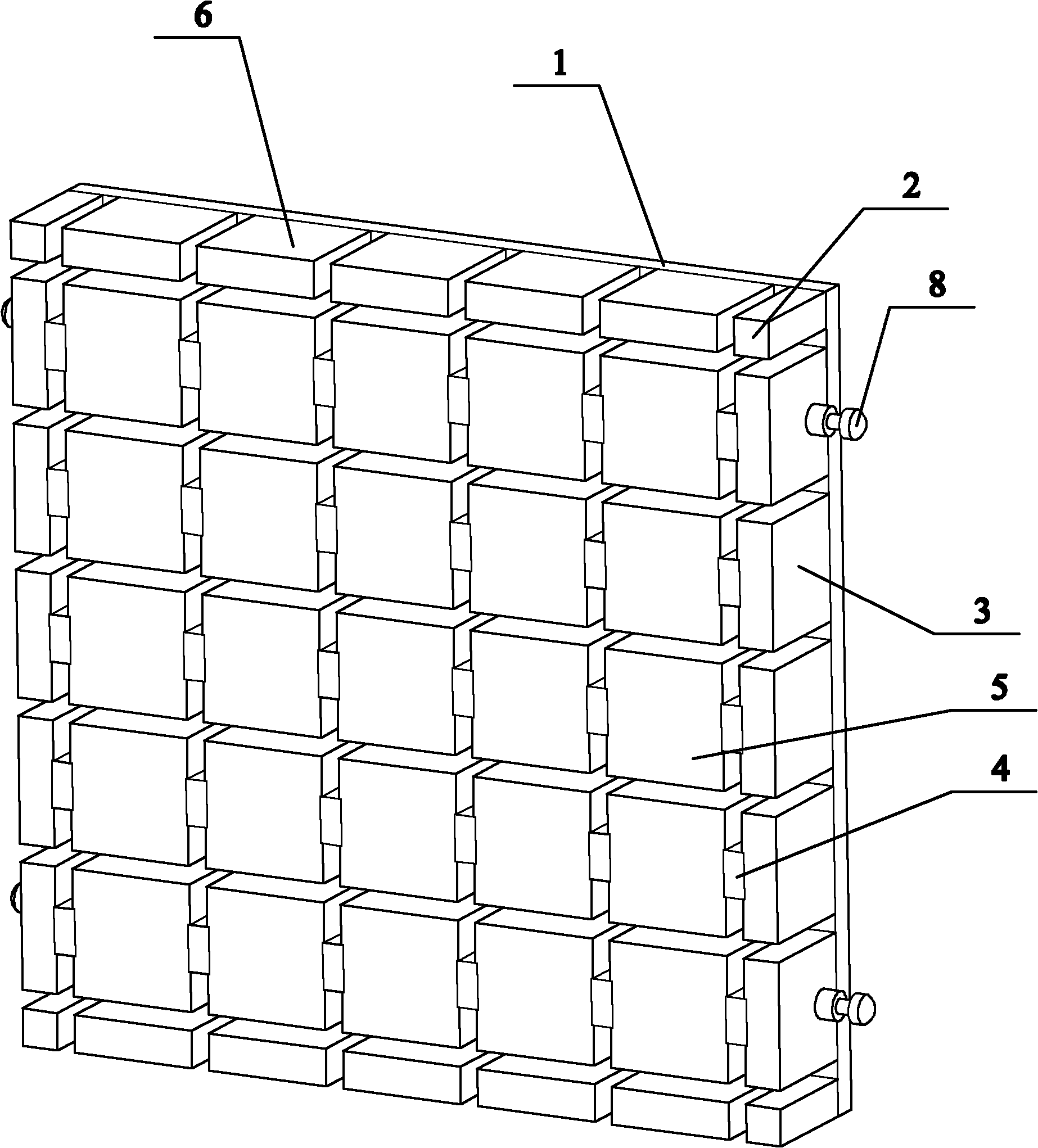

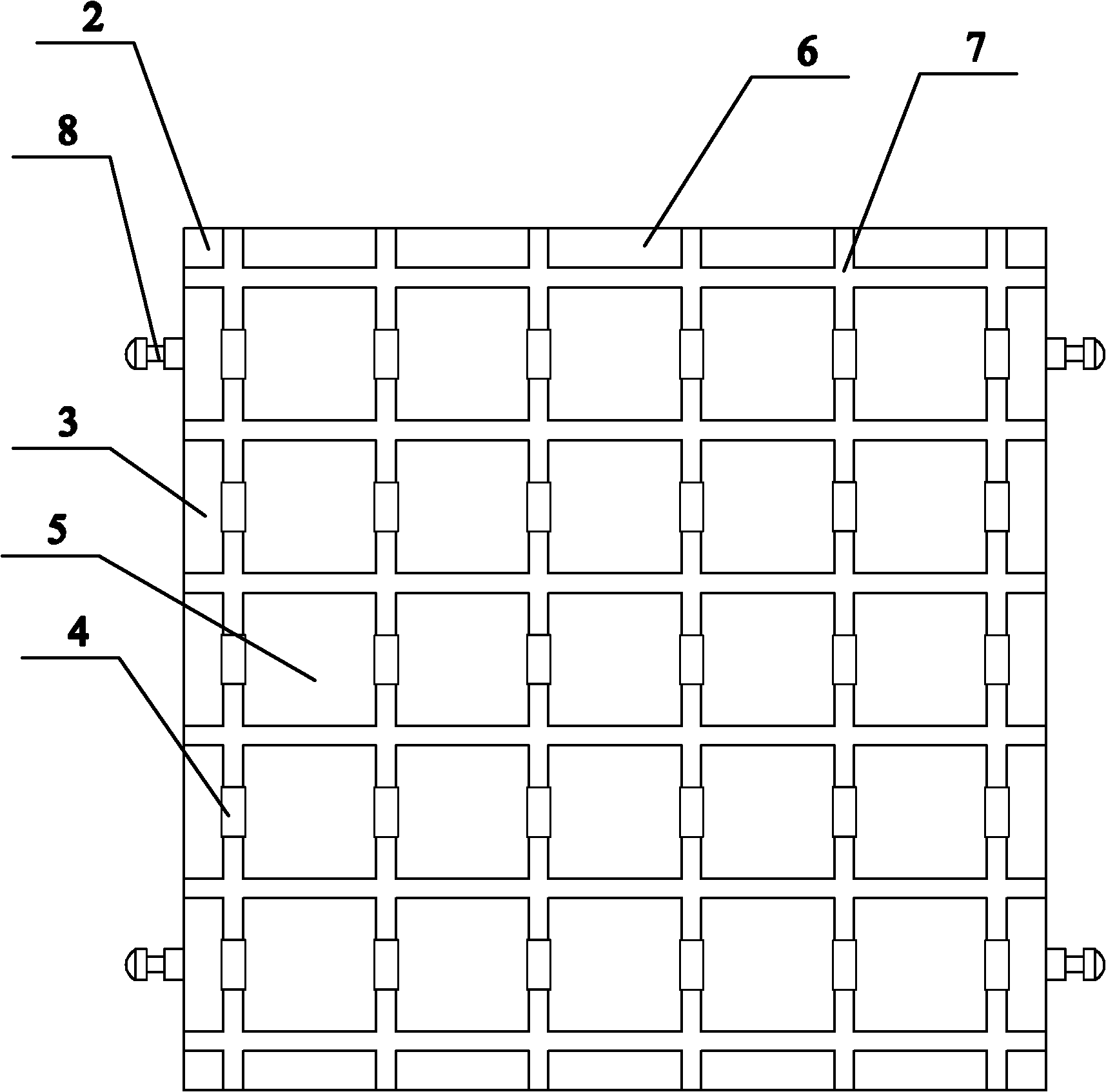

[0013] Such as figure 1 Shown: The polycrystalline working plate of the detachable and combined wire square cutting machine, including the base plate 1 and the pads fixed on the base plate 1, the pads include the first pad 6, the second pad 2, the third pad block 3, the fourth pad 4 and the fifth pad 5; the first pads 6 are evenly spaced and horizontally arranged on the outer ring of the bottom plate 1; the third pads 3 are evenly spaced and longitudinally arranged on the outer ring of the bottom plate 1 The fifth pads 5 are evenly spaced in the middle of the bottom plate 1; the second pads 2 are distributed at the four corners of the bottom plate 1. The pads are evenly spaced and fixed on the bottom plate 1 , and the intervals between adjacent pads form criss-cross bottom plate grooves 7 .

[0014] The height of each spacer is 115mm, 125mm or 135mm, so that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com