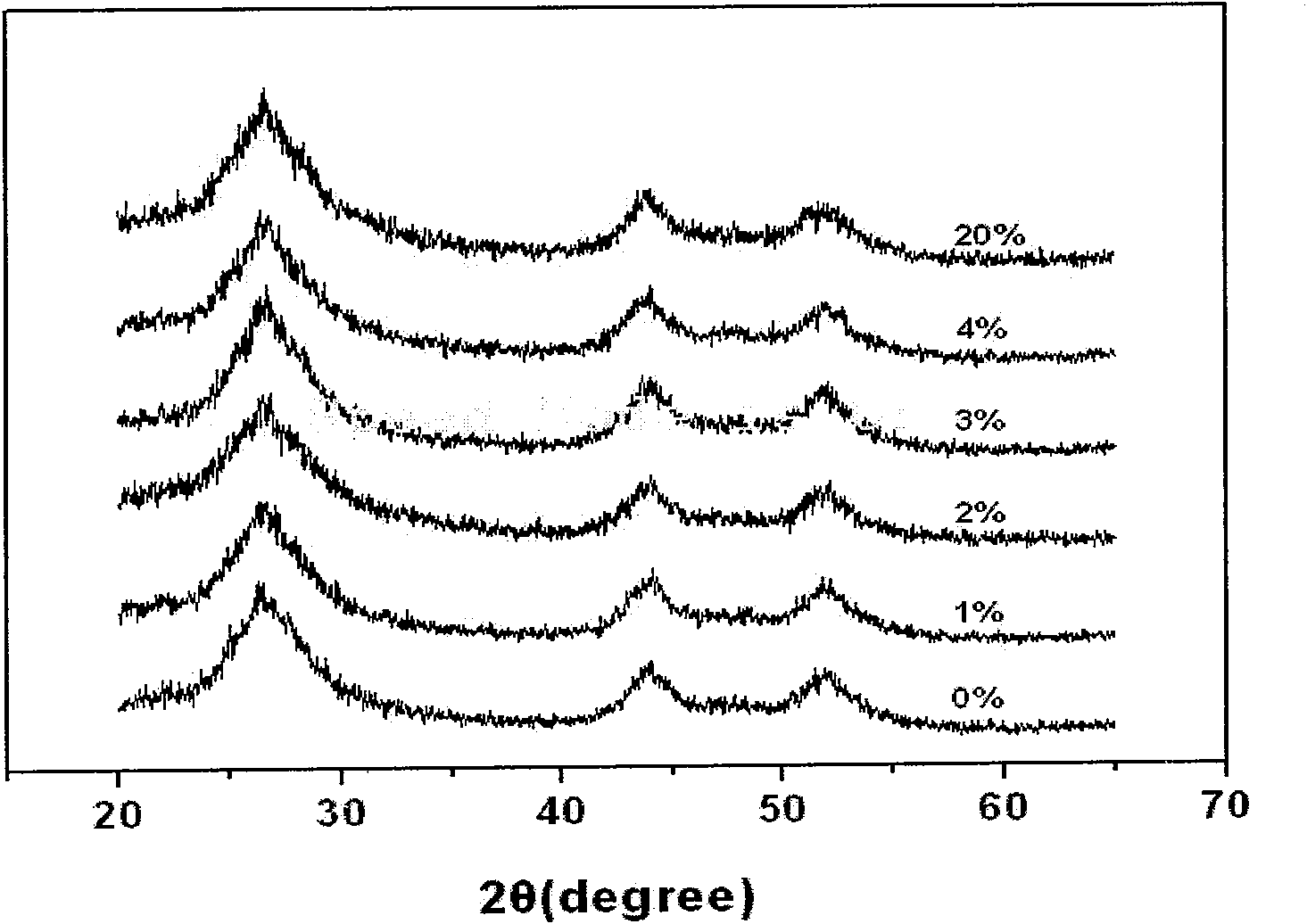

Method for preparing Cd1-xCoxS dilute magnetic semiconductor nanoparticles by gas-liquid surface reaction

A cd1-xcoxs, dilute magnetic semiconductor technology, applied in chemical instruments and methods, cobalt compounds, inorganic chemistry, etc., can solve the problems of small saturation magnetization, affecting the quality of materials, and different particle sizes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0033] Preparation of embodiment 2CdS semiconductor nanoparticles

[0034] First prepare the solution to be reacted: use deionized water and cadmium acetate to prepare the solution containing Cd 2+It is 10mmol / L cadmium ion solution; configure 0.001g / 200mL PVP solution with deionized water and polyvinylpyrrolidone (PVP); extract 10ml of cadmium ion solution, 1ml of PVP solution, and inject 39ml of deionized water into the same beaker to prepare into the liquid to be reacted. The beaker can be placed in the ultrasonic wave for a period of time to make the prepared reaction solution mix evenly. Pour the liquid to be reacted into the dripping funnel, turn on the cooling water at normal temperature, and perform a cooling cycle on the liquid to be reacted to reduce the temperature of the liquid to be reacted.

[0035] Place the reaction chamber in an ultrasonic environment under nitrogen carrying H 2 S enters the reaction chamber. Adjust the liquid to be reacted to make it drop...

Embodiment 3

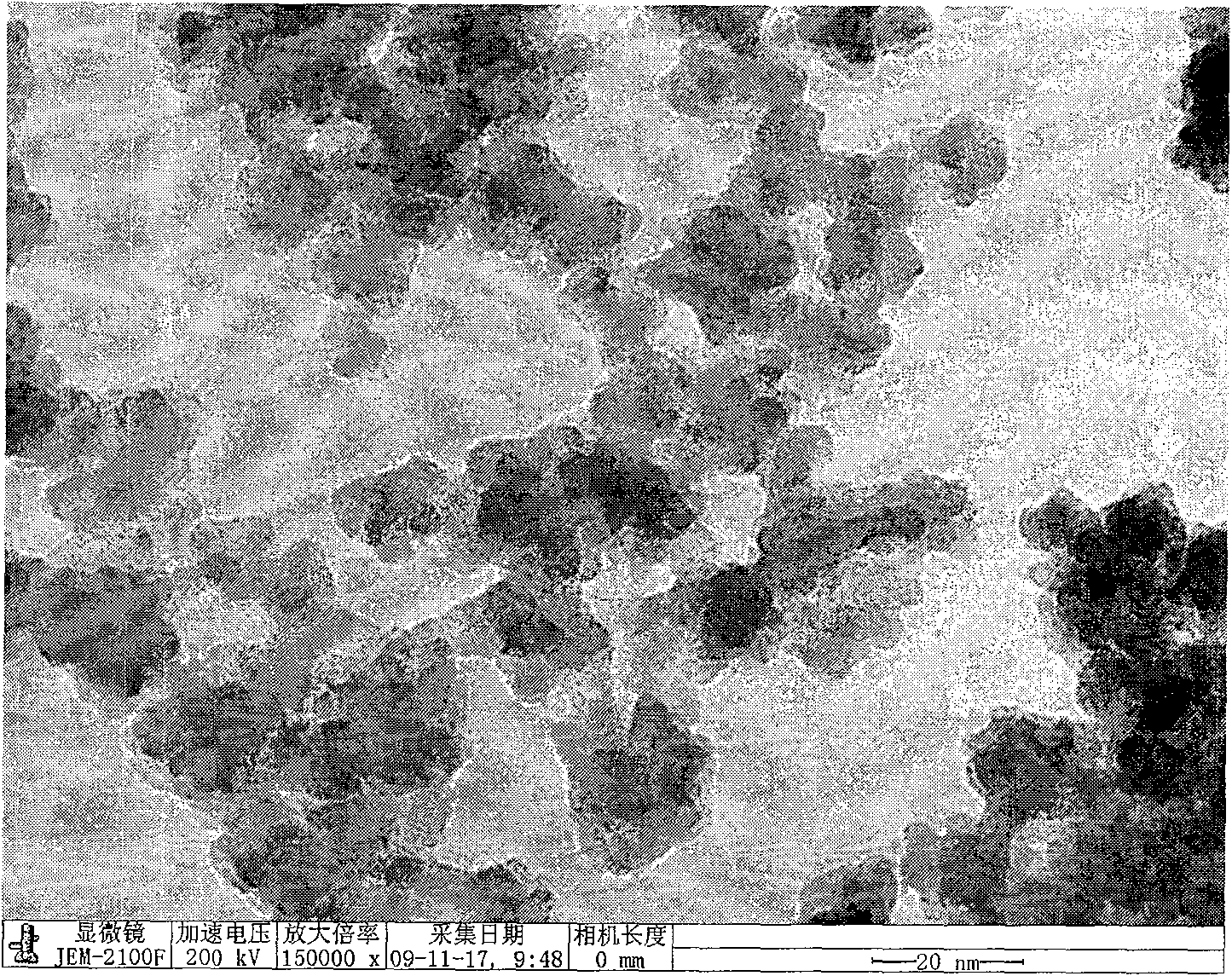

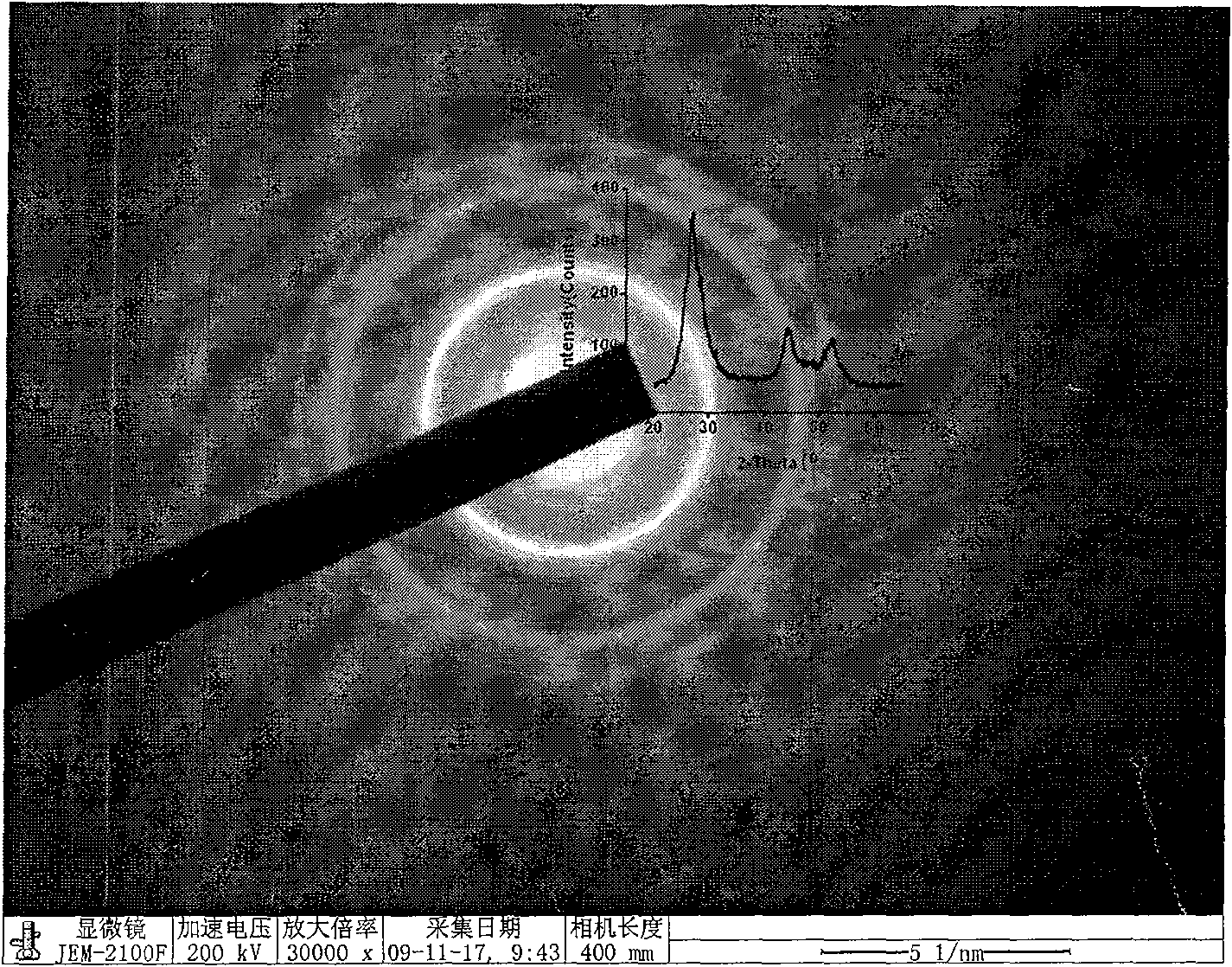

[0038] Example 3Cd 1-x co x Preparation of S Diluted Magnetic Semiconductor Nanoparticles (1)

[0039] First prepare the solution to be reacted: use deionized water and cadmium acetate to prepare the solution containing Cd 2+ 10mmol / L cadmium ion solution; use deionized water and cobalt acetate to prepare Co 2+ 0.2mmol / L cobalt ion solution; use deionized water and PVP to configure 0.001g / 200mL PVP solution; extract 10ml of cadmium ion solution, 5ml of cobalt ion solution, 1ml of PVP solution, and 34ml of deionized water into the same beaker, Prepared to be reacted. The beaker can be placed in the ultrasonic wave for a period of time to make the prepared reaction solution mix evenly. The liquid to be reacted is poured into the dropping funnel, the cooling water at normal temperature is turned on, and the liquid to be reacted is cooled and circulated to lower the temperature of the liquid to be reacted.

[0040] Place the reaction chamber under the sonication environment. ...

Embodiment 4

[0044] Example 4Cd 1-x co x Preparation of S Diluted Magnetic Semiconductor Nanoparticles (2)

[0045] First prepare the solution to be reacted: use deionized water and cadmium acetate to prepare the solution containing Cd 2+ 10mmol / L cadmium ion solution; use deionized water and cobalt acetate to prepare Co 2+ The 2mmol / L cobalt ion solution is configured into a 0.001g / 200mL PVP solution with deionized water and PVP. Extract 10ml of cadmium ion solution, 1ml of cobalt ion solution, 1ml of PVP solution, and inject 38ml of deionized water into the same beaker to prepare the reaction solution. You can put the beaker into the ultrasonic wave for a period of time to make the prepared reaction solution mix evenly . The liquid to be reacted is poured into the dropping funnel, the cooling water at normal temperature is turned on, and the liquid to be reacted is cooled and circulated to lower the temperature of the liquid to be reacted.

[0046] The following reaction process and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com